Stick puller for pork shashlik

A meat strip and chain conveyor technology is applied in the field of meat strip string pulling and brazing machine, which can solve the problems of increasing labor cost, large workload, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

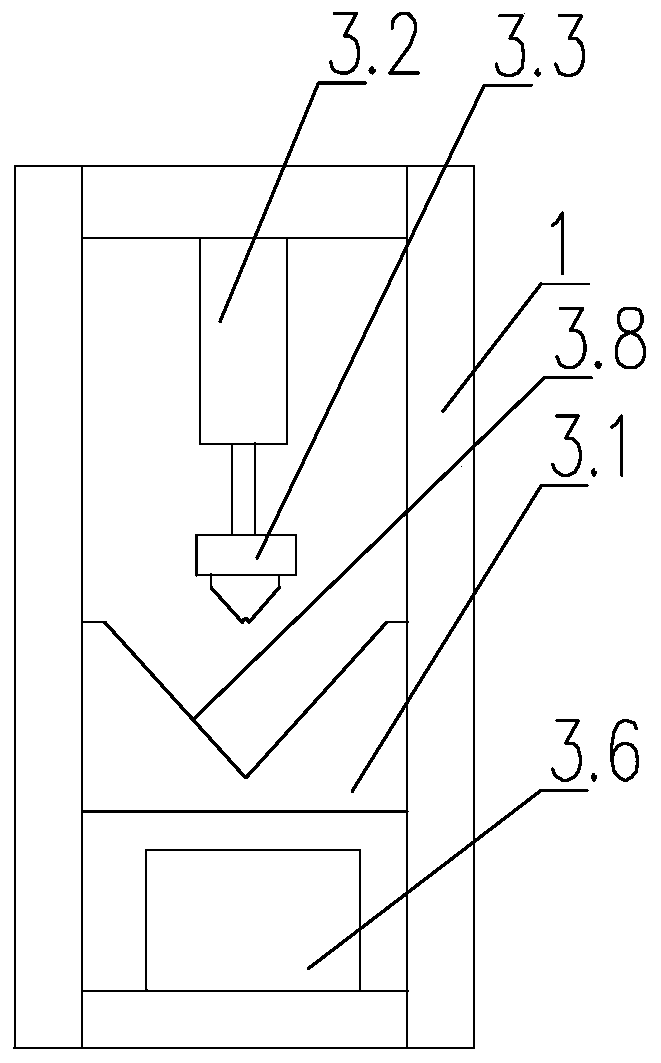

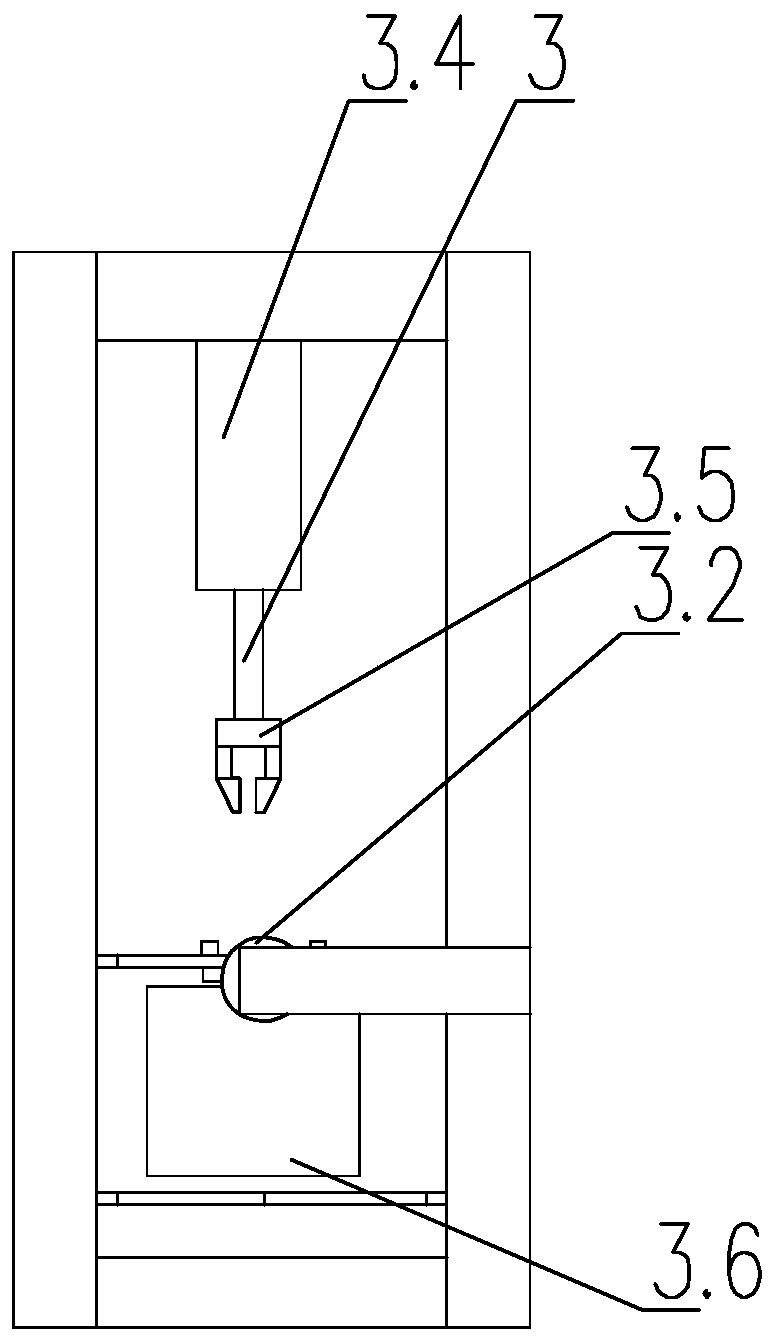

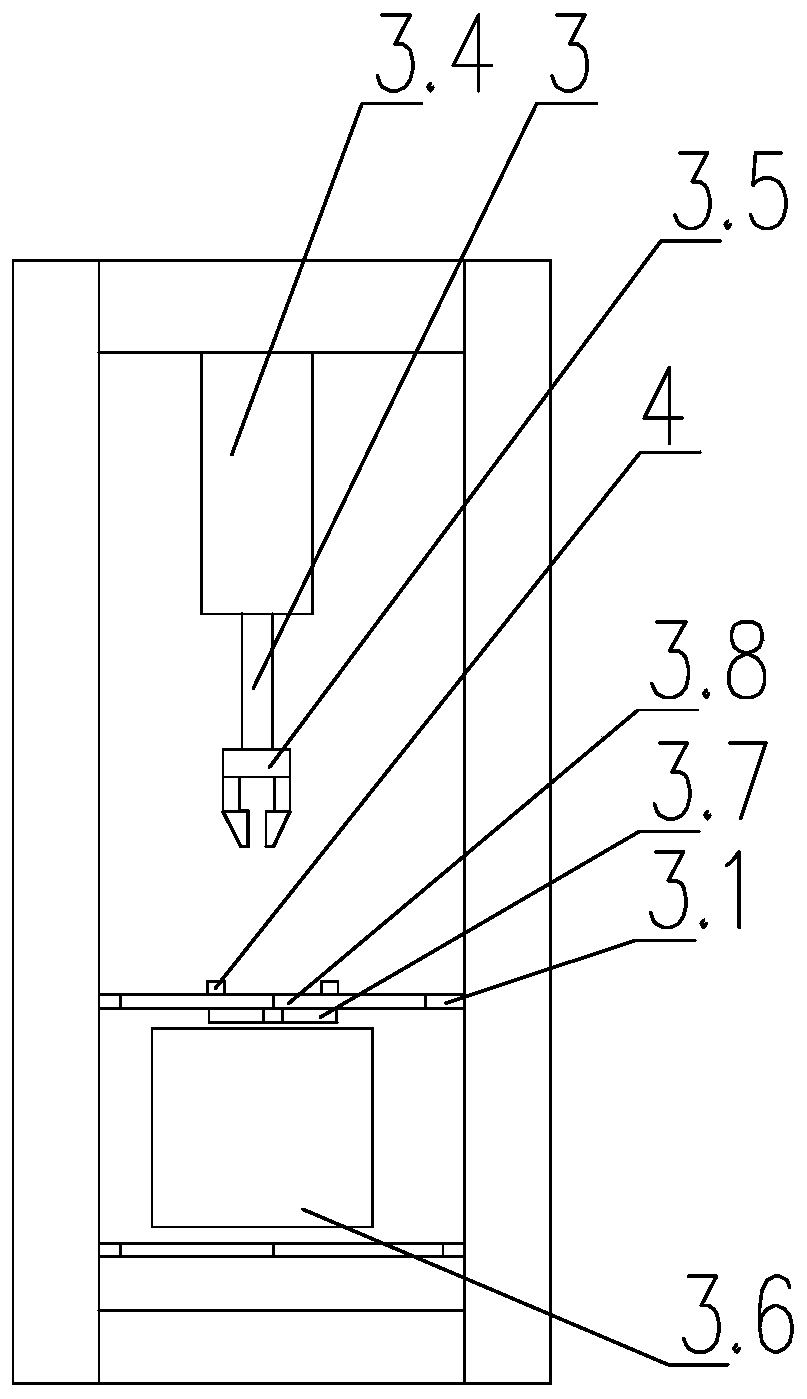

[0035] Such as figure 1 , figure 2 , image 3 , Figure 7 The shown brazing machine for stringing meat strings includes a frame 1 and a brazing mechanism 3 arranged on the frame 1;

[0036] The brazing mechanism 3 includes two vertically arranged frame plates 3.1, a horizontal oil cylinder 3.4, a lifting oil cylinder 3.2, an electric gripper 3.5, an upper stopper 3.3 and a lower stopper 3.7;

[0037] The frame 1 is vertically fixed with two frame plates 3.1 arranged parallel to each other, and the tops of the two frame plates 3.1 are provided with upward V-shaped grooves 3.8 with mutually symmetrical openings; A horizontal oil cylinder 3.4 is horizontally arranged on the frame 1, and an electric gripper 3.5 is fixed on the top of the piston