A Thickness Control Method of 1720mm Strip Steel Continuous Cold Rolling Mill

A cold tandem rolling mill and thickness control technology, applied in the rolling mill control device, rolling force/roll gap control, metal rolling, etc., can solve the problem of response time, etc., and achieve the effect of reducing the lag time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

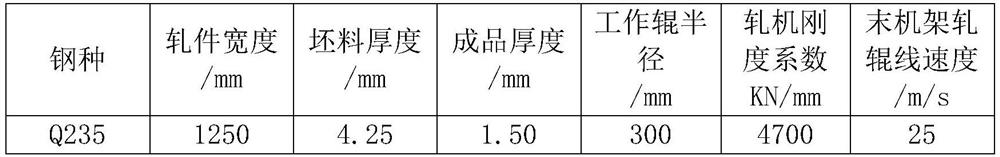

[0045] In this embodiment, strip steel with a thickness of 4.25mm is selected to produce finished strip steel with a thickness of 1.5mm. The raw material specification is 1250×4.25mm, the steel type is Q235, and the pre-compression force P is set. 0 It is 10000KN, the radius of the work roll is 300mm, and the exit speed of the fifth rack is 25m / s.

[0046] As shown in the following table:

[0047] Table I

[0048]

[0049](Regression coefficient: a1=88.75; a2=69398.43; a3=6669.42; a4=0.568)

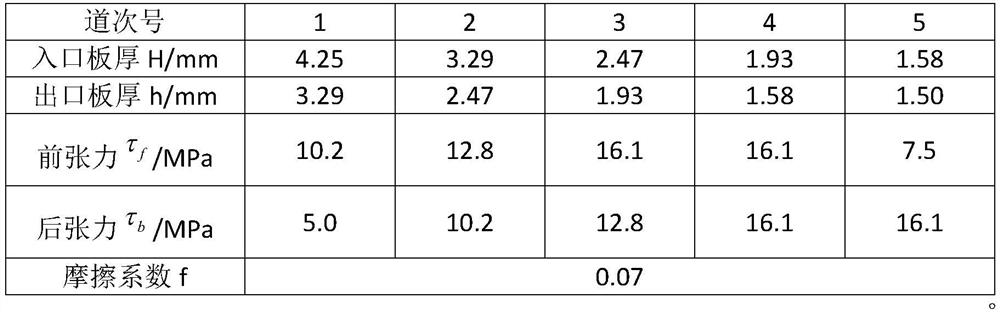

[0050] Table II

[0051]

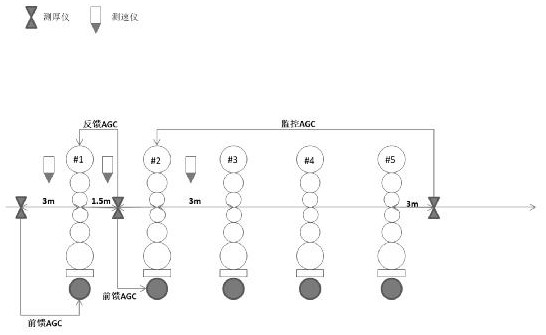

[0052] to combine figure 1 As shown, a 1720mm strip steel tandem cold rolling mill thickness control method adopts a 1720mm strip steel tandem cold rolling mill, including the first stand, the second stand, the third stand, the fourth stand, and the fifth stand ; The rolled piece p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com