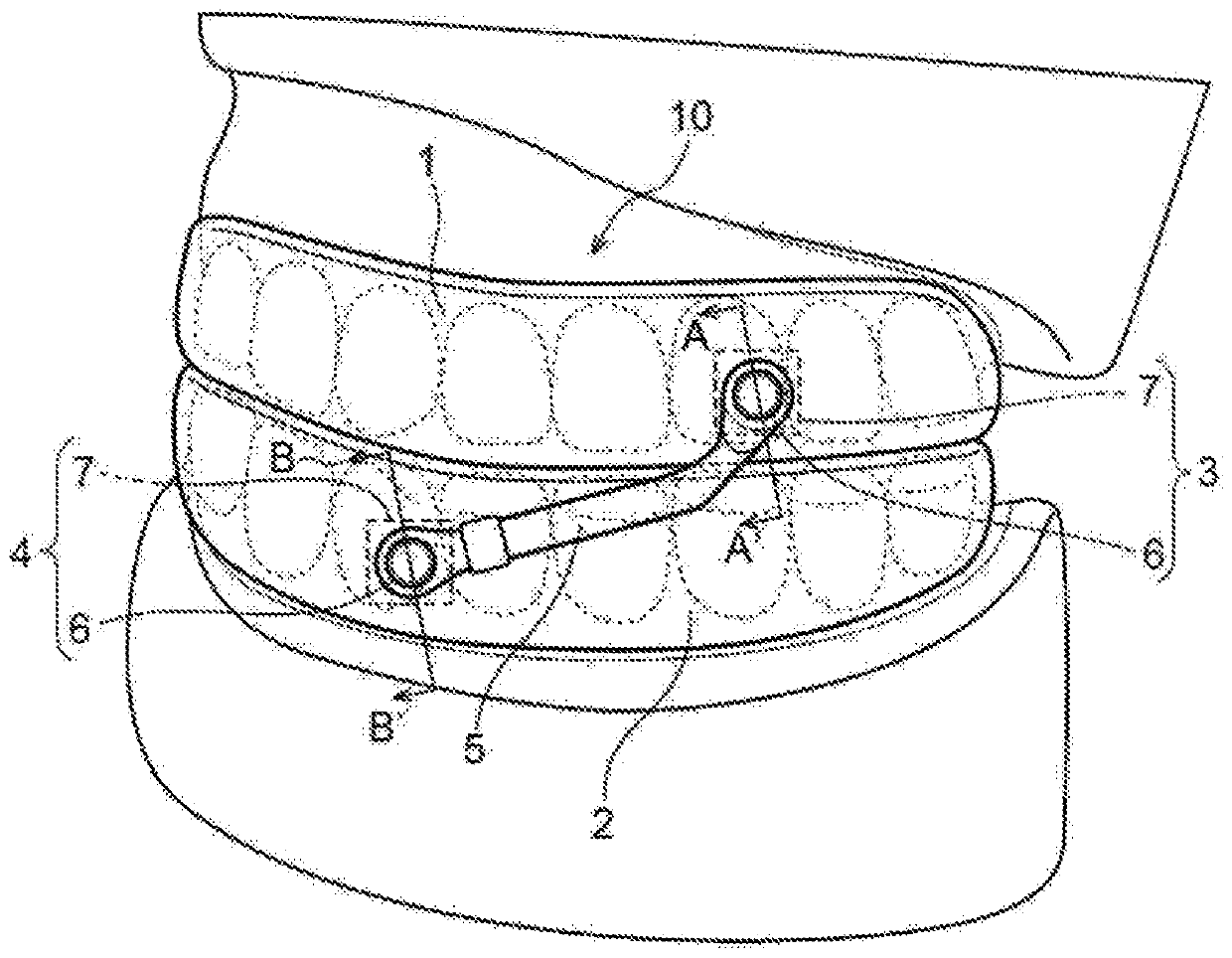

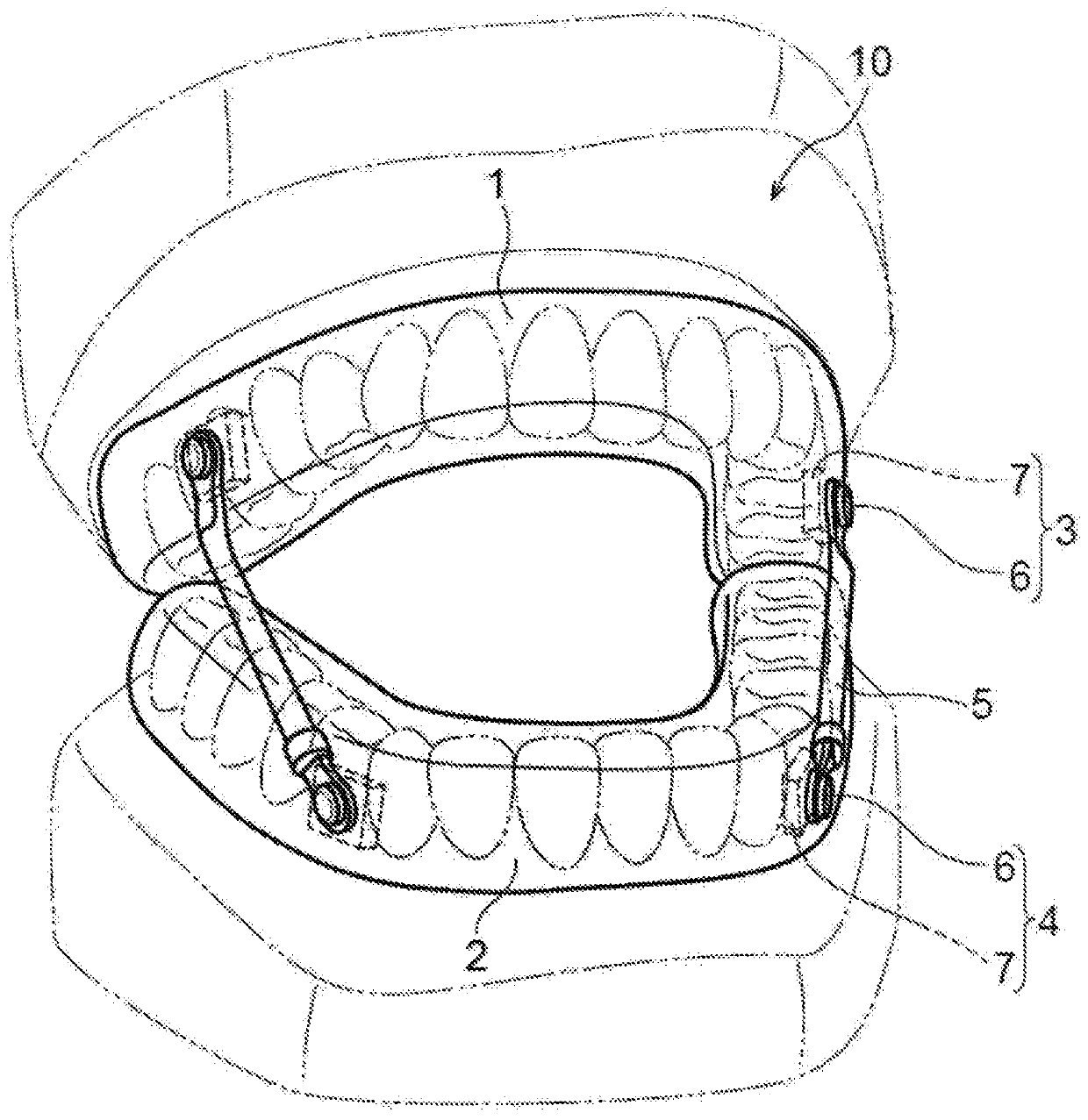

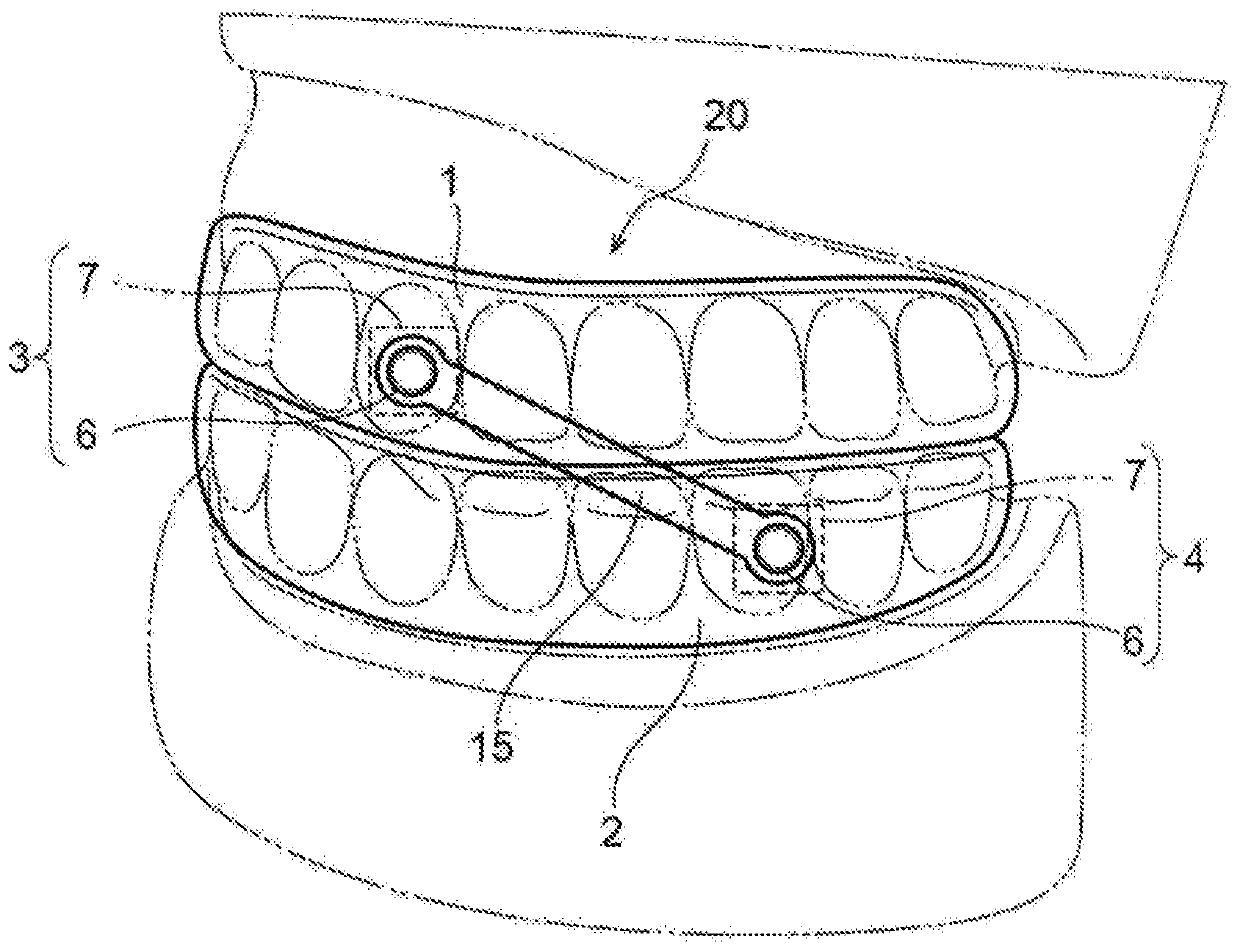

Mouthpiece

A technology of braces and dentition, which is applied in dentistry, orthodontics, orthodontics, etc., and can solve problems such as low followability and poor comfort in the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0415] -Examples 1B and 2B, and Comparative Examples 1B and 2B-

[0416] From the sheet used for the formation of the layer (A), a lithographic plate (A) of 7 cm in length and 2 cm in width was cut out.

[0417] Using "Orthocryl" used in the formation of the layer (B), a 1 mm thick sheet was produced under the same conditions as the production conditions of the layer (B) (volume ratio of powder to liquid, polymerization conditions, etc.), and from the obtained sheet A flat plate (B) of 7 cm in length and 2 cm in width was cut out.

[0418] Adhesive resin (3M DP-8010Blue) is applied to a thickness of 0.1 mm in a region of 1 cm in length and 2 cm in width of the lithographic plate (A), and then the lithographic plate (A) and the lithographic plate (B) are bonded through the adhesive resin. bonding. After 24 hours from bonding, the lithographic plate (B) was stretched in a direction perpendicular to the lithographic plate (A) using ZTS-1000