System and method for rapid solidification of large-sized metal droplets suspended in microgravity

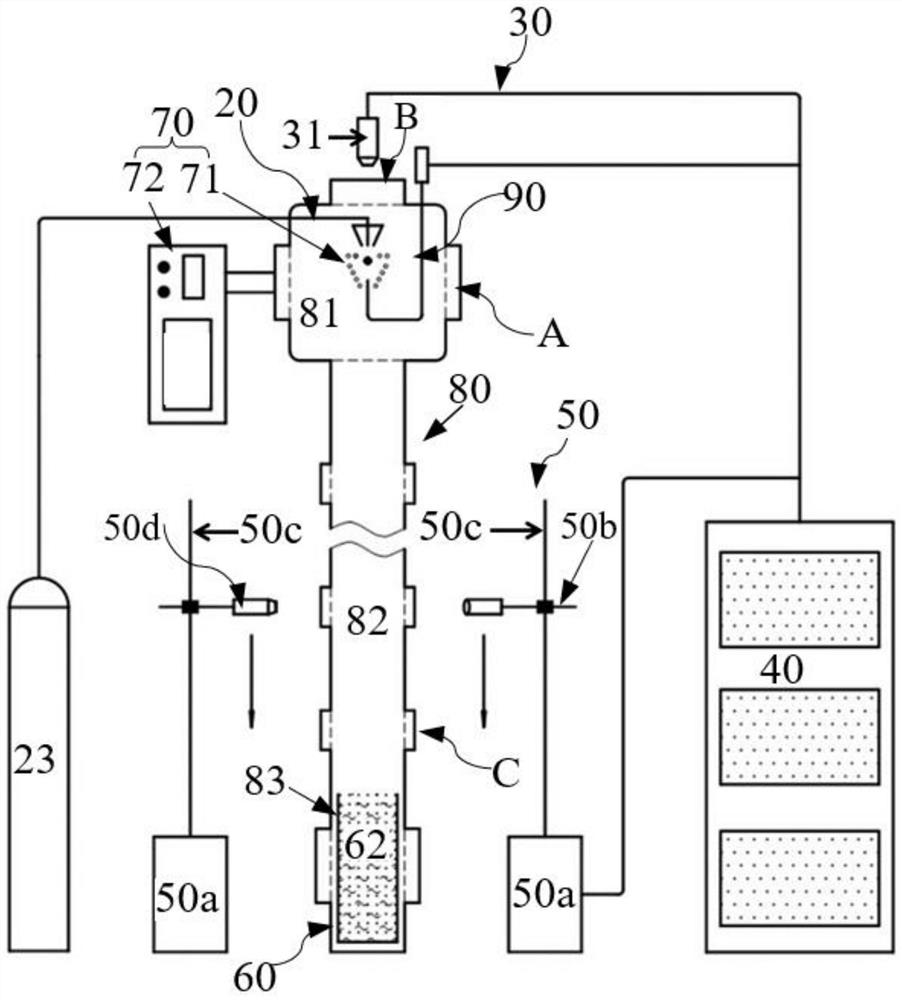

A metal droplet and microgravity technology, which is applied in the field of space material science, can solve the problems that the temperature of falling droplets cannot be continuously and dynamically collected, and the size of alloy samples is small, so as to achieve uniform solidification structure, avoid reaction, and inhibit segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] The experimental steps of this embodiment are as follows:

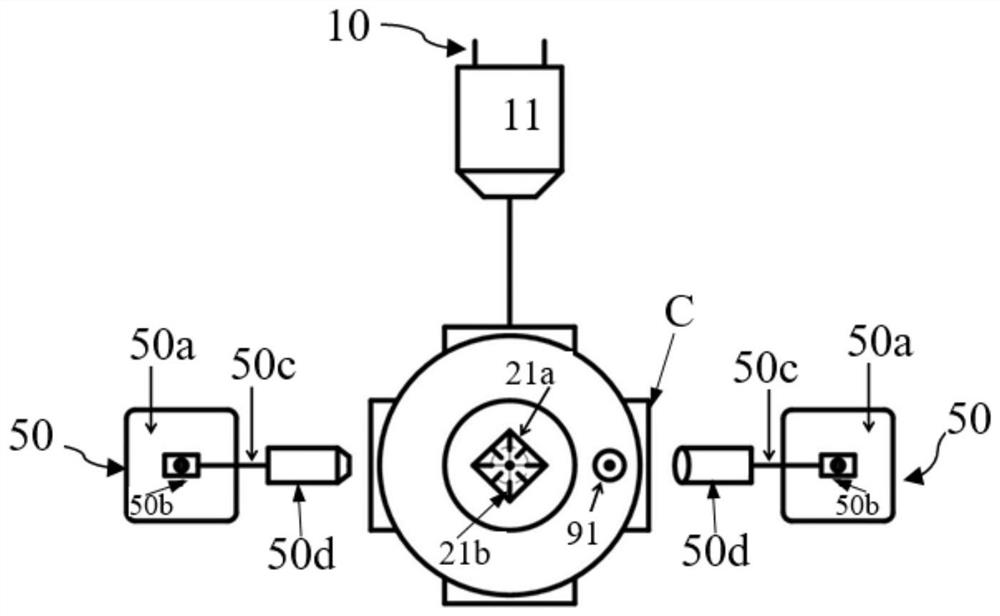

[0099] S1: Accurately weigh raw materials according to the mass percentage of Ti-6%Al-4%V, and prepare alloy samples by arc melting method under inert gas protection conditions. The alloy sample is about 0.3 cm in diameter.

