Super high-rise external facade steel structure horizontal protective platform

A protection platform and facade technology, which is applied in the direction of building structure, construction, and building materials processing, can solve problems such as potential safety hazards and unstable structure of horizontal protection platforms, so as to avoid overturning, improve connection stability, and stabilize sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

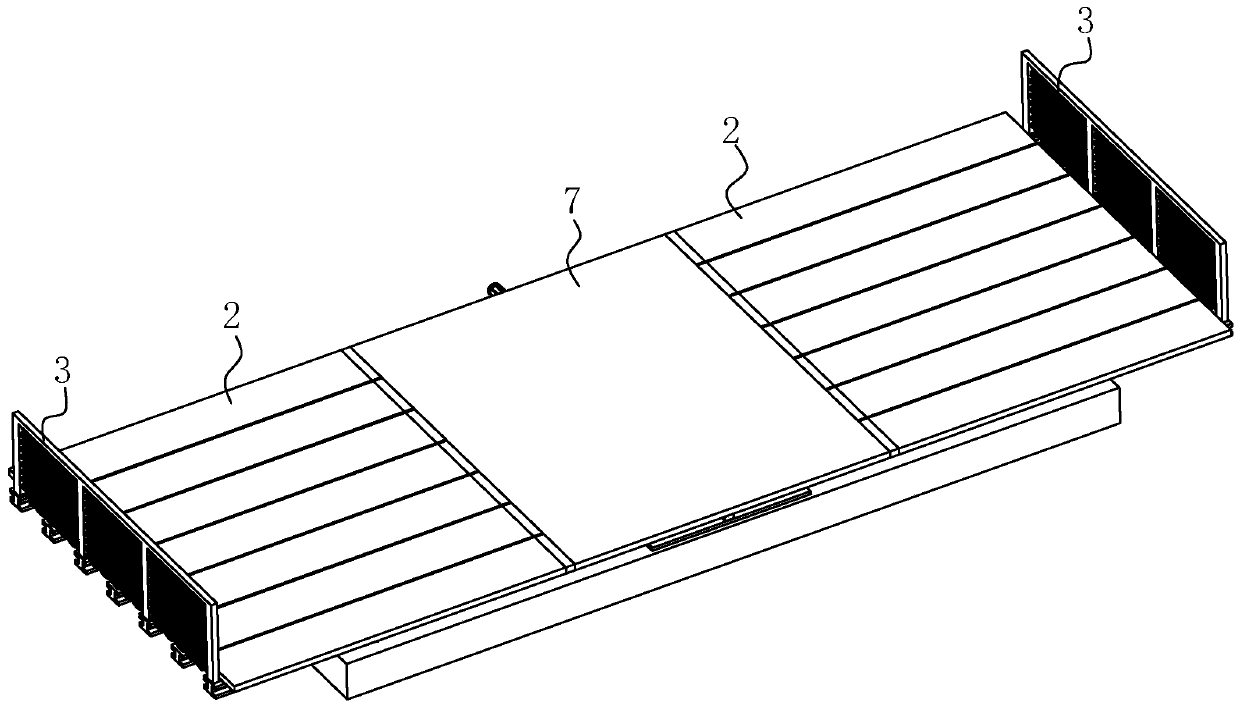

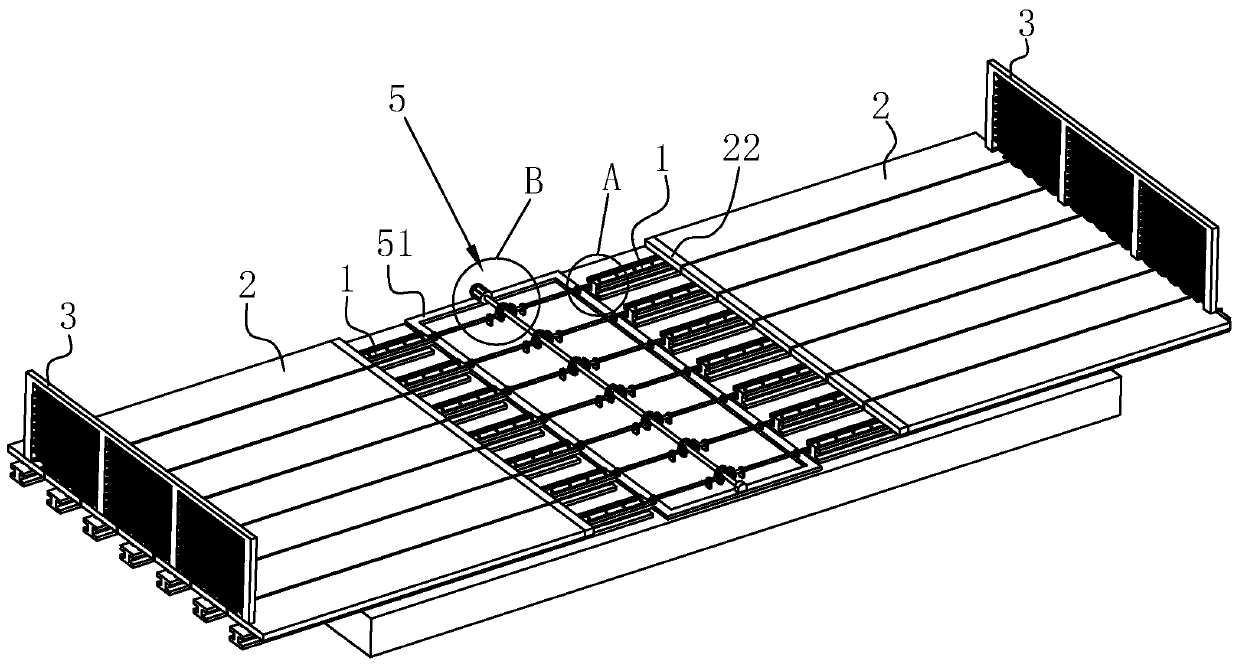

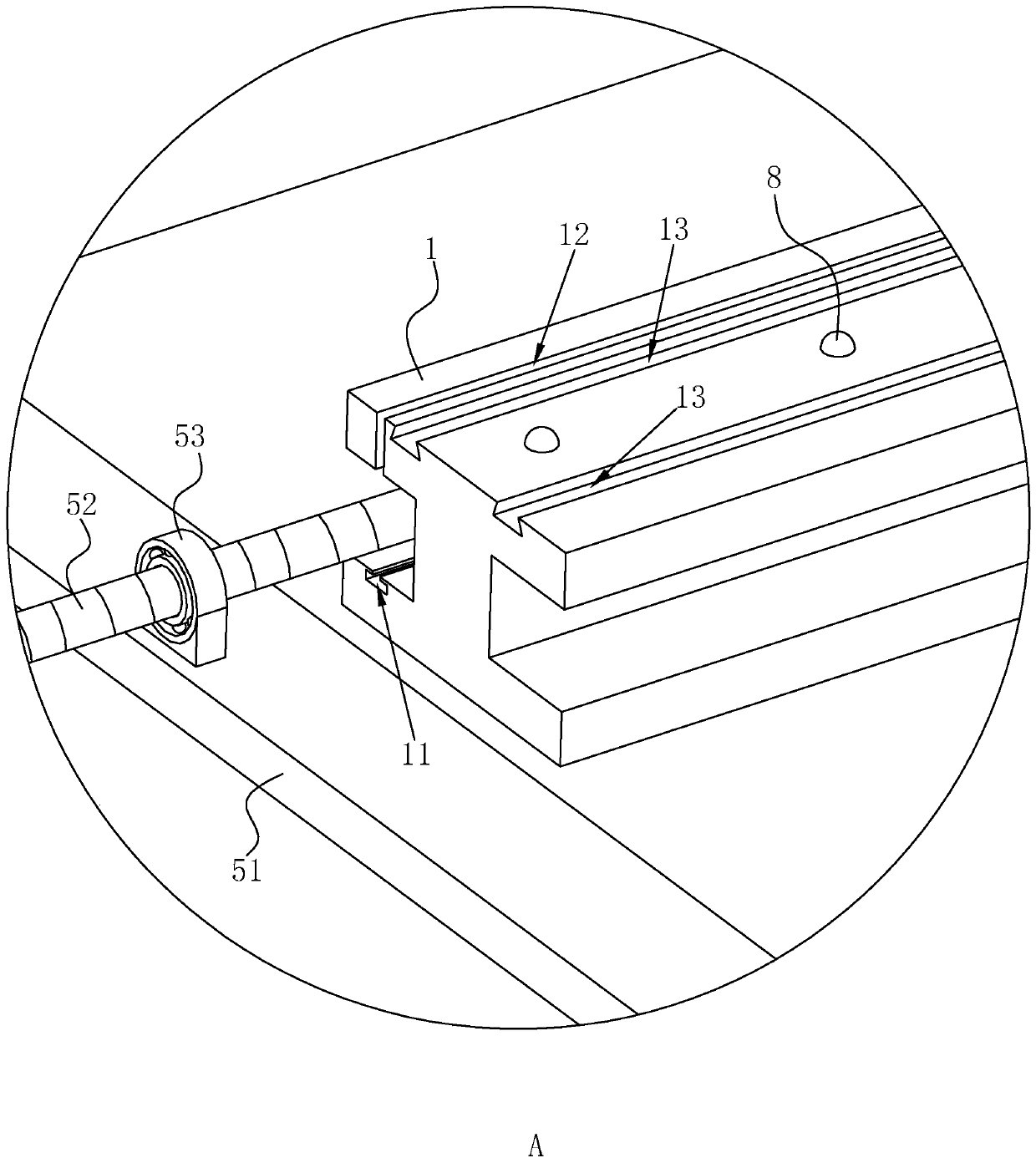

[0034] Such as figure 1 , 2 As shown in the figure, a horizontal protection platform of super high-rise facade steel structure includes I-shaped steel 1, U-shaped steel bar, angle steel, steel plate 2 and protective railing 3. The I-shaped steel 1 passes through the U-shaped steel bar pre-buried on the floor. Fix it through the angle steel, the I-beam 1 cantilever out of the floor, the steel plate 2 is placed on the section of the I-beam 1 outside the floor, and the end of the steel plate 2 is welded with a protective railing 3; it is worth noting that in order to To express the content of the present invention well, in the accompanying drawings, U-shaped steel bars and angle steel bars are not drawn, but in the actual installation process, workers should install angle steel bars and pre-embedded U-shaped steel bars according to sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com