Biomass charcoal for improving saline alkali soil, preparation method, and preparation of derivative of biomass charcoal and application thereof

A biomass charcoal and saline-alkali soil technology, applied in the restoration, application, soil conditioning materials and other directions of polluted soil, can solve the problems such as being unsuitable for large-scale transformation of saline-alkali soil, high cost, and time-consuming, and achieve improved structure and Organic carbon stocks, effects on germination and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

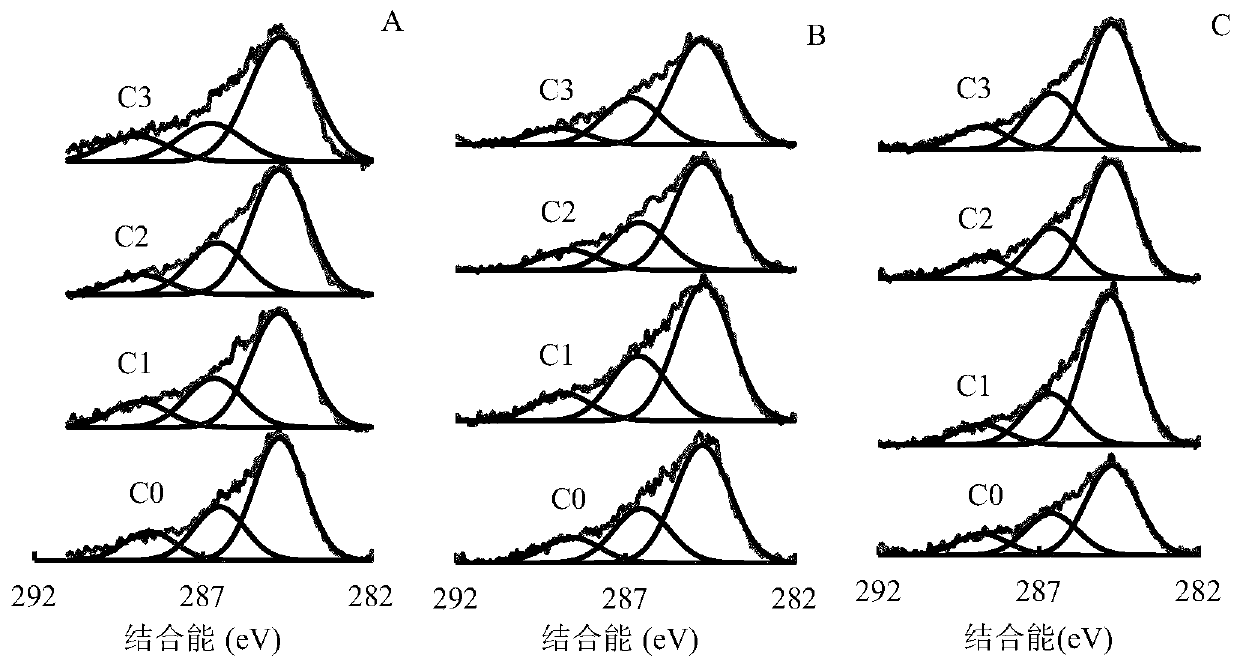

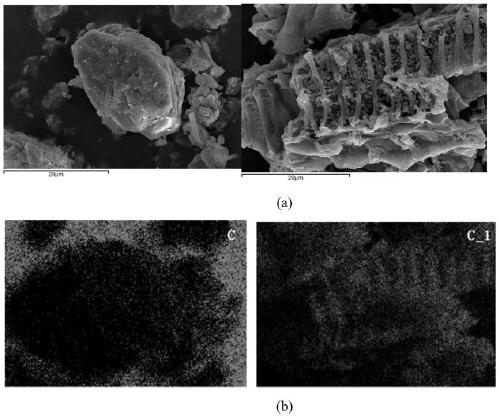

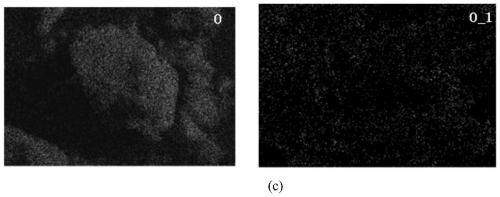

[0025] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] 1. Preparation of biochar and its derivative products

[0027] 1.1 The present invention provides a method for utilizing tidal flat plants to produce improved saline-alkali soil biochar, and the specific steps are as follows:

[0028] (1) Collect tidal flat plants such as reeds and Spartina alterniflora.

[0029] (2) Air-dry the tidal flat plants until the water content is <25%, and then crush them and screen them through a sieve with a mesh size of no more than 5 mm to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com