Test tube cleaning device for clinical laboratory

The invention relates to a cleaning device and a technology of inspection department, which is applied in the field of inspection department and can solve the problems of difficulty in timely discharge, inability to clean the outer wall of the test tube, low cleaning efficiency, etc., and achieves the effect of improving efficiency, improving cleaning efficiency and ensuring cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

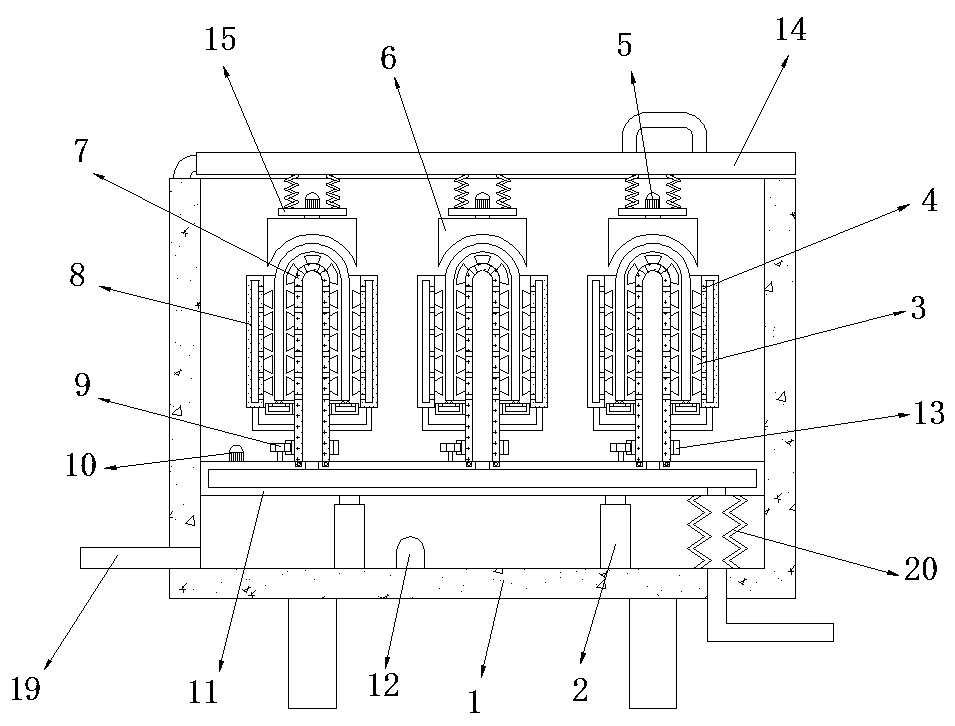

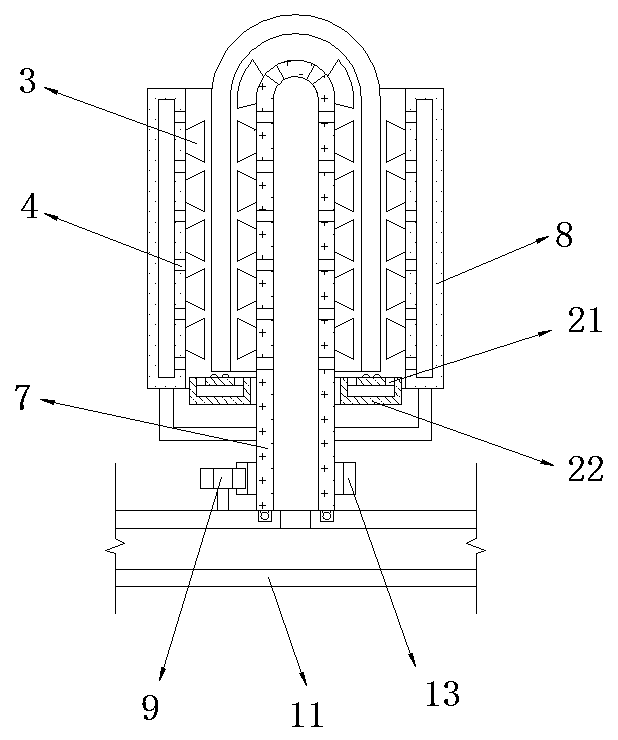

[0028] refer to Figure 1-3 , a test tube cleaning device for laboratory, including a box body 1, the bottom inner wall of the box body 1 is connected with a first electric telescopic rod 2 through a fastening bolt, and one end of the first electric telescopic rod 2 is connected with a lifting rod through a fastening bolt The pipe 11, the top of the lifting pipe 11 is plugged with evenly distributed outlet pipes 7, and the bottom of the outer wall of the outlet pipe 7 is connected to the limit ring 8 by fastening bolts, and the outer wall of the outlet pipe 7 and the inner wall of the limit ring 8 are provided with Evenly distributed water outlet holes 4, the bottom of the outer wall of the outlet pipe 7 is connected with a support plate 22 by fastening bolts, and the top of the support plate 22 is provided with evenly distributed perforations 21, and the inner wall of the bottom of the box body 1 is connected with a water pump by fastening bolts 12. The outer wall of the bott...

Embodiment 2

[0036] refer to figure 1 and Figure 4, a test tube cleaning device for laboratories. Compared with Embodiment 1, the tops of the inner walls on both sides of the outlet pipe 7 are connected with the same fixed rod 18 by fastening bolts, and the top of the fixed rod 18 is connected by fastening bolts. Connected with a second electric telescopic rod 17, one end of the second electric telescopic rod 17 is connected with an extension rod 16 by a spring, and the end of the extension rod 16 extending to the top outer wall of the outlet pipe 7 is connected with bristles by fastening bolts.

[0037] Working principle: when cleaning, the second electric telescopic rod 17 can reciprocate the extension rod 16, and the extension rod 16 pushes the test tube to reciprocate in the vertical direction to ensure the cleaning effect of the test tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com