Double bottom element for double bottom

A double-component technology, which is applied in the assembly field of multiple double-bottom components, can solve the disadvantages of dismantling and rebuilding the production system, and achieve the effect of minimizing time and operation cost and flexible production mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

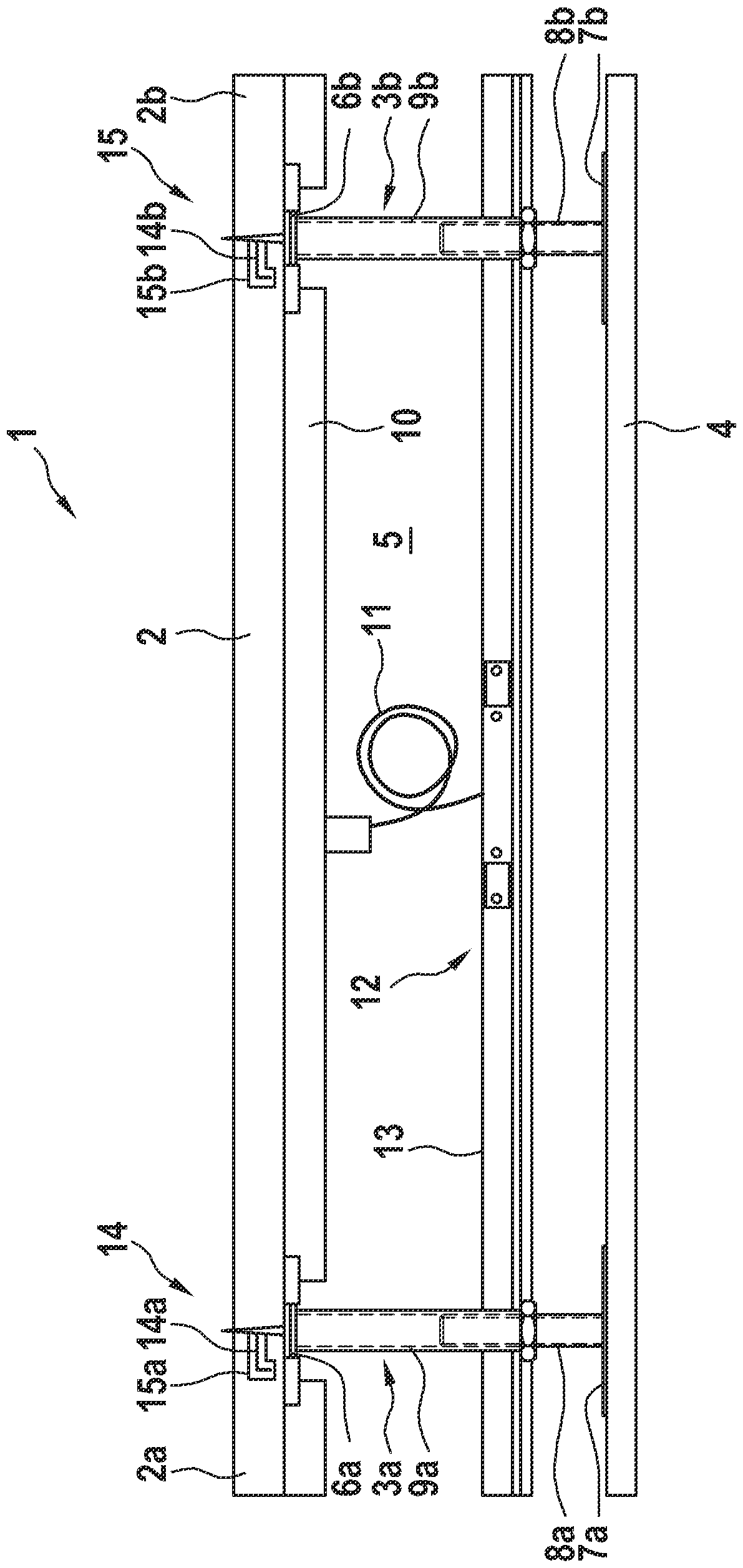

[0046] according to figure 1 , the double bottom element 1 consists of an upper bottom plate 2 which rests at the top corners on a frame element 3 which is designed with brackets 3a, 3b, for example metal brackets, by means of which the bottom plate 2 is supported on a primary bottom, for example concrete 4 above. The base plate 2 is arranged at a distance from the original base 4 by means of the supports 3 a , 3 b , so that a free space 5 (interspace) is formed between the original base 4 and the base plate 2 and delimited by the frame elements 3 . The supports 3 a and 3 b have a top plate 6 a or 6 b for supporting the top corners of the base plate 2 and have a foot plate 7 a or 7 b with which the supports 3 a and 3 b rest on the original base 4 . The brackets 3a, 3b are preferably height-adjustable, for example via threaded rods 8a or 8b on the foot plate 7a or 7b, which are inserted into threaded tubes 9a or 9b on the top plate 6a or 6b.

[0047] according to figure 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com