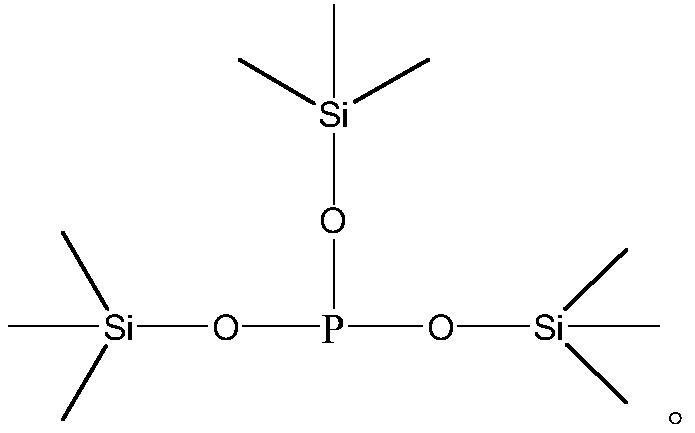

A kind of synthetic method of three (trimethylsilyl) phosphites

A technology of trimethylsilyl and phosphite, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of expensive, easy hydrolysis, and increased post-processing steps and other problems, to achieve the effect of simple post-processing steps, mild reaction conditions and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a 2000mL three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 650g of hexamethyldisilazane, 10g of D002 type strong acidic styrene-based cationic resin, raise the temperature to 80°C, and add phosphorous acid-acetonitrile dropwise The solution (200 g of phosphorous acid, 300 g of acetonitrile) was added dropwise in 2 hours. After the dropwise addition, it was kept at 90° C. for 1 hour to complete the reaction. 1090 g of reaction liquid was obtained, including 670 g of tris(trimethylsilyl)phosphite, and the conversion rate was 92.2%.

Embodiment 2

[0020] In a 2000mL three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 600g of hexamethyldisilazane, 20g of D62 type strong acidic styrene-based cation exchange resin, raise the temperature to 50°C, and dropwise add phosphorous acid- N,N-dimethylformamide solution (phosphorous acid 200g, N,N-dimethylformamide 400g), the dropwise addition was completed in 2 hours, after the dropwise addition, it was kept at 50° C. for 2 hours, and the reaction was completed. 1147 g of reaction liquid was obtained, including 618 g of tris(trimethylsilyl)phosphite, and the conversion rate was 85.0%.

Embodiment 3

[0022] In a 5000mL three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 500g of hexamethyldisilazane, 7g of 734-type strong acidic styrene-based cation exchange resin, raise the temperature to 90°C, and dropwise add phosphorous acid- Diethylene glycol dimethyl ether solution (phosphorous acid 200g, diethylene glycol dimethyl ether 200g), was added dropwise in 1 hour. After the dropwise addition was completed, it was incubated at 90° C. for 1 hour, and the reaction was completed. 850 g of reaction liquid was obtained, including 537 g of tris(trimethylsilyl)phosphite, and the conversion rate was 87.0%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap