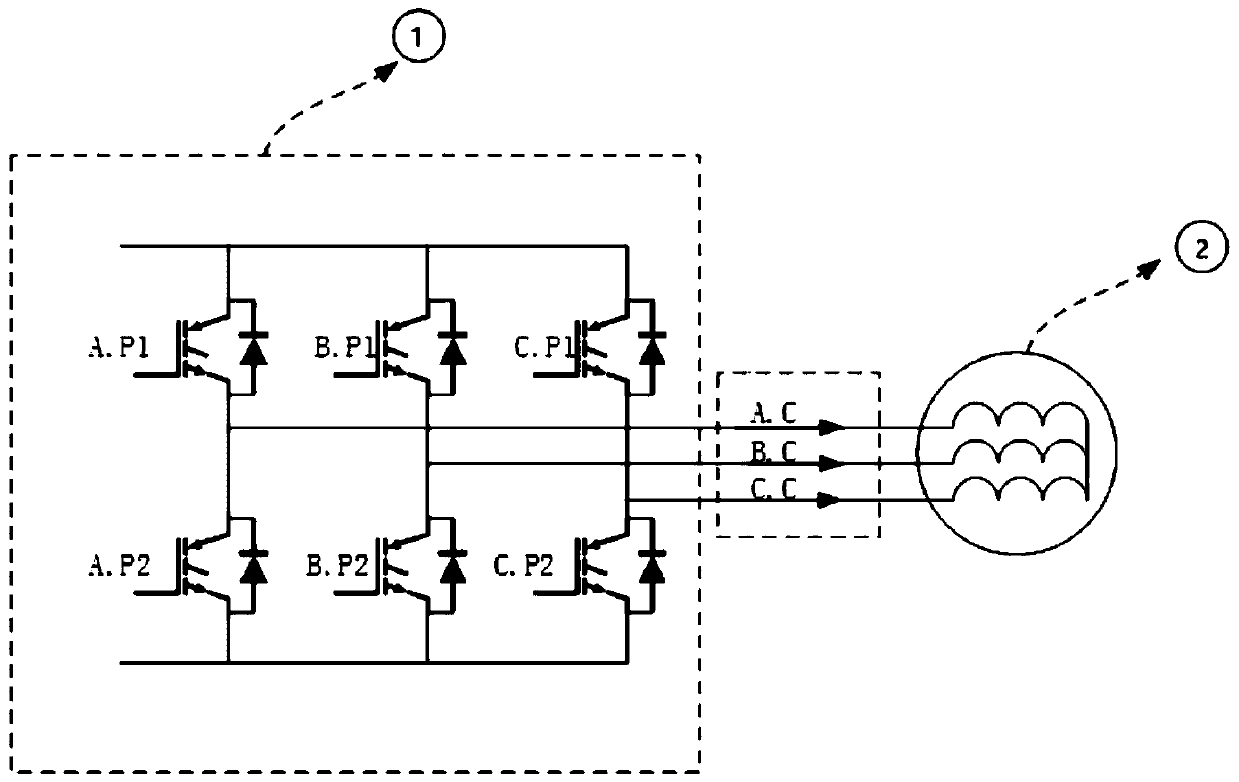

Real-time junction temperature calculation method of servo driver power module

A servo driver and power module technology, applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems of lack of reliability and complex structure, and achieve the effect of real-time calculation, simple calculation and convenient real-time calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

