Steel component length fixing mechanism

A steel member, fixed-length technology, used in positioning devices, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of low measurement and positioning work efficiency of steel members, unfavorable cutting of steel members, and low cutting accuracy. , to reduce the difficulty of operation, reduce cutting errors, and improve positioning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

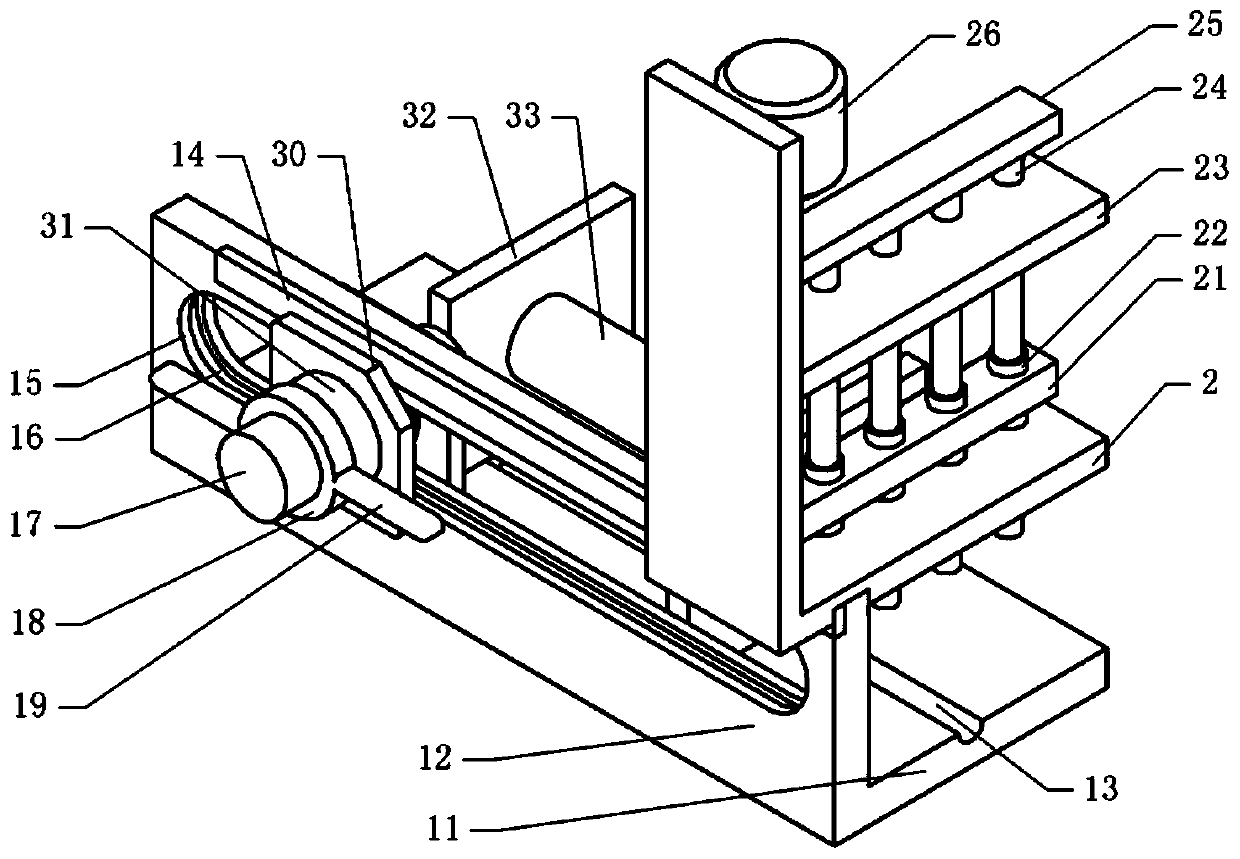

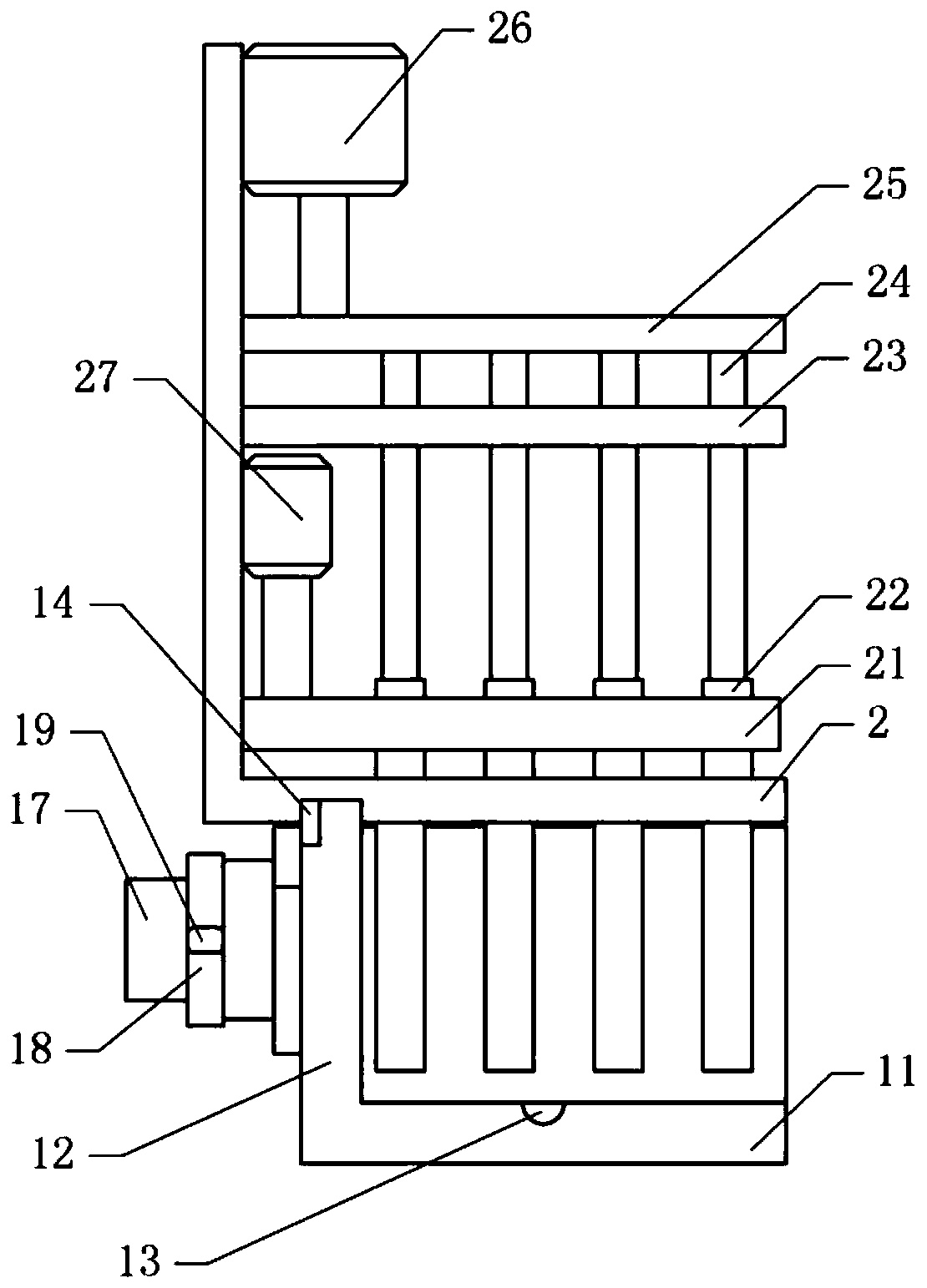

[0041] Basic as attached figure 1 , attached figure 2 And attached image 3 As shown, a length-fixing mechanism for steel members includes a first plate 11 and a second plate 12 integrally formed with the first plate 11, and the first plate 11 and the second plate 12 form an L-shaped plate.

