Test device and method for detecting porosity of particles in Hull-Shore sheet

A test device, porosity technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of untestable density and uniformity of samples, and achieve the goal of solving the problem of test failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

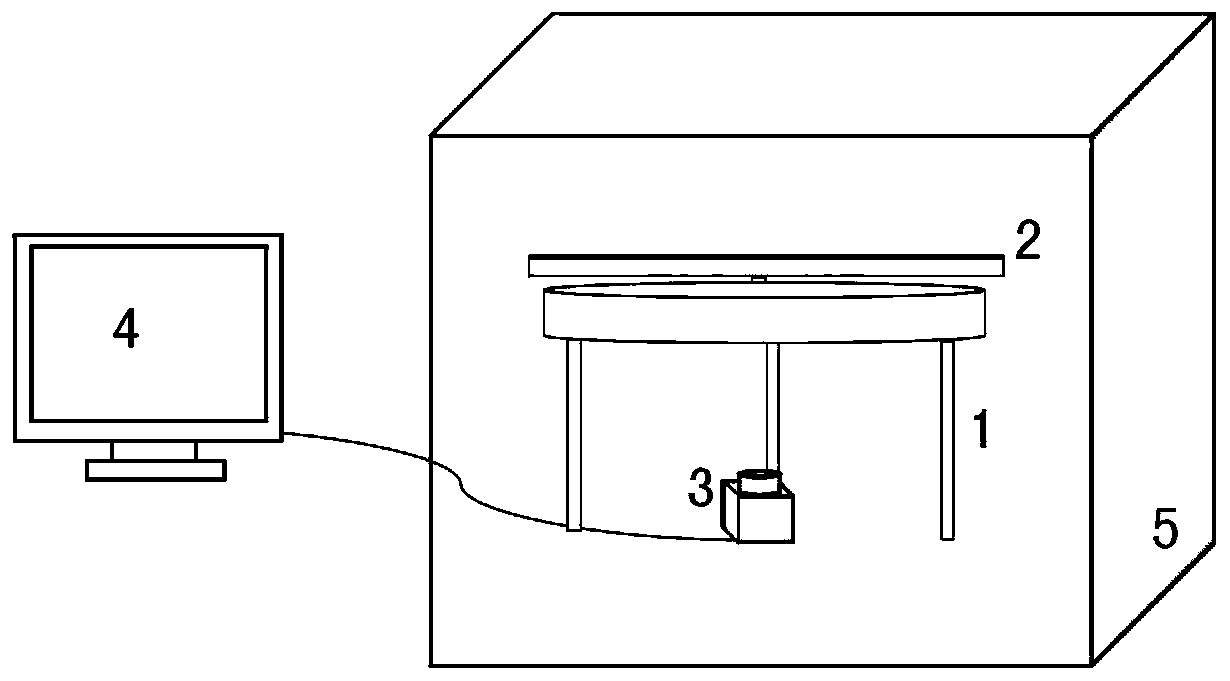

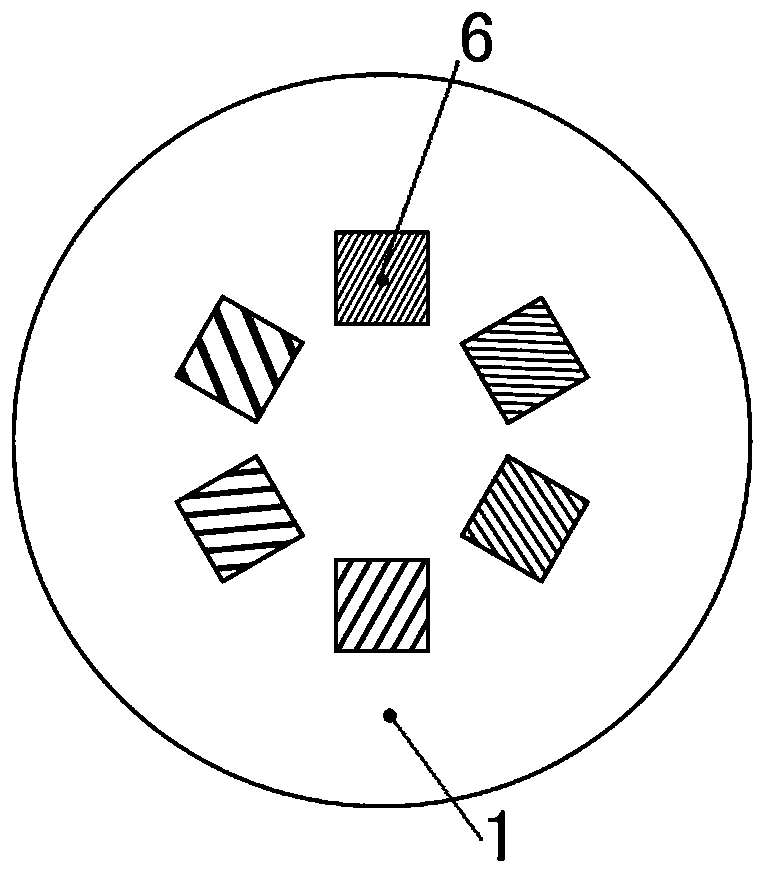

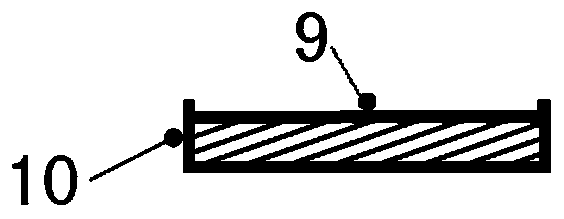

[0041]In this embodiment, on the top panel of the Hull-Shore particle slide rack 1, six (N=6) mounting slots are evenly distributed in the circumferential direction, and six Hull-Shore thin plates can be assembled. The particle sample slide 6, the shadowless lamp 2 is the only light source of the whole system, and it is placed 3 cm above the Hull-Shore Sheng particle slide holder 1, and the circumference of the six Hull-Shore sheet particle sample slides 6 is The diameter is smaller than the diameter of the area irradiated by the light emitted by the upper shadowless lamp 2, so as to ensure that the light emitted by the upper shadowless lamp 2 can only pass through the range of the glass slide containing particles. The CCD camera 3 is placed directly under the Hull-Shoresh particle slide holder 1 and is connected to the data processing system 4 through a data line for collecting and processing images. All the above-mentioned devices, except the data processing system 4, are pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com