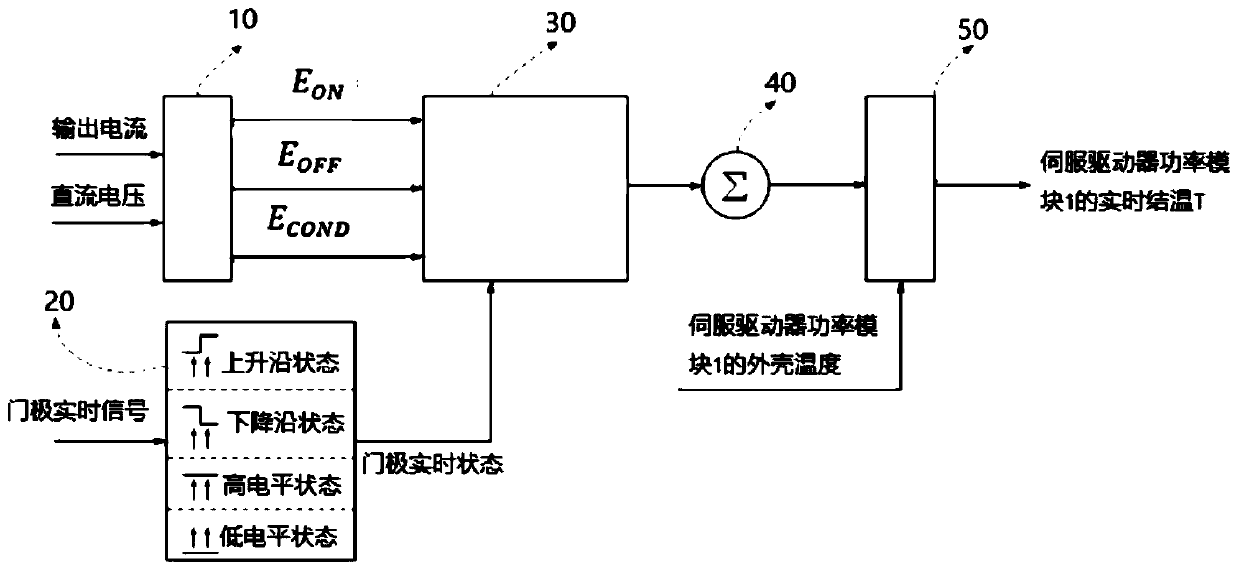

Method used

Image

Examples

Embodiment Construction

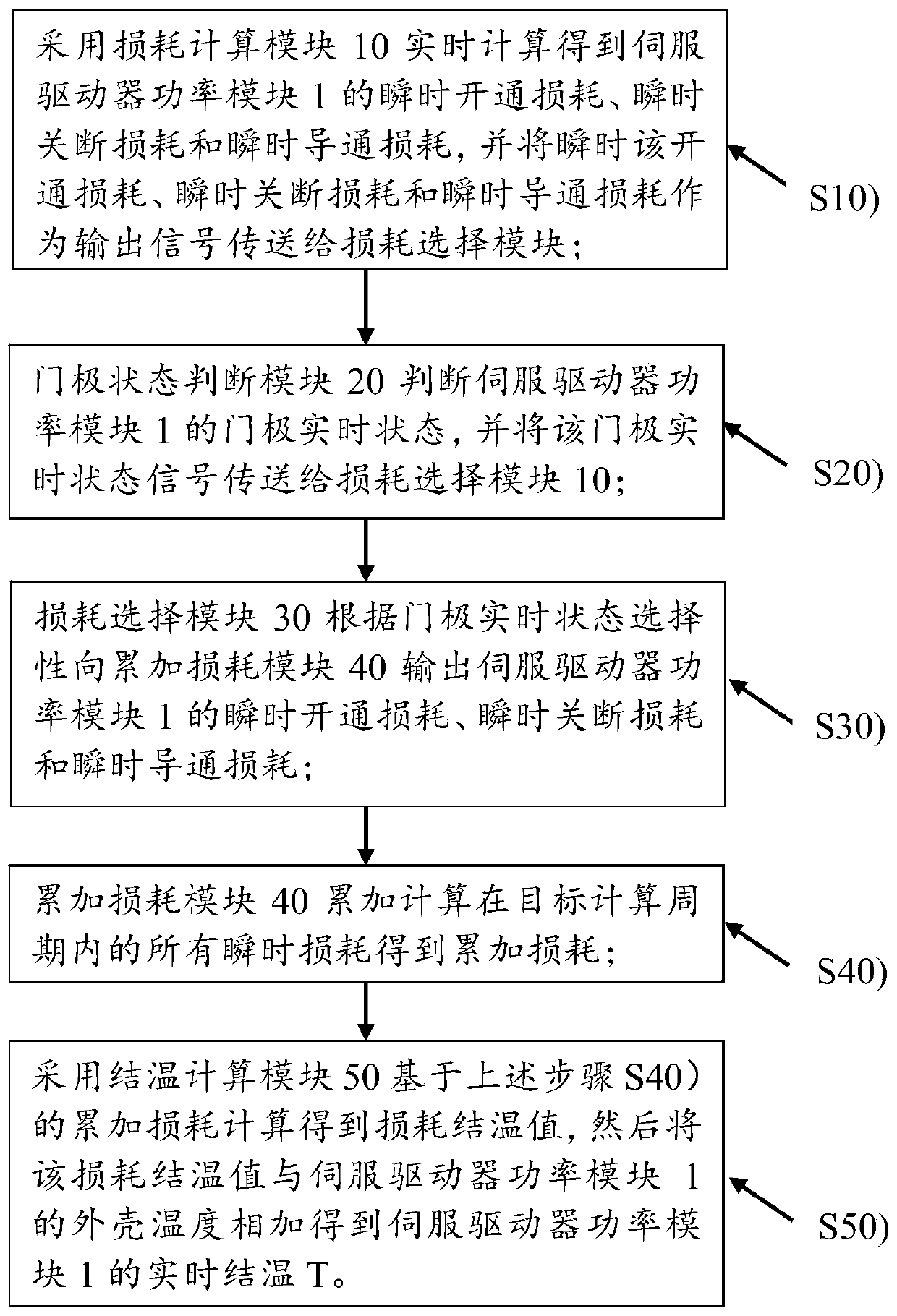

[0041] The embodiment of the present invention discloses a real-time junction temperature calculation method of a servo drive power module, and its operation steps include the following:

[0042] S10), using the loss calculation module to calculate in real time the instantaneous turn-on loss, instantaneous turn-off loss and instantaneous conduction loss of the power module of the servo drive, and transmit the instantaneous turn-on loss, instantaneous turn-off loss and instantaneous conduction loss as output signals to loss selection module; S20), the gate state judging module judges the gate real-time state of the power module of the servo drive, and transmits the gate real-time state signal to the loss selection module; S30), the loss selection module selects the gate according to the real-time state of the gate The accumulated loss module outputs the instantaneous turn-on loss, instantaneous turn-off loss and instantaneous conduction loss of the power module of the servo driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com