A design method for the shape of rubber winding forming pressure roller

A design method and winding molding technology, applied in the field of rubber winding molding, can solve the problems affecting the winding quality and bonding quality, winding tape warping, small winding pressure, etc., so as to improve the winding pressure and winding quality, reduce the winding pressure, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

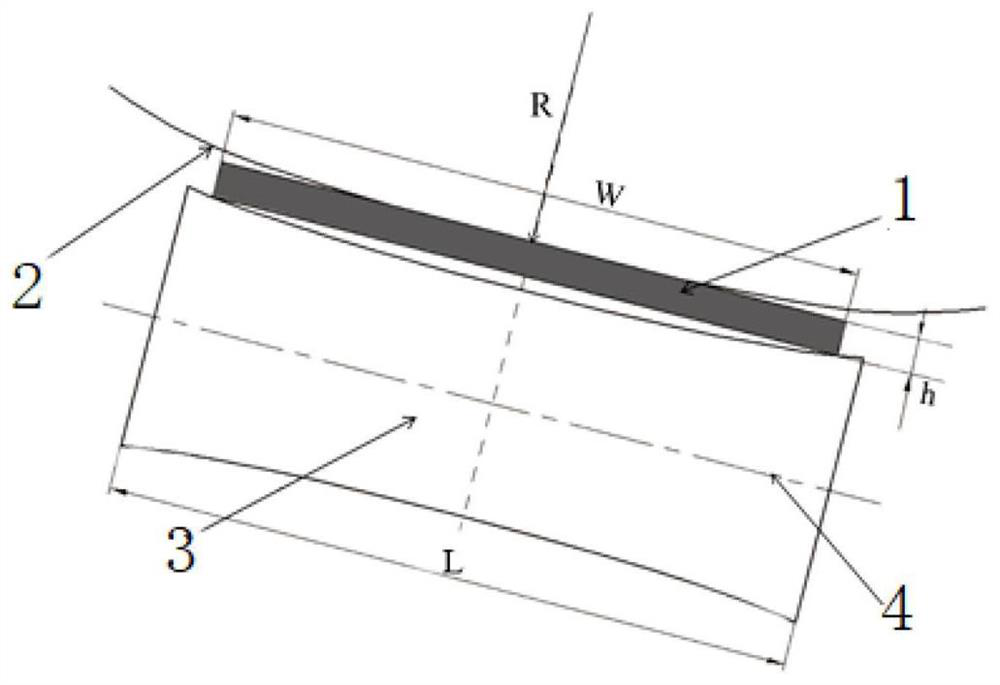

[0024] This embodiment relates to a method for designing the shape of a solid rocket motor heat insulation layer winding forming pressure roller:

[0025] In this embodiment, the diameter range of mandrels of different solid rocket motor models is: 480mm-2000mm. According to the above, the minimum model mandrel diameter of 480mm is selected to design the shape of the winding pressure roller. The mandrel radius R=240mm, the tape width W=100mm.

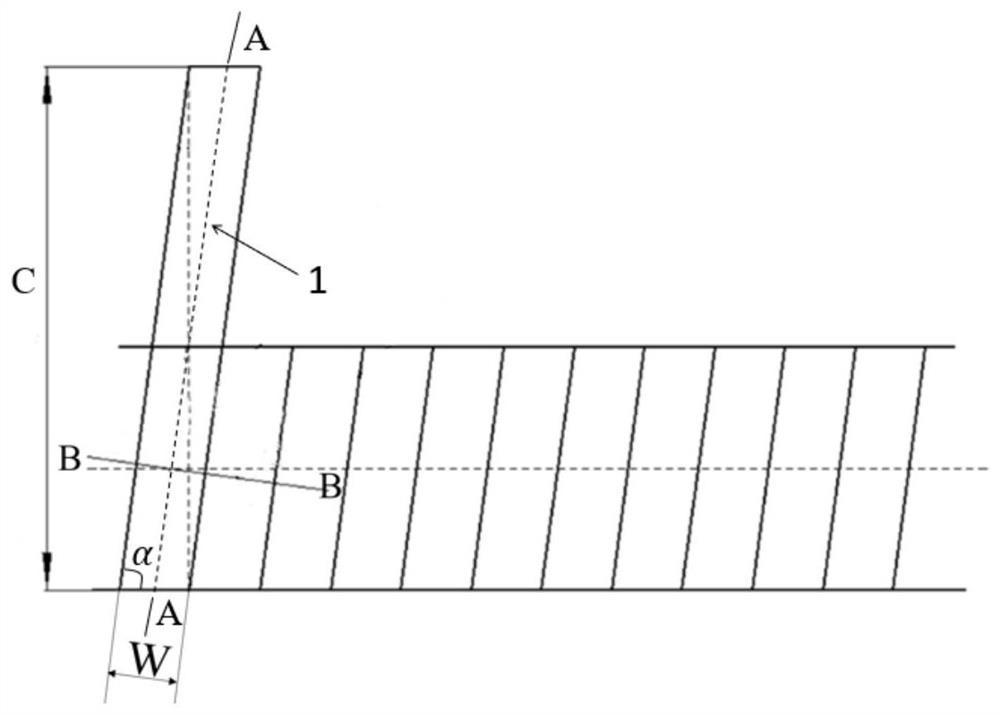

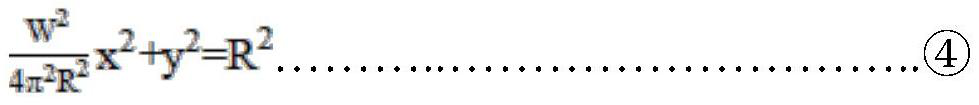

[0026] (1) if figure 1 , figure 2 As shown, according to the width W of the rubber tape and the radius R of the mandrel, the winding angle α is calculated as:

[0027] C=2πR................................................ .....①

[0028] α=arc cos(W / C)................................... ..........②

[0029] That is, C=1507.20mm, α=86.20°.

[0030] (2) if figure 1 As shown, the tape is wound al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com