A connector and a wiper

A connector and wiper arm technology, used in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., can solve problems such as safety accidents, smashed windshields of vehicles, failures, etc., and achieve the effect of ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

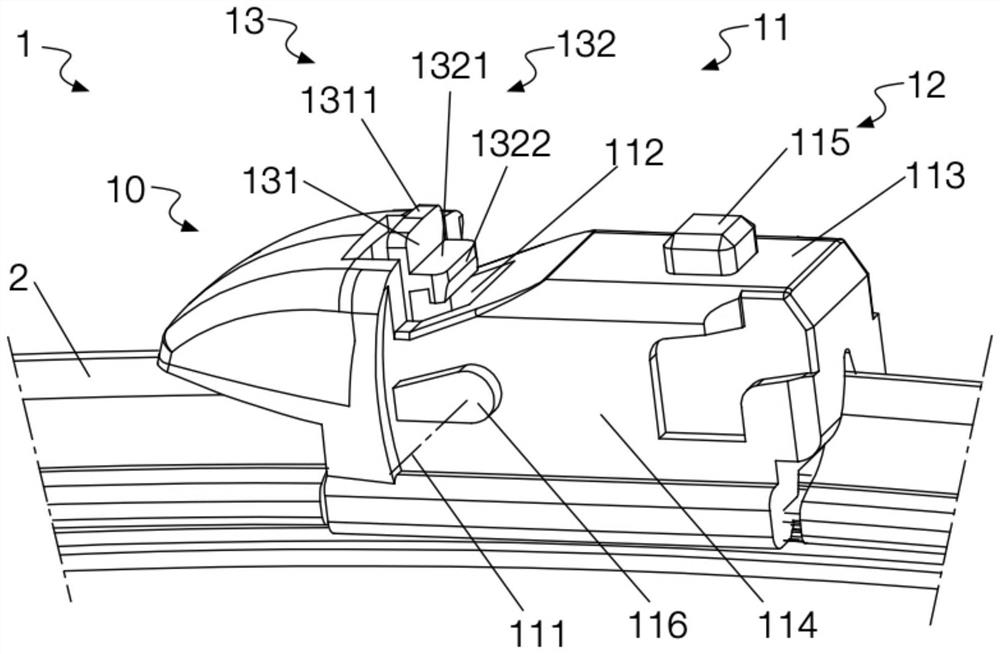

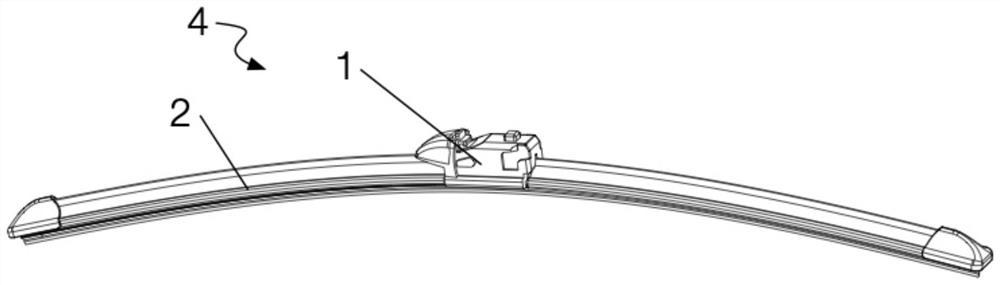

[0087] see figure 1 , figure 1 The connector 1 in the first embodiment is shown. The connector 1 is used to ensure the hinge relationship between the wiper blade 2 and the wiper arm 3 (see Figure 4 ).

[0088] Such as figure 1 As shown, the connector 1 in the first embodiment includes a fixing member 10 fixedly connected with the wiper blade 2 .

[0089] The fixing part 10 is provided with a body 11 , a blocking part 12 and a deforming part 13 .

