Acoustic emission source positioning method suitable for three-dimensional structure

An acoustic emission source and three-dimensional structure technology, which is applied in the direction of material analysis, positioning, and processing detection response signals using acoustic emission technology, can solve the problems of not being able to obtain three-dimensional structural characteristics in advance, achieve good application prospects, and ensure safety , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

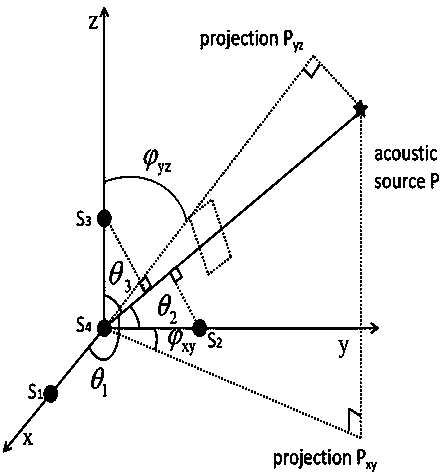

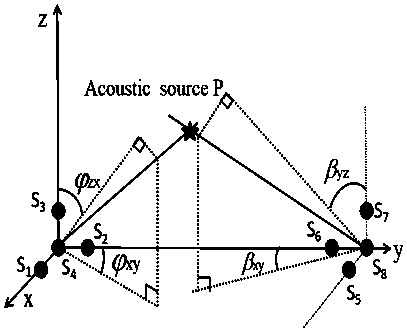

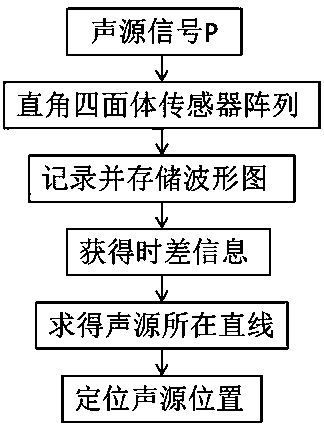

[0068] Sound source localization in three-dimensional structures is a difficult task. The invention proposes a new technology, which is suitable for fast acoustic emission source localization in three-dimensional structures. Compared with the traditional positioning method, the characteristics of the constituent materials do not need to be known in advance, not only suitable for isotropic materials, but also suitable for anisotropic materials; only 8 ultrasonic sensors are needed, which can greatly reduce the continuous The cost of monitoring the structure; does not require any iterative algorithm, effectively improving the positioning accuracy and speed. The invention proposes a new method for sound source localization in acoustic emission detection, and ensures the safety of the structure by timely detecting damage and potential threats, and has good application prospects in the fields of aerospace navigation, civil engineering, large and small machinery, and the like.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com