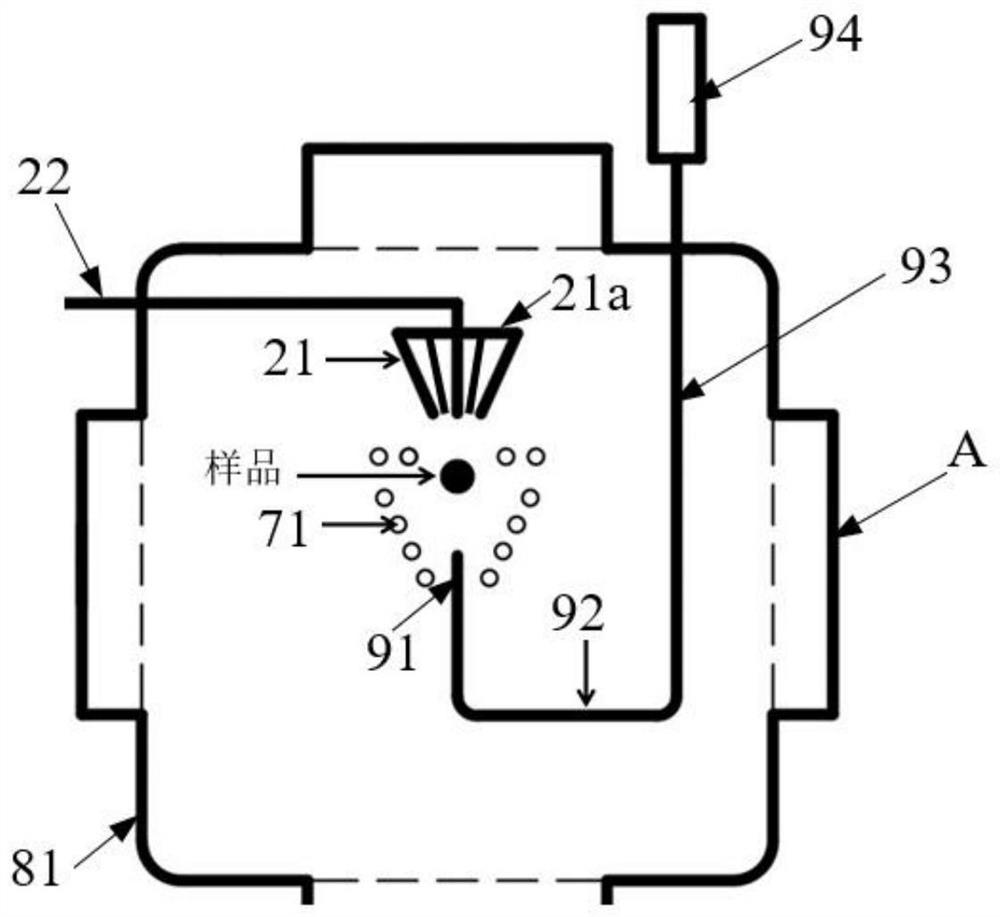

[0100] S2: Turn on the control system 40, rotate the control rod 93 of the sample feeding device 90, and put the alloy sample on the top surface of the sample feeding rod 91. A quenching medium container 61 is placed at the bottom of the vacuum cavity 80, and a quenching cooling medium 62 is contained in the container. The quenching cooling medium 62 is silicon oil. After the alloy sample is sent to the center of the suspension induction coil 71, the vacuum chamber 80 is evacuated to 2×10 by the vacuum system 10 -5 Pa. Close the vacuum system 10, and backfill the vacuum chamber 80 with inert gas to a standard atmospheric pressure. The inert gas is a mixed gas of argon and helium.

[...

Embodiment 2

[0104] The experimental steps of this embodiment are as follows:

[0105] S1: According to Co 50 Cu 50 Raw materials are accurately weighed by atomic percentage, and alloy samples are prepared by arc melting method under inert gas protection conditions. The alloy sample is about 1 cm in diameter.

[0106] S2: Turn on the control system 40, rotate the control rod 93 of the sample feeding device 90, and put the alloy sample on the top surface of the sample feeding rod 91. A quenching medium container 61 is placed at the bottom of the vacuum cavity 80, and a quenching cooling medium 62 is contained in the container. The quenching cooling medium 62 is liquid metal. After the alloy sample is sent to the center of the suspension induction coil 71, the vacuum chamber 80 is evacuated to 6×10 by the vacuum system 10 -6 Pa. Close the vacuum system 10, and backfill the vacuum chamber 80 with inert gas to a standard atmospheric pressure. The inert gas is helium.

[0107] S3: Turn ...

Embodiment 3

[0110] The experimental steps of this embodiment are as follows:

[0111] S1: According to Ni 45 Fe 40 Ti 15 Raw materials are accurately weighed by atomic percentage, and alloy samples are prepared by arc melting method under inert gas protection conditions. The alloy sample is about 2 cm in diameter.

[0112]S2: Turn on the control system 40, rotate the control rod 93 of the sample feeding device 90, and put the alloy sample on the top surface of the sample feeding rod 91. A quenching medium container 61 is placed at the bottom of the vacuum cavity 80, and a quenching cooling medium 62 is contained in the container. The quenching cooling medium 62 is silicon oil. After the alloy sample is sent to the center of the suspension induction coil 71, the vacuum chamber 80 is evacuated to 9×10 by the vacuum system 10 -7 Pa. Close the vacuum system 10, and backfill the vacuum chamber 80 with inert gas to a standard atmospheric pressure. The inert gas is helium, a mixed gas of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com