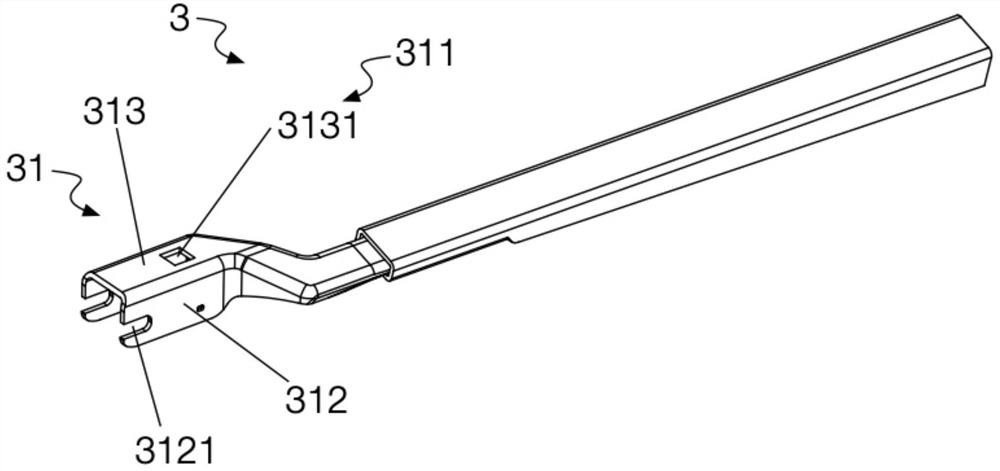

[0090] Wherein, the main body 11 has two side surfaces 114 , a top surface 113 and a concave portion 112 . Protruding shafts 116 extending to both sides are provided on the two side surfaces 114 . The protruding shaft 116 is used to establish a hinge relationship with the wiper arm 3 to form a rotating shaft 111 for rotating the wiper arm 3 around the main body 11 . At the rear of the rotating shaft 111, the top surface 113 is provided with a first protrusion 115, the first protrusion 115 forms the aforementioned blocking por...

Embodiment 2

[0107] see Figure 8 and Figure 9 , Figure 8 The connector 1 in the second embodiment is shown. The connector 1 is used to ensure the hinge relationship between the wiper blade 2 and the wiper arm 3 (see Figure 11 ).

[0108] Such as Figure 8 As shown, the connector 1 in the second embodiment includes a fixed piece 10 fixedly connected with the wiper blade 2 , and a rotating piece 20 rotatably connected with the fixed piece 10 relative to the rotating shaft 111 .

[0109] Such as Figure 9 As shown, the fixing part 10 is provided with a body 11 , a blocking part 12 and a deforming part 13 .

[0110] Wherein, the main body 11 has two side surfaces 114 , a top surface 113 and a concave portion 112 . A rotating shaft 111 rotatably connected to the rotating member 20 is defined on the two side surfaces 114 . At the rear of the rotating shaft 111, the top surface 113 is provided with a first protrusion 115, the first protrusion 115 forms the aforementioned blocking port...

Embodiment 3

[0128] see Figure 16 , Figure 16 The connector 1 in the third embodiment is shown. The connector 1 is used to ensure the hinge relationship between the wiper blade 2 and the wiper arm 3 (see Figure 18 ).

[0129] Such as Figure 16 As shown, the connector 1 in the third embodiment includes a fixed piece 10 fixedly connected with the wiper blade 2 , and a rotating piece 20 rotatably connected with the fixed piece 10 relative to the rotating shaft 111 .

[0130] Wherein, the fixing member 10 is the same as Figure 9 The fixing member 10 in the second embodiment shown is completely the same, and will not be repeated here.

[0131] Such as Figure 16 As shown, the rotating member 20 is basically the same as the rotating member 20 in the second embodiment, the only difference is that in the third embodiment, the top wall 21 of the rotating member 20 is configured as a hinged relationship between the wiper blade 2 and the wiper arm 3 , the limiting surface 1321 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com