a ball valve

A ball valve and valve seat technology, applied in the field of ball valves with ash removal function, can solve the problems of ball valve leakage, scratches, damaged valve balls, etc., and achieve the effects of ensuring air tightness, reducing economic losses, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

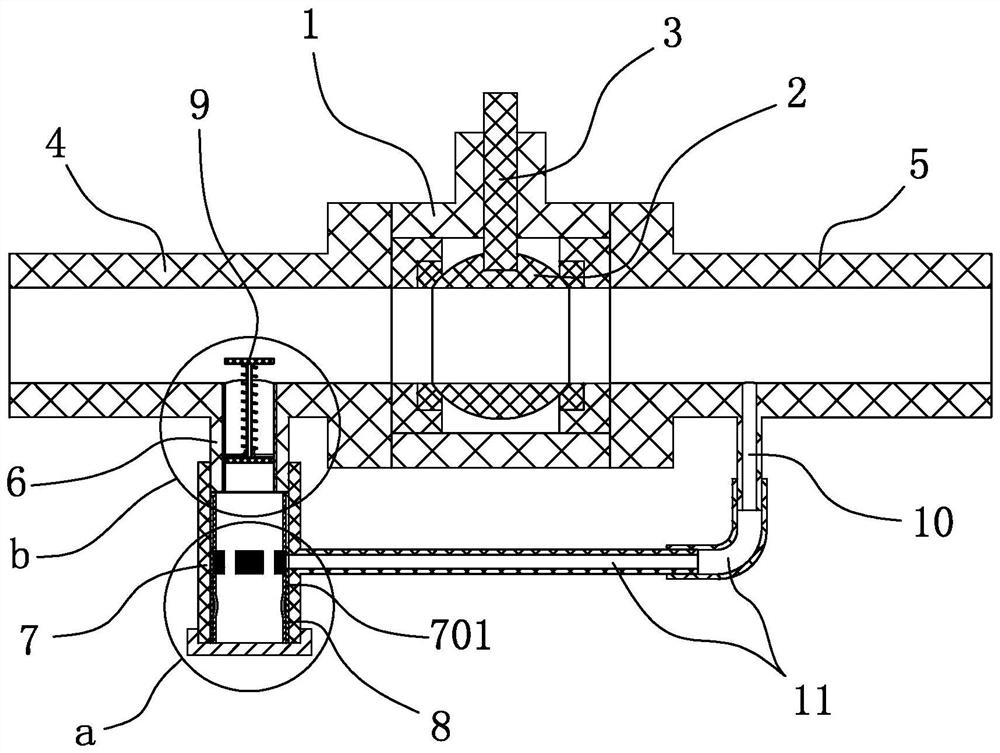

[0029] Embodiment one: see Figure 1 to Figure 8

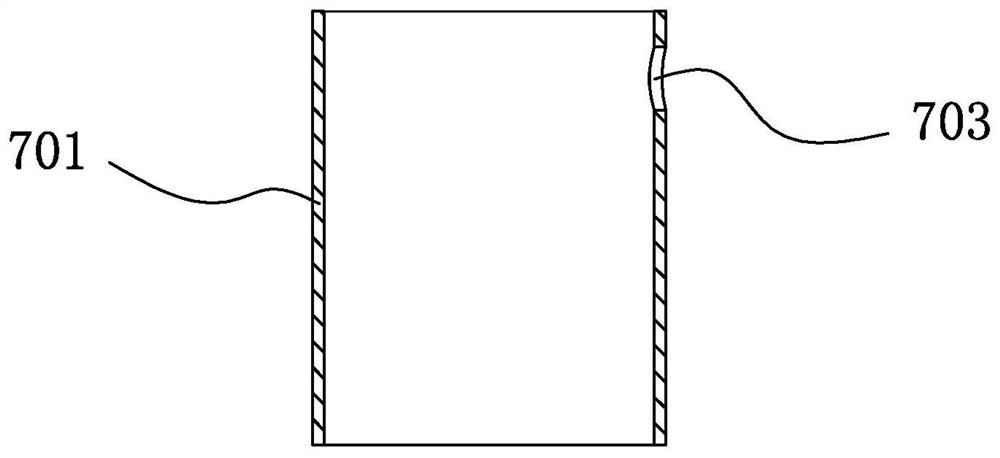

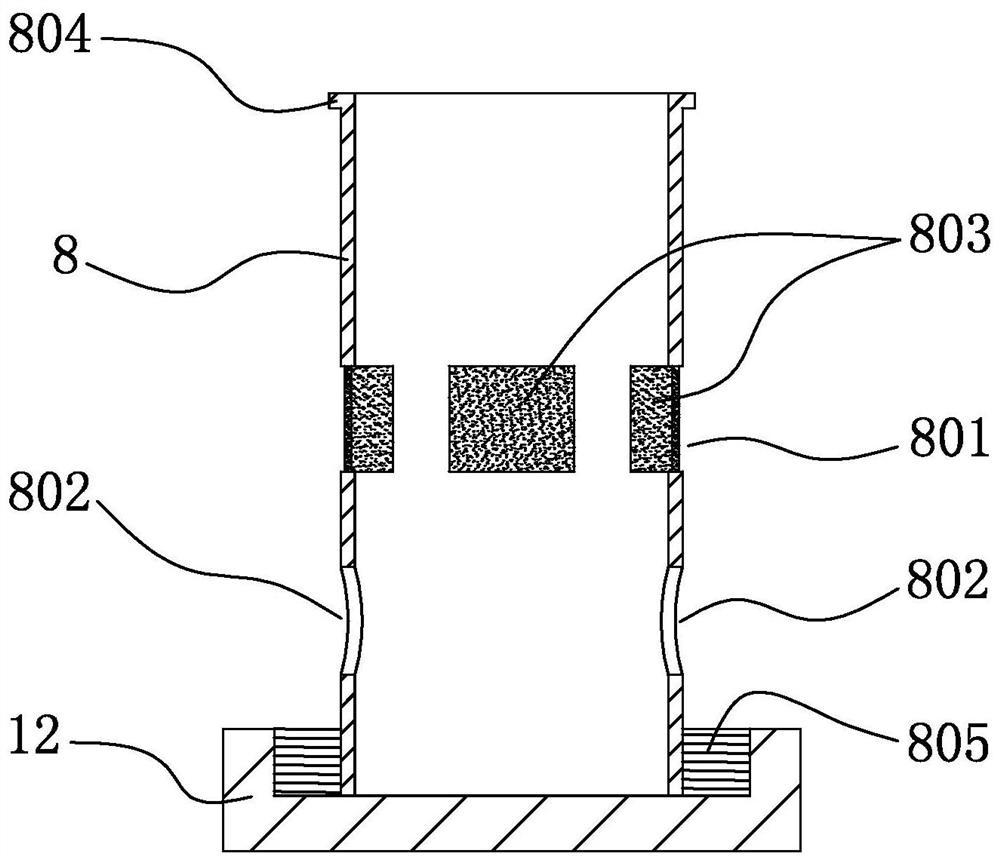

[0030] A ball valve, comprising a valve seat 1, a valve ball 2 arranged in the valve seat 1, a valve stem 3 used to drive the valve ball 2, an intake pipe 4 arranged on one side of the valve seat 1, and an air intake pipe 4 arranged on the other side of the valve seat 1 One side of the air outlet connecting pipe 5, the outer wall of the air inlet connecting pipe 4 is provided with an ash falling pipe 6, the ash falling pipe 6 is erected on the lower side of the air inlet connecting pipe 4, and the upper end of the ash falling pipe 6 is connected with the air inlet connecting pipe 4 And connected, the central axis of the ash-falling pipe 6 is perpendicular to the central axis of the intake pipe 4 , and a first sliding pipe 601 is embedded in the tube hole of the ash-falling pipe 6 .

[0031] The lower end of the ash fall pipe 6 is provided with an ash storage pipe 7, the upper section of the ash storage pipe 7 is sleeved on th...

Embodiment 2

[0043] Embodiment two: see Figure 9 to Figure 12

[0044] A ball valve, comprising a valve seat 1, a valve ball 2 arranged in the valve seat 1, a valve stem 3 used to drive the valve ball 2, an intake pipe 4 arranged on one side of the valve seat 1, and an air intake pipe 4 arranged on the other side of the valve seat 1 One side of the air outlet connecting pipe 5, the outer wall of the air inlet connecting pipe 4 is provided with an ash falling pipe 6, the ash falling pipe 6 is erected on the lower side of the air inlet connecting pipe 4, and the upper end of the ash falling pipe 6 is connected with the air inlet connecting pipe 4 And connected, the central axis of the ash-falling pipe 6 is perpendicular to the central axis of the intake pipe 4 , and a first sliding pipe 601 is embedded in the tube hole of the ash-falling pipe 6 .

[0045] The lower end of the ash fall pipe 6 is provided with an ash storage pipe 7, the upper section of the ash storage pipe 7 is sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com