Improved structure of diverting valve

An improved structure and diverter valve technology, applied in the valve shell structure, valve details, multi-way valve, etc., can solve the problems of time-consuming, laborious, manpower, suspension of machines and professional equipment, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

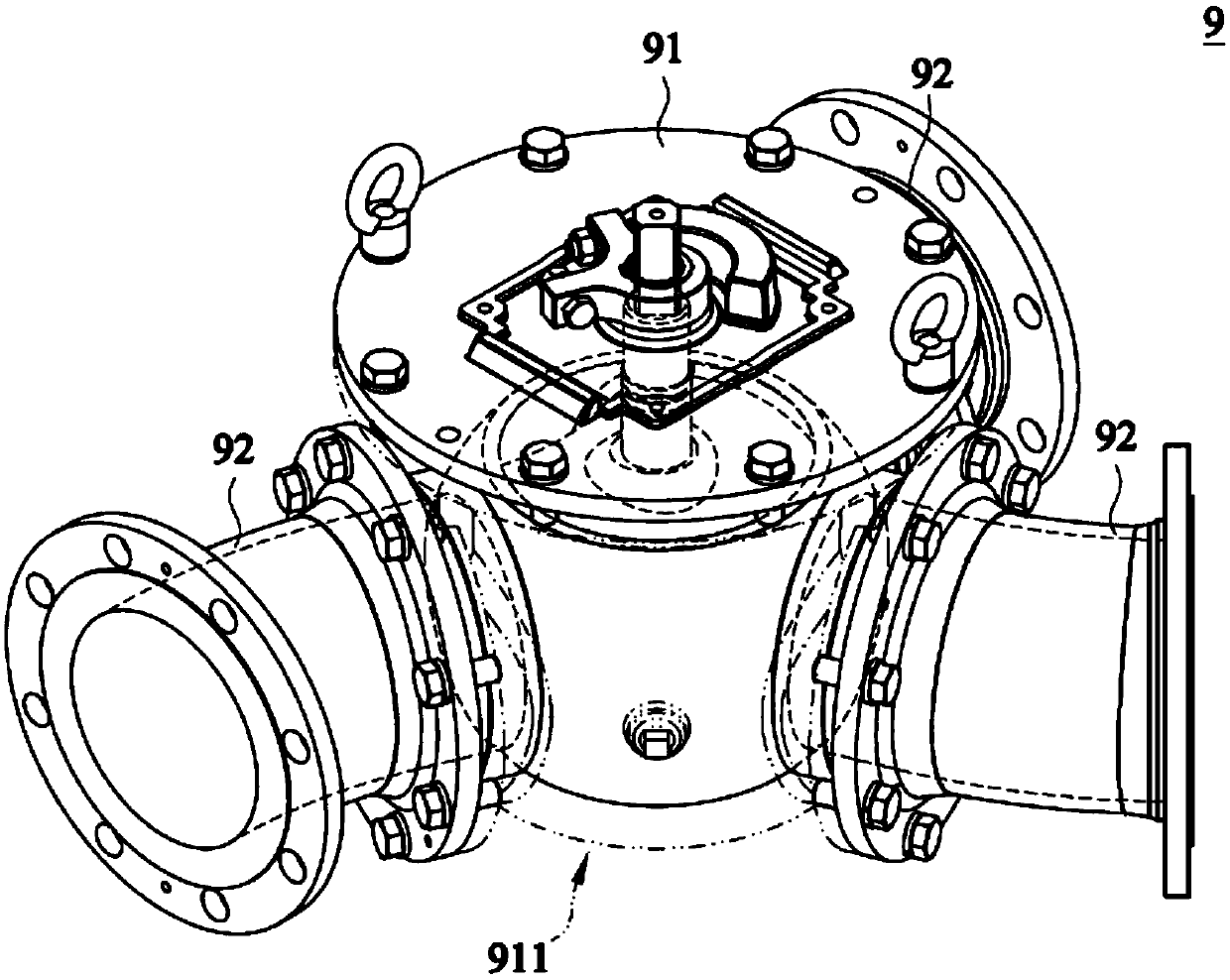

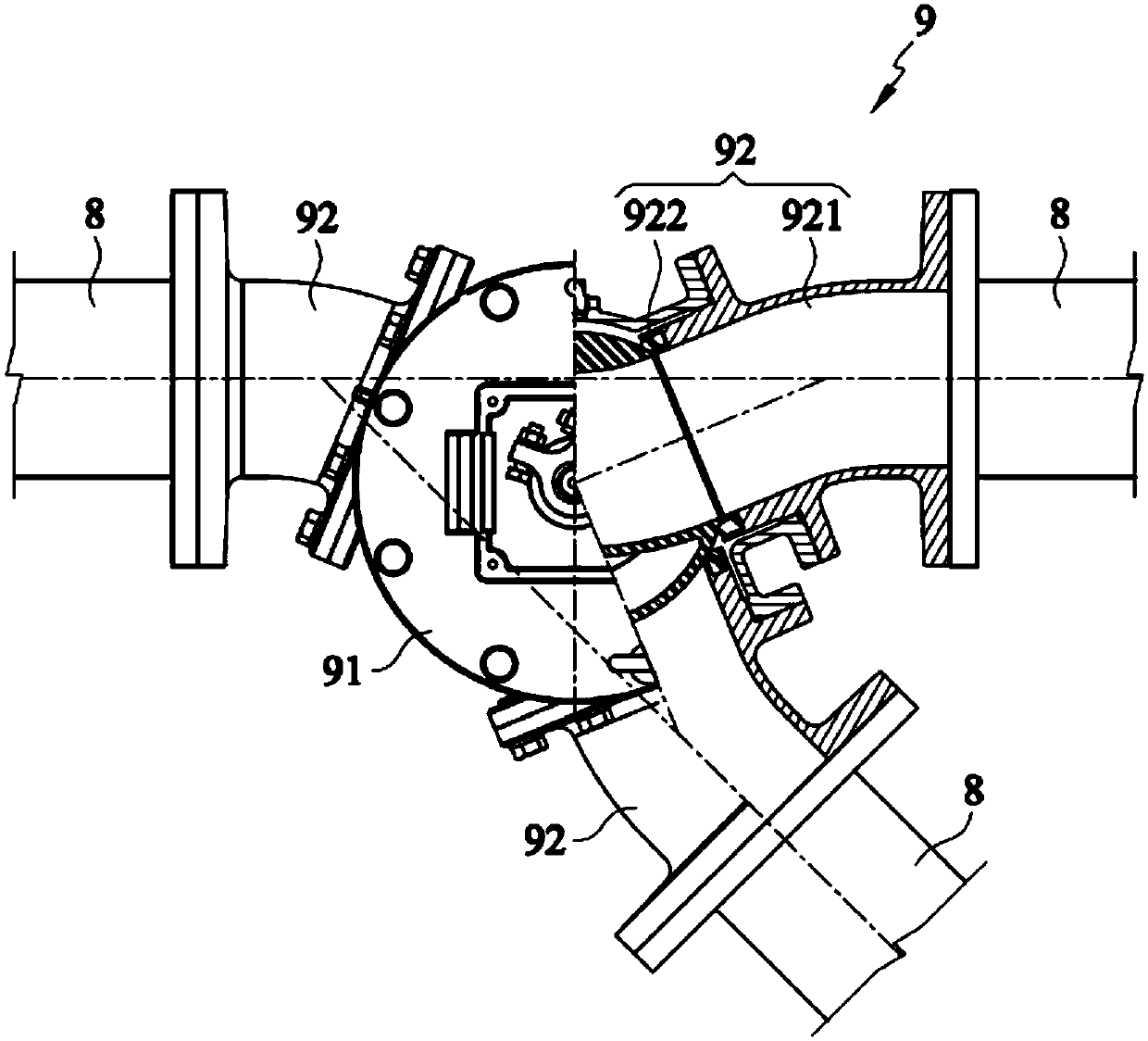

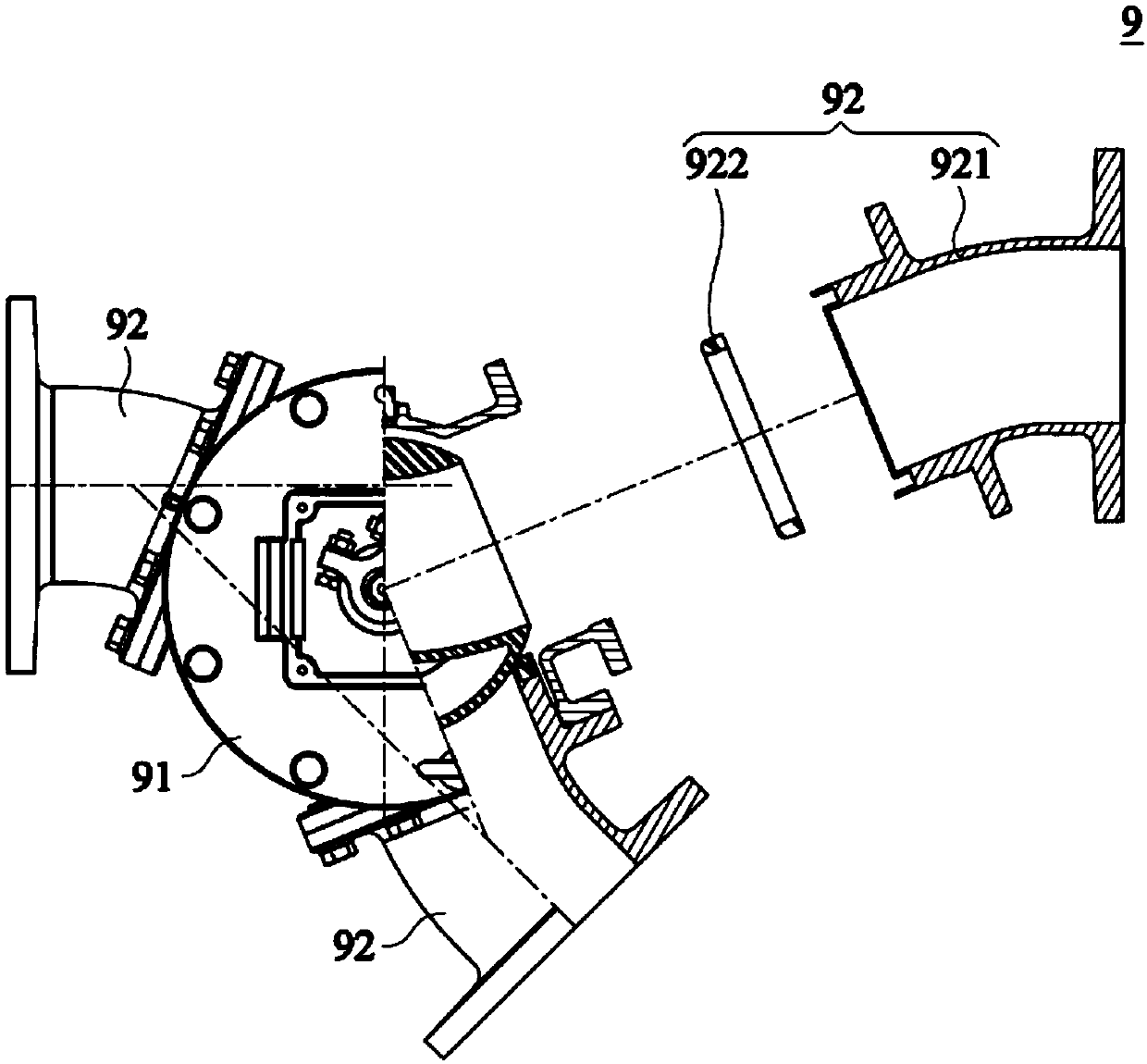

[0030] Please also refer to Figure 4 to Figure 6 ,in Figure 4 It is a top view of a preferred embodiment of the present invention, Figure 5 It is one of the disassembly schematic diagrams of a preferred embodiment of the present invention, Figure 6 It is the second disassembly schematic diagram of a preferred embodiment of the present invention.

[0031] Such as Figure 4 to Figure 6 As shown, the improved structure 1 of the directional valve of the preferred embodiment of the present invention includes a directional valve body 2 and a plurality of flow passages 3, wherein the number of flow passages 3 is three in this embodiment, and are respectively connected to the group Set to the diverter valve body 2, as detailed below.

[0032] Figure 4 to Figure 6 The diverter valve body 2 shown includes an inner chamber 21 and a plurality of passages 22, the number of the plurality of passages 22 corresponds to the plurality of flow passages 3, that is, three, and the plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com