Electric vehicle battery thermal management method, electronic equipment and vehicle

A technology for battery thermal management, electric vehicles, applied in the automotive field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

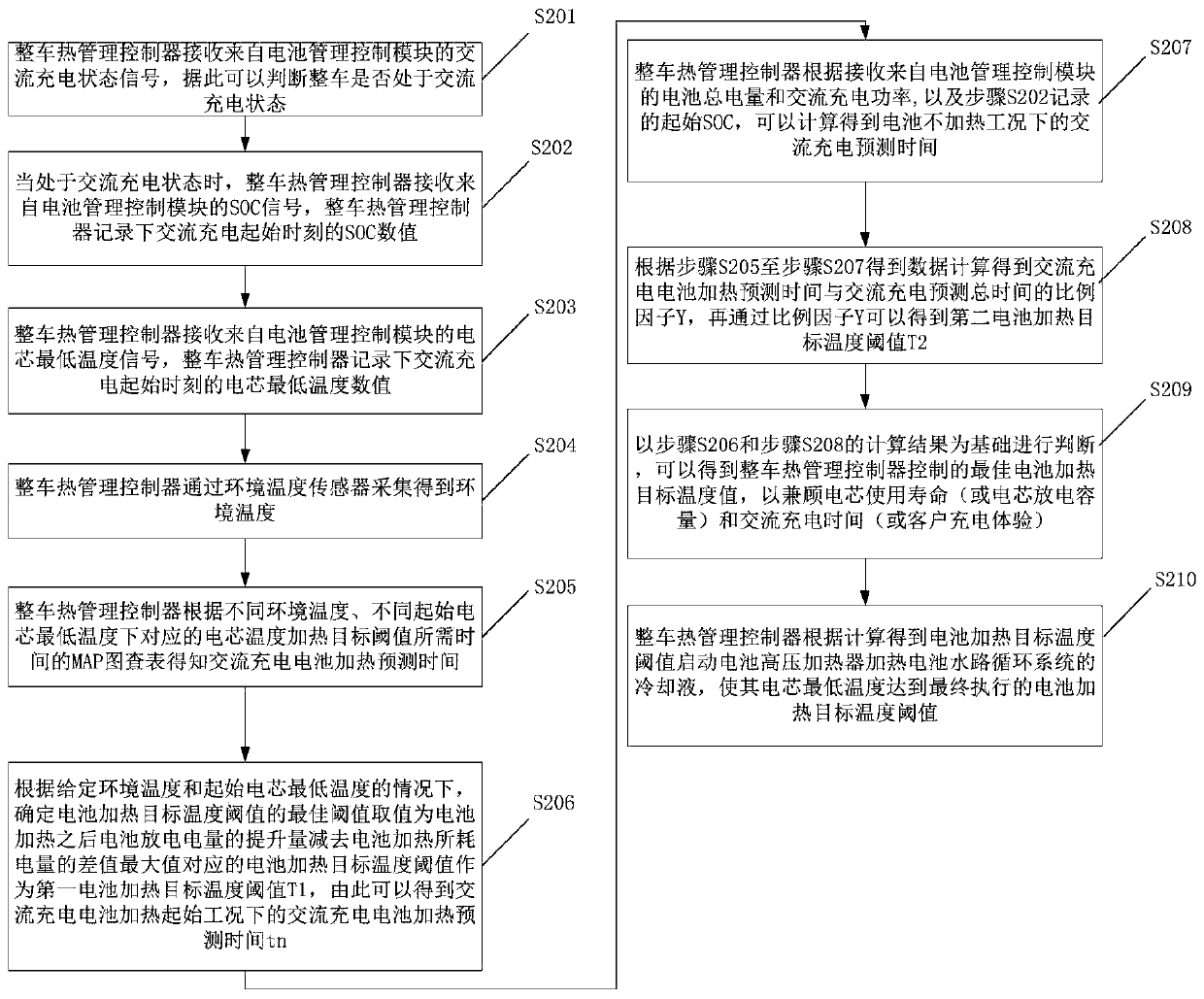

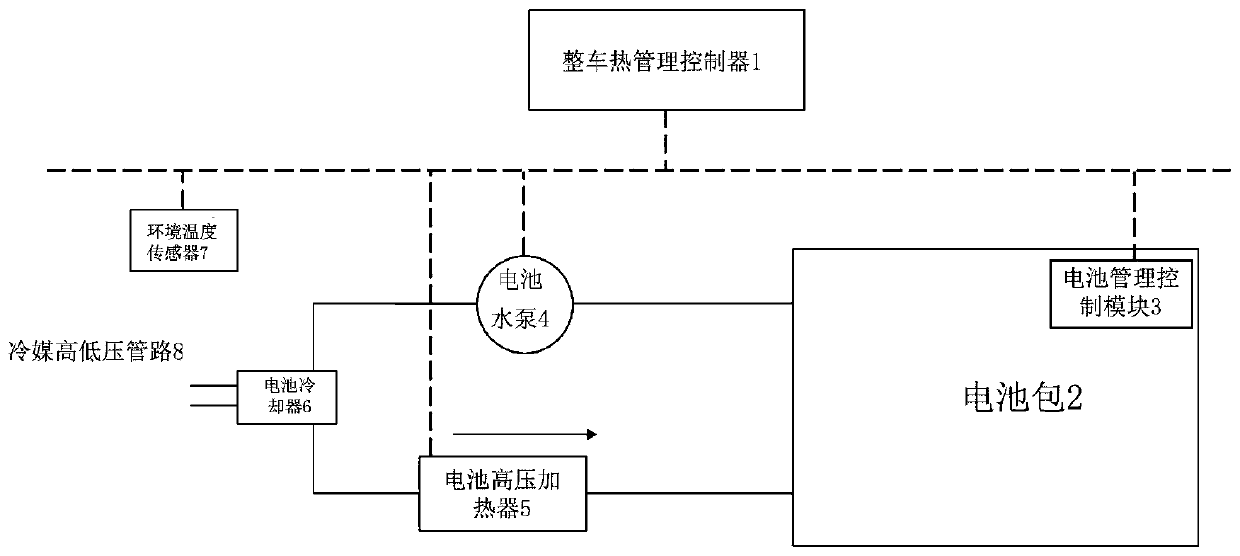

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

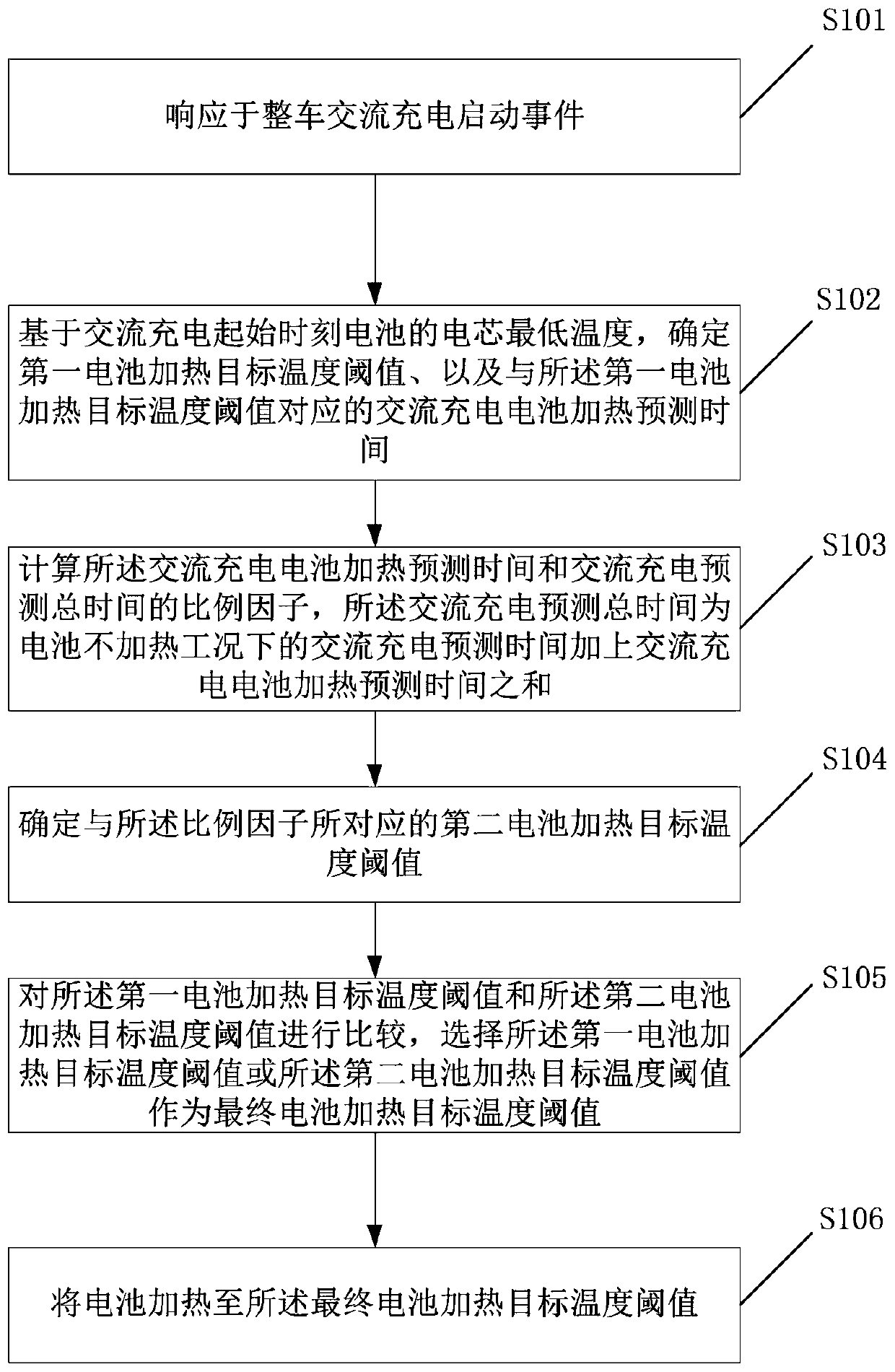

[0062] like figure 1 Shown is a working flow chart of an electric vehicle battery thermal management method according to an embodiment of the present invention, including:

[0063] Step S101, responding to the vehicle AC charging start event;

[0064] Step S102: Determine a first battery heating target temperature threshold and an AC rechargeable battery heating prediction time corresponding to the first battery heating target temperature threshold based on the lowest cell temperature of the battery at the start of AC charging;

[0065] Step S103, calculating a proportional factor between the predicted heating time of the AC rechargeable battery and the total predicted time of AC charging, the total predicted time of AC charging being the difference between the predicted time of AC charging under the condition that the battery is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com