An automatic detection device for the discharge voltage of an engine ignition nozzle

An automatic detection device and discharge voltage technology, applied in the direction of engine ignition, measuring devices, engine components, etc., can solve problems such as complex operation process, large data deviation, human factor interference, etc., achieve high detection accuracy, eliminate data deviation, and accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

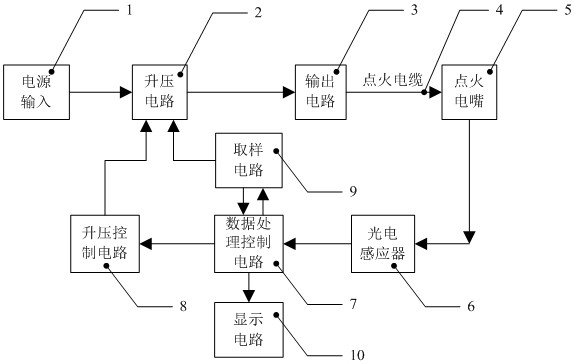

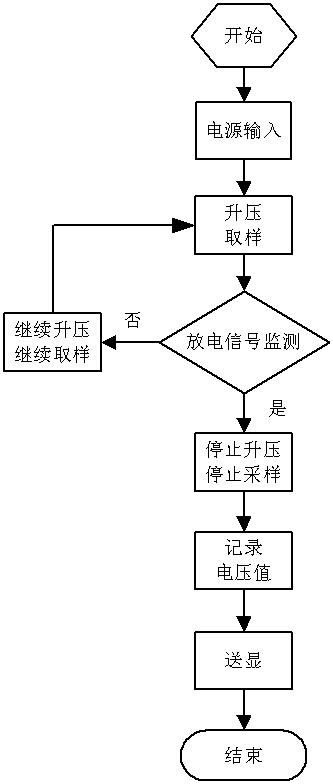

[0020] An automatic detection device for the discharge voltage of an engine ignition nozzle, comprising a boost circuit 2, a boost control circuit 8, a data processing control circuit 7, a photoelectric sensor 6, a sampling circuit 9, and an ignition nozzle 5; the boost circuit 2 The boost control circuit 8 and the sampling circuit 9 are respectively connected, the ignition nozzle 5 is respectively connected to the boost circuit 2 and the photoelectric sensor 6, and the data processing control circuit 7 is respectively connected to the boost control circuit 8, the sampling circuit 9, the photoelectric Inductor 6; the boost control circuit 8 is used to control the voltage rise and fall of the boost circuit 2, the sampling circuit 9 is used to monitor the voltage value of the boost circuit 2, and the photoelectric sensor 6 is used for sensing points Whether there is a discharge spark at the thermal nozzle 5.

[0021] During the use of the present invention, the voltage value of ...

Embodiment 2

[0026] An automatic detection device for the discharge voltage of an engine ignition nozzle, such as figure 1 , figure 2 As shown, it can be used to detect the discharge voltage of the ignition nozzle 5; it includes a booster circuit 2 including a digital control transformer, an output circuit 3, a photoelectric sensor 6 for detecting the discharge state of the ignition nozzle 5, and the voltage of the booster circuit 2 The sampling circuit 9 for monitoring the value, the boost control circuit 8 for controlling the voltage value of the boost circuit 2, the data processing control circuit 7 and the display circuit 10 for displaying the discharge voltage value of the ignition nozzle 5.

[0027] Whether the voltage of the boost circuit 2 rises is controlled by the boost control circuit 8, and the working state of the boost control circuit 8 depends on whether the photoelectric sensor 6 senses the discharge spark of the ignition nozzle 5; The voltage value of the voltage circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com