Attached type ship-collision-prevention structure of steel-concrete combined structure

A combined structure and concrete technology, applied in bridge parts, bridge materials, climate change adaptation and other directions, can solve the problems of difficult metal materials, thin structure, easy to appear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

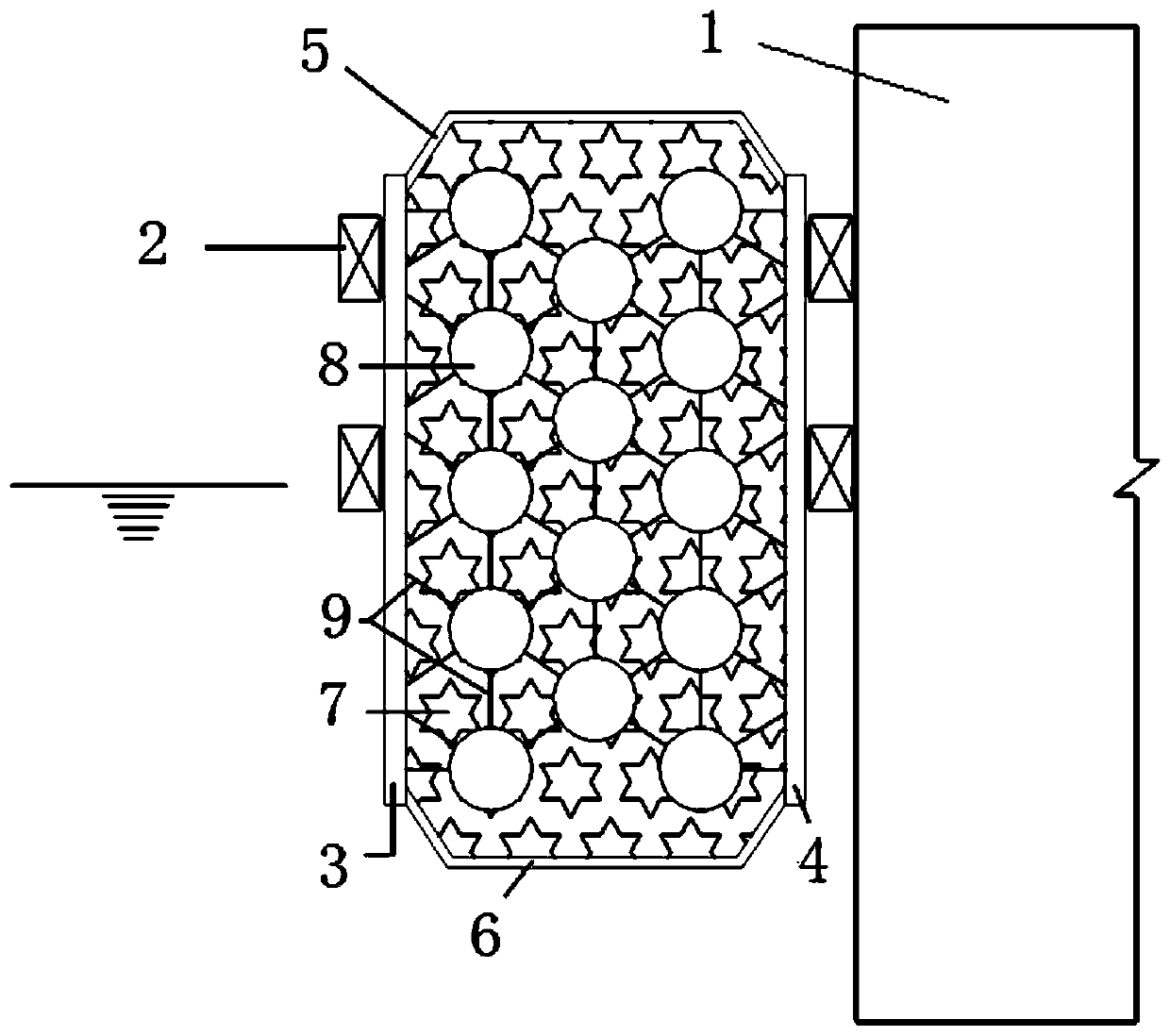

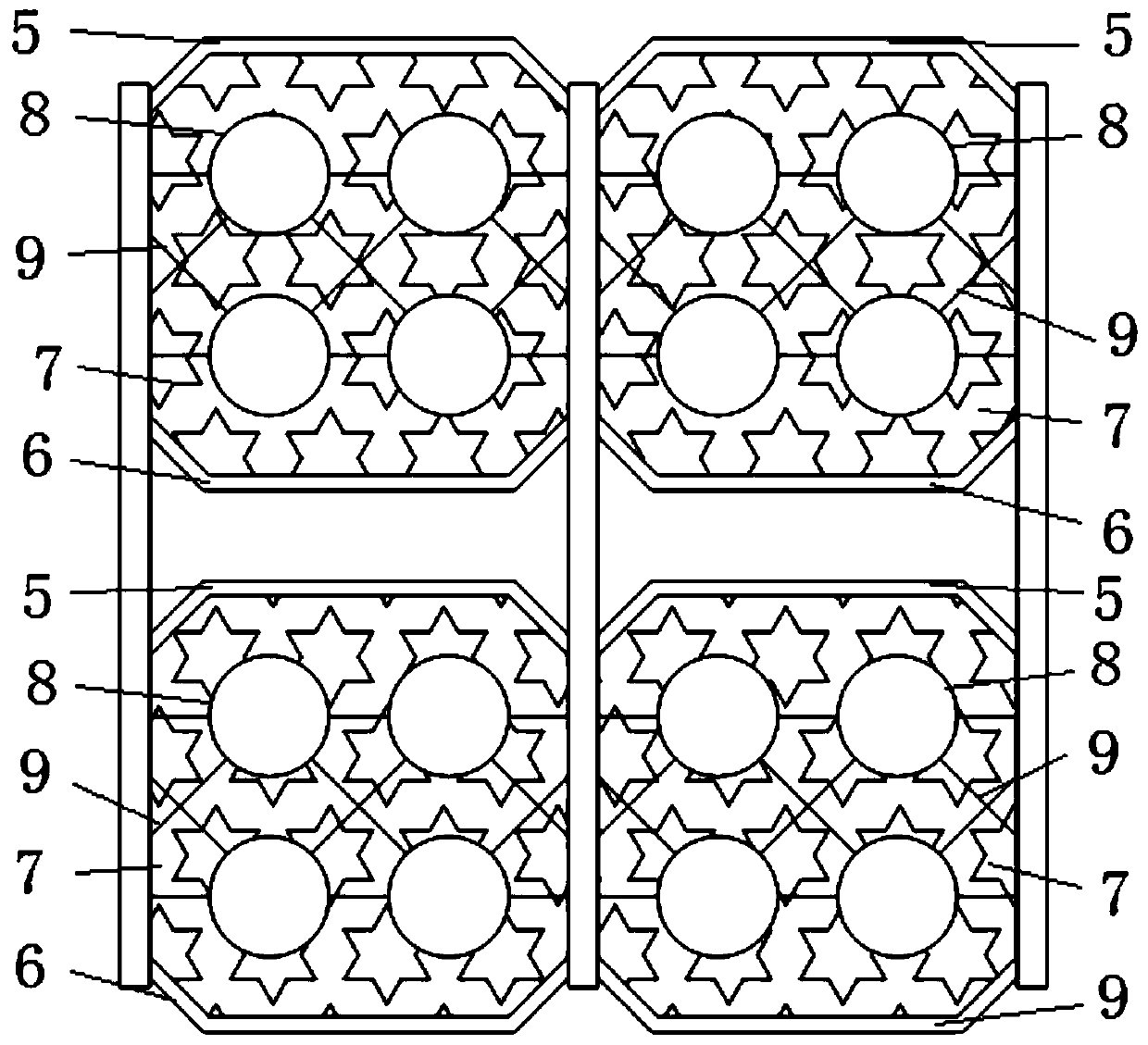

[0027] Such as figure 1 and figure 2 As shown, the anti-ship structure of the attached steel-concrete composite structure is attached to the outer wall of the pier or cap 1 at the level of the water surface, and includes one or more units.

[0028] The unit includes the shell, which is a box-shaped structure made of strain-strengthened UHPC concrete;

