Downstream ash blockage prevention system and ash blockage prevention method adopting smoke circulation

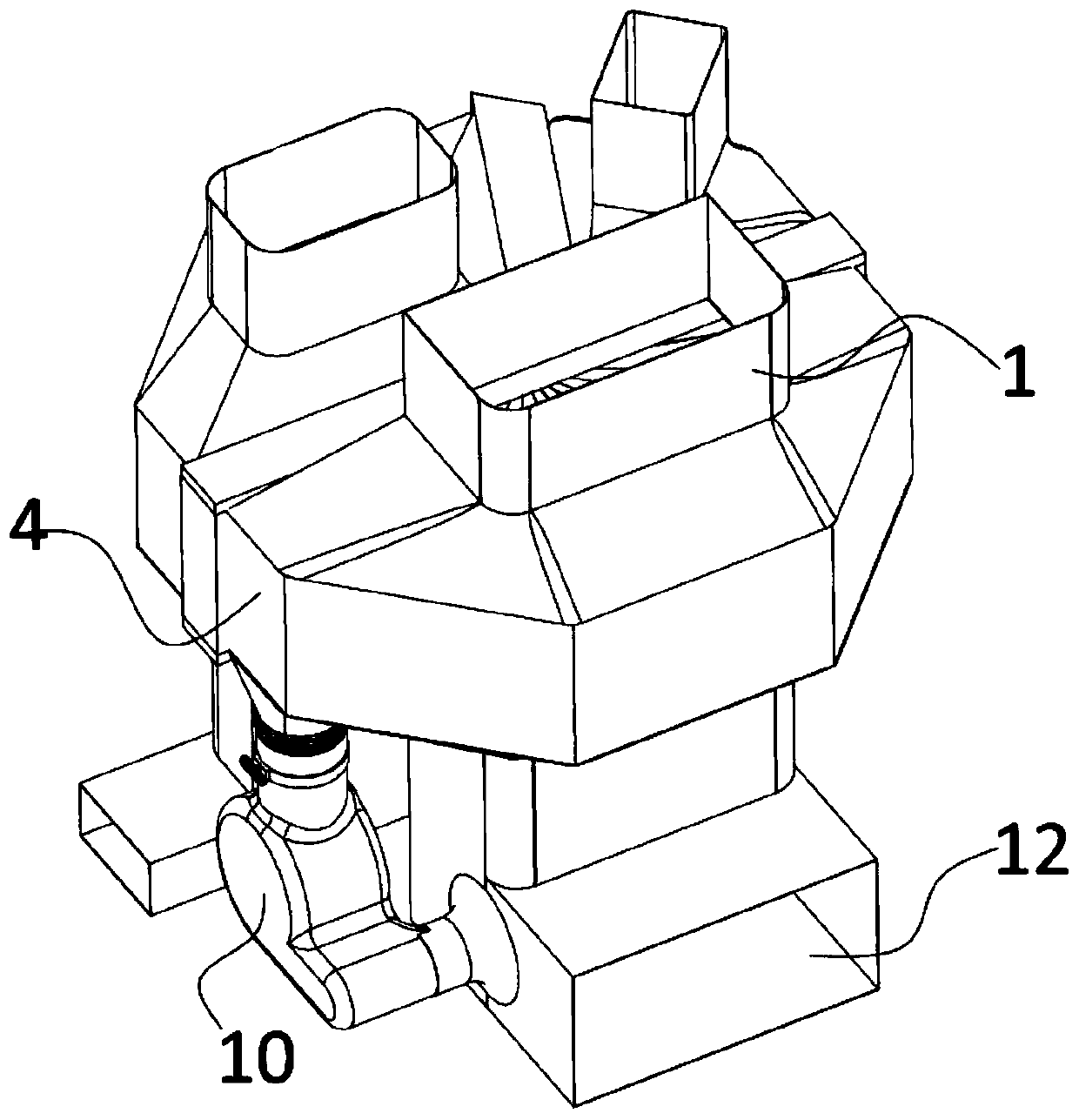

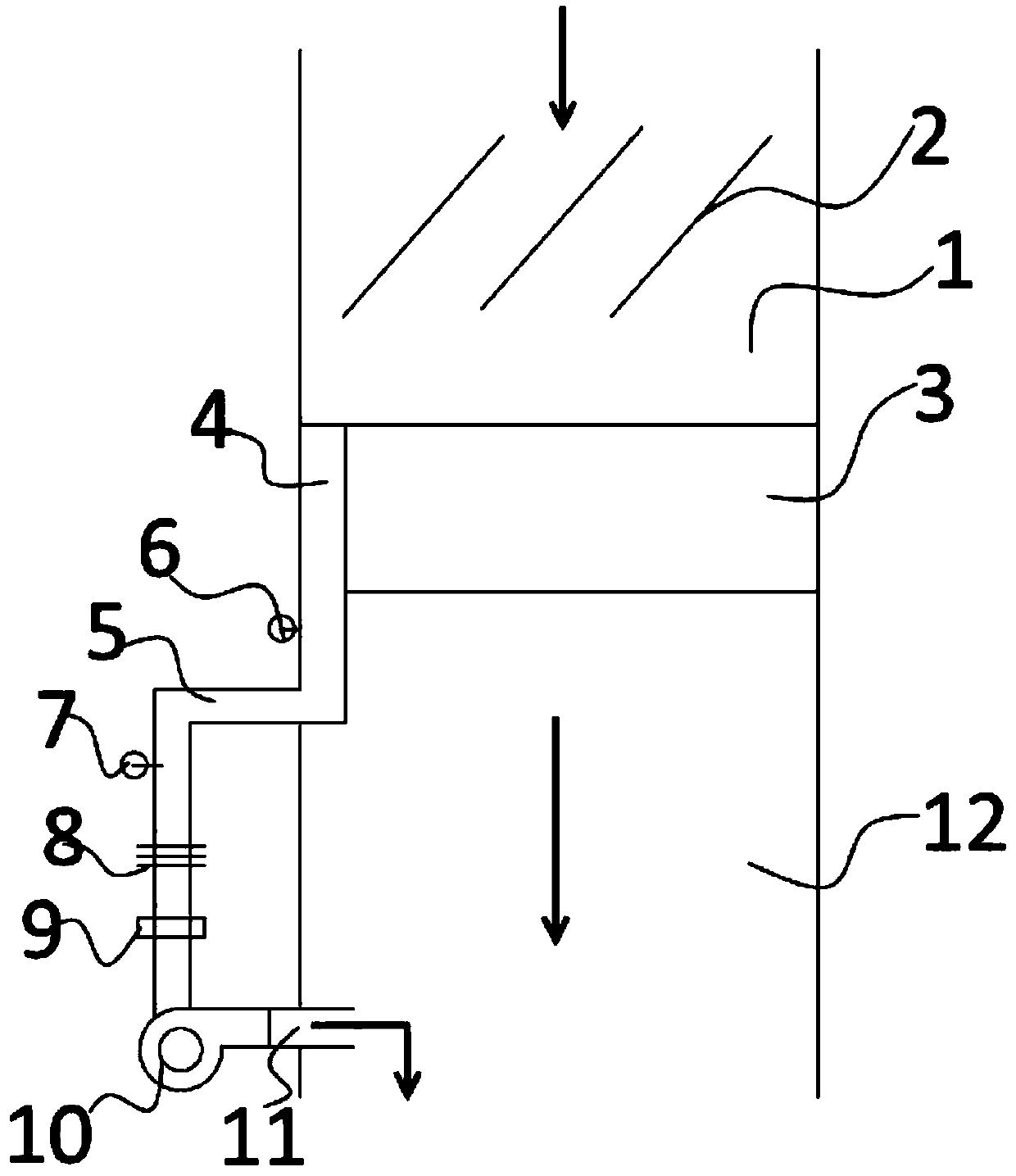

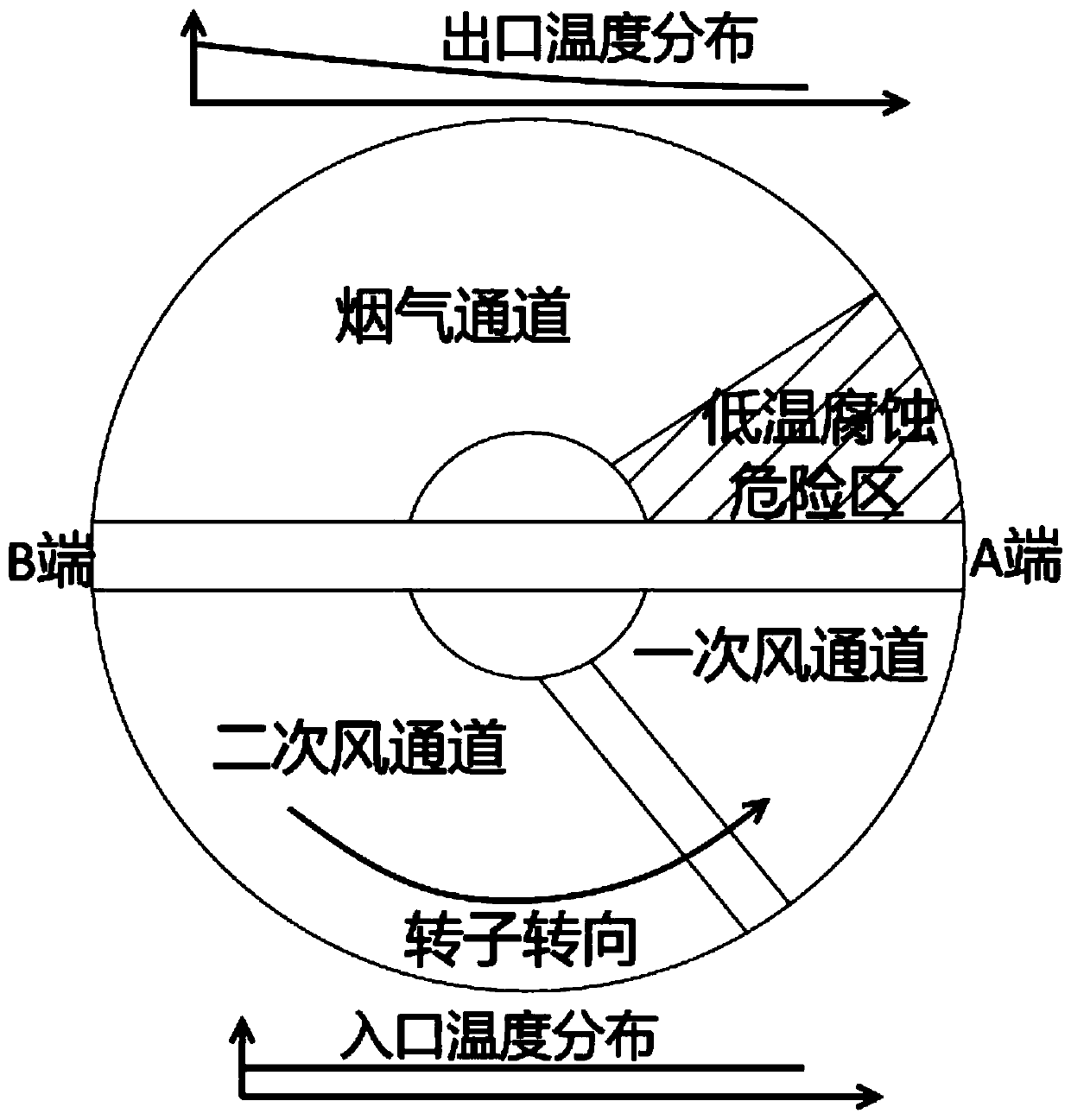

A technology of flue gas circulation and flue gas flow, which is applied in the field of downstream anti-clogging ash devices and flue gas circulation downstream anti-clogging ash air preheaters, which can solve the problem of ash blocking, hard lumps, and ash blocking in the air preheater To achieve the effect of eliminating ash plugging and eliminating low-temperature corrosion dangerous areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]After the research and analysis of the applicant, the reason for this problem (units are forced to apply for shutdown or cause non-stop accidents often occur, which seriously affects the safety and normal production of power generation) is that the denitrification system is put into operation. The dust blocking of the air preheater caused by transportation has seriously threatened the safe operation of the unit. The phenomenon of corrosion and dust blocking of the air preheater of coal-fired boilers in China is becoming more and more serious, and its performance has two remarkable characteristics. The more and more units have the problem of dust blocking of the air preheater, the second is that the degree of dust blocking is becoming more and more serious. The designed air preheater flue gas side resistance is usually around 1000Pa, and the actual resistance is as high as about 3000Pa, and some are even as high as More than 4000Pa, when the heat storage element has just b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com