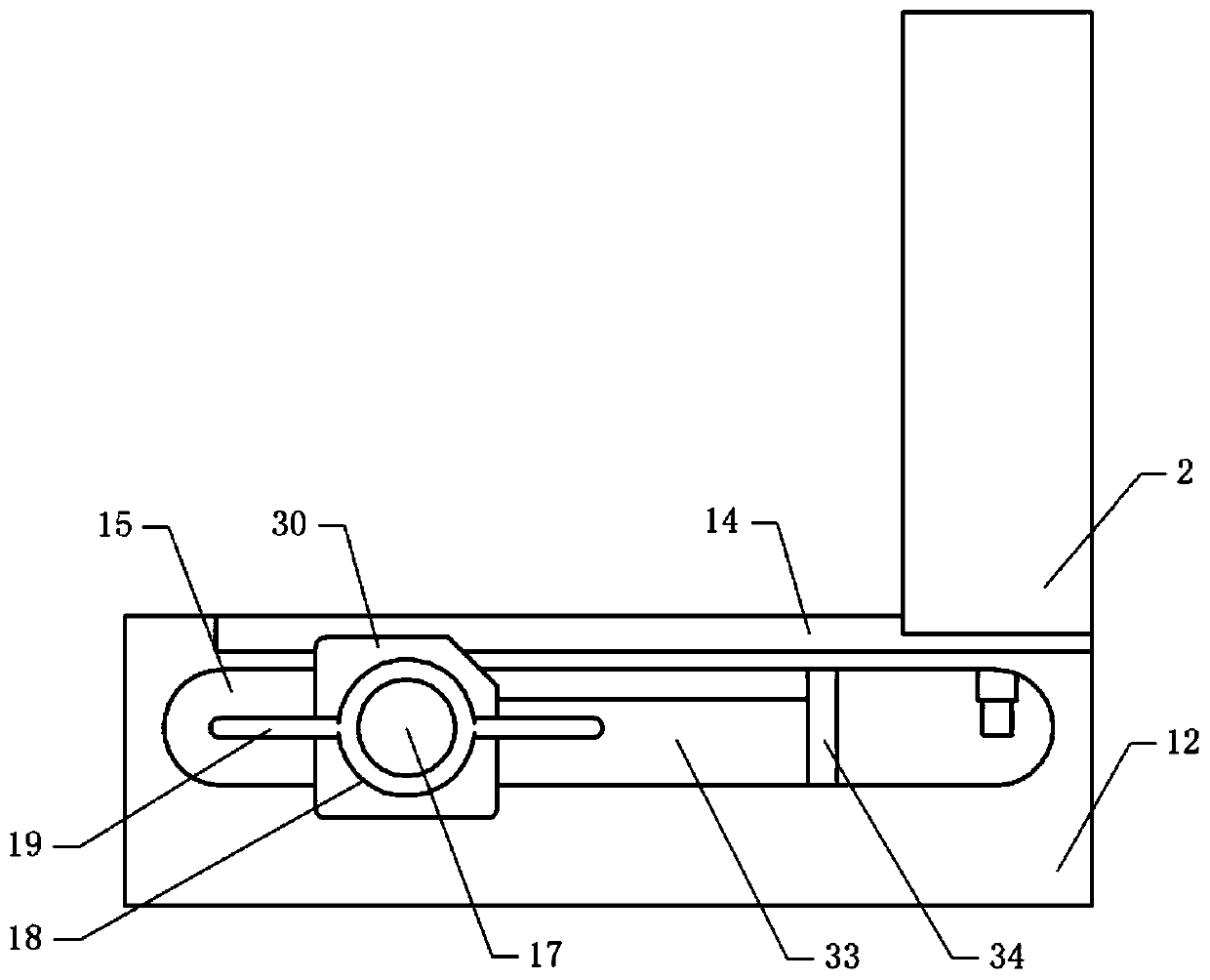

[0042] The middle part of the second plate 12 has a chute 15, and the side wall of the chute 15 has a ball groove 16, and the horizontal sliding in the chute 15 is connected with a positioning shaft 17, and the positioning shaft 17 can slide along the width direction of the chute 15. combined with Figure 5 As shown, a ball 36 is welded on the positioning shaft 17, and the ball 36 is slidingly matched with the ball groove 16, and there is a certain distance between the ball 36 and the ball groove 16.

[0043] as attached Figure 4 As shown, the positioning shaft 17 is sequentially provided with a pressing shaft 18 , a pressing shaft 31 , two clamping pieces and a first pressing plate...

Embodiment 2

[0053] The difference between embodiment two and embodiment one is that, as attached Figure 6 And attached Figure 7 As shown, the auxiliary shaft 24 is provided with a liquid channel 241 and has openings at both ends. The auxiliary shaft 24 includes an upper section and a lower section located in the fixed shaft 22. A bellows is arranged between the upper section and the lower section. The upper end of the bellows and the upper section are fastened The bolts are fixedly connected, the lower end of the bellows and the lower section are fixedly connected by fastening bolts, and the bellows connects the upper section and the lower section. The fixed shaft 22 is provided with a number of injection holes 221 along its axial direction, and the lower section is provided with a number of liquid holes communicating with the injection holes 221 along its axial direction.

[0054] The second sliding plate 25 is provided with a cavity 251 communicating with the upper section. The cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com