rod of the horizontal oil cylinder 3.4, and the clamping center of the electric gripper 3.5 is on the same horizontal straight line as the groove bottoms of the two V-shaped grooves 3.8 ; The electric gripper 3.5 used in this embodimen...

Embodiment 2

[0044] This embodiment includes all the structures of Embodiment 1, and also includes an infrared through-radiation switch 4 and a controller 5. The infrared through-radiation switch 4 is fixedly arranged on the outer surface of the frame plate 3.1 near the horizontal oil cylinder 3.4, and the infrared through-radiation switch 4 The irradiation line intersects the center line of the brazing channel;

[0045] Such as Figure 8 As shown, the signal output terminal of the infrared shooting switch 4 is connected to the signal input terminal of the controller 5, and the signal output terminal of the controller 5 is respectively connected to the signal input terminals of the electric gripper 3.5, the lifting cylinder 3.2 and the horizontal cylinder 3.4 .

[0046] working principle:

[0047] According to the working principle of embodiment 1, when placed on the bottom of the two V-shaped grooves 3.8, since the two ends of the iron brazing protrude from the relative outer sides of t...

Embodiment 3

[0050] Such as Figure 4 — Figure 7 As shown, the present embodiment includes all the structures of Embodiment 1, and also includes the conveying mechanism 2 provided on the frame 1 at the side end of the frame plate 3.1. The conveying mechanism 2 includes two parallel and symmetrically arranged chain conveyors 2.3, and the chain The conveying direction of the conveyor 2.3 is perpendicular to the axial direction of the horizontal oil cylinder 3.4, and a meat string conveying channel is formed between the two chain conveyors 2.3;

[0051] The two chain conveyors 2.3 are set in one-to-one correspondence with the two frame plates 3.1, and the two chain conveyors 2.3 are respectively arranged on the opposite sides of the two frame plates 3.1, and the discharge ends of the chain conveyors 2.3 are placed in V-shaped grooves 3.8 above the notch.

[0052] The conveying mechanism 2 also includes a drive motor 2.1 and a drive shaft 2.2; the drive motor 2.1 is fixed on the frame 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com