[0029] The hollow inner cavity of the shell is provided with a skeleton, and is filled with foam concrete 7;

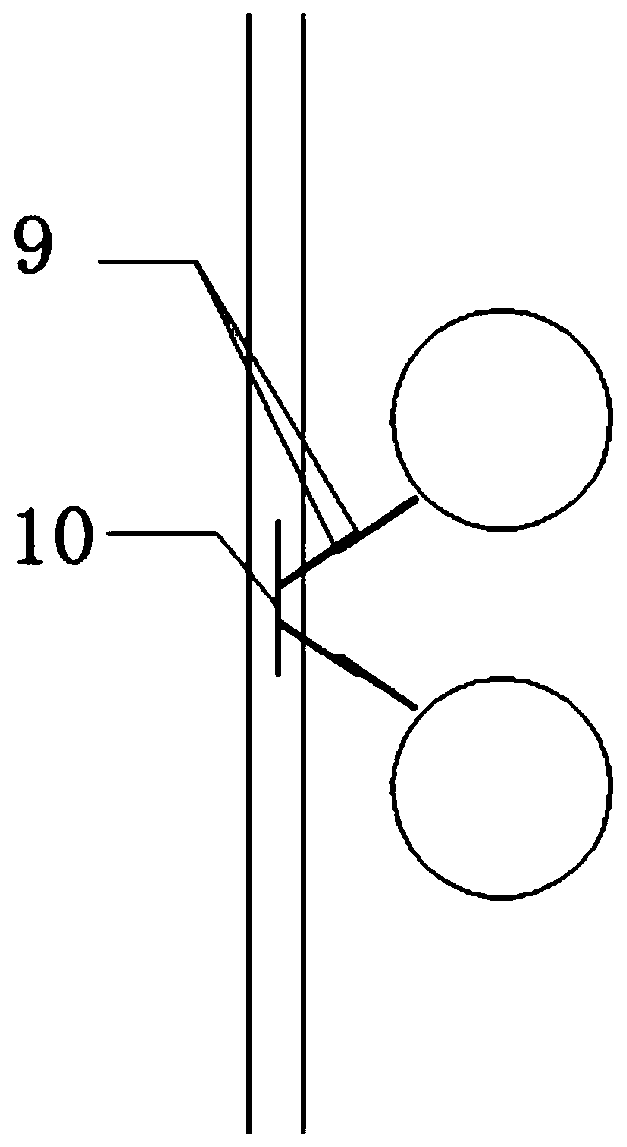

[0030] The skeleton includes several thin steel pipes 8 and several steel lattice structures 9;

[0031] Several thin steel pipes 8 are arranged parallel to each other, and the length direction of each thin steel pipe 8 is parallel to the horizontal direction;

[0032] Every two adjacent thin steel pipes 8 are connected by steel lattice 9 to form a network structure;

[0033] A number of cavities surrounded by a number of shaped steel lattice structures 9 and the inner wall of the shell are all filled with foam con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com