Method for determining high-temperature interaction reactivity between iron-containing furnace materials of blast furnace

An iron furnace and high temperature technology, which is applied in the field of measuring the high temperature reactivity between iron-containing charges in a blast furnace, can solve the problems of the determination method and evaluation index of the non-high temperature interactive reactivity, and affect the metallurgical properties of the comprehensive charge, so as to reduce energy consumption and reduce The effect of pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

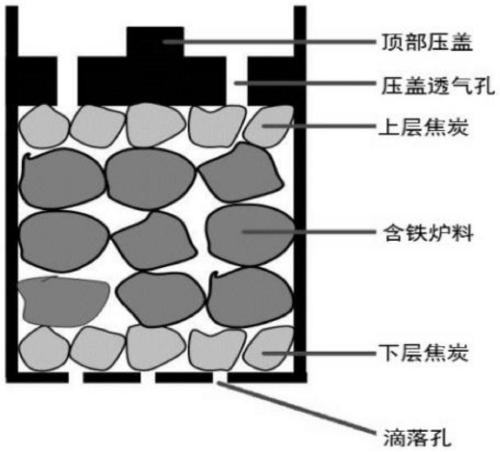

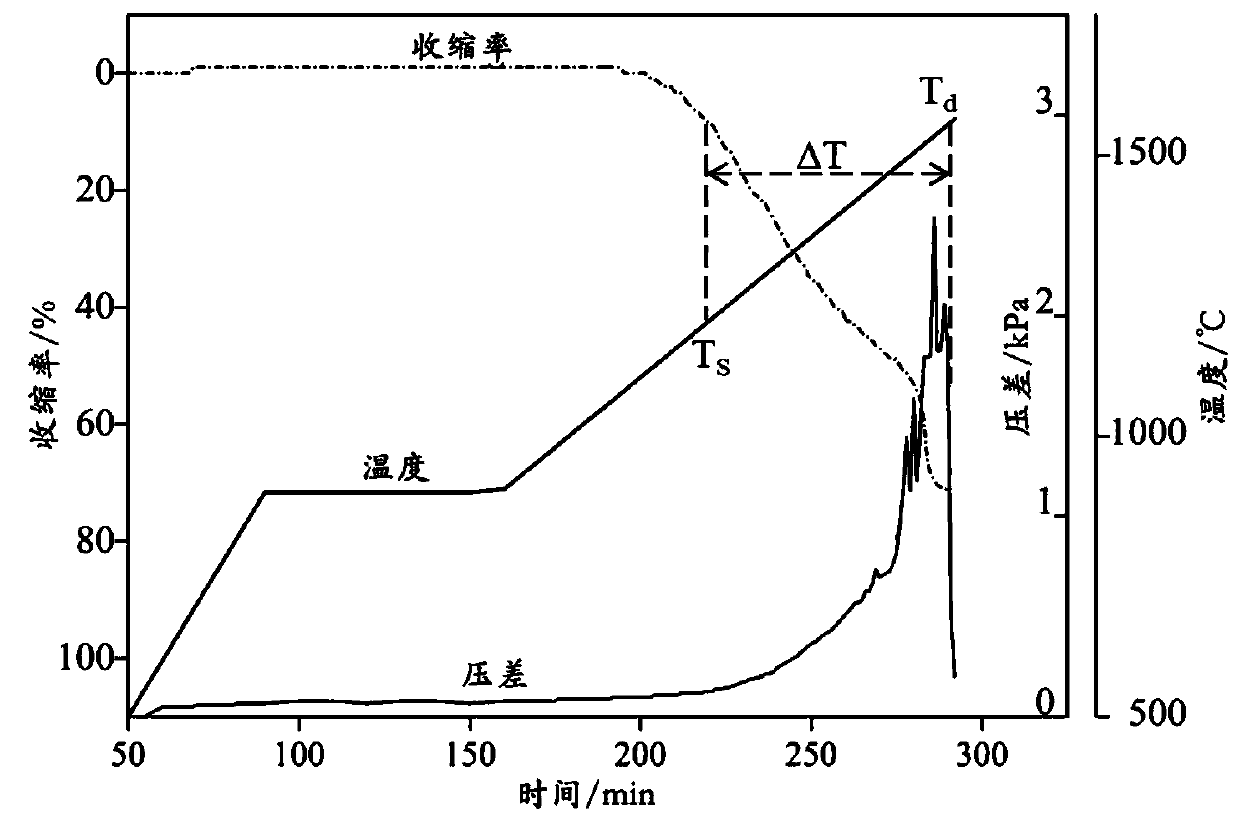

[0052] The method of the present invention can measure the droplet performance of iron-containing charge (sintered ore, pellet ore), according to the droplet curve (such as image 3 shown), the temperature interval T of the melting droplet temperature of a single iron-containing charge is obtained 1 (Sinter droplet temperature range), T 2 (Pellet / lump droplet temperature range).

[0053] After mixing sinter and pellets (or lump ore) according to the ratio of 75%:25%, the same experimental method is used to measure the melting temperature range T of the mixed charge. 0 .

[0054] (1) Sample composition

[0055]

[0056] (2) Experimental procedure: Take 200g each of sinter, pellets and lump ore with a particle size of 10-12.5mm after drying, and conduct a single iron-containing charge droplet experiment; take 150g of sinter and 50g of pellet / lump , to form a mixed charge, and carry out the droplet experiment of the mixed charge; according to the temperature-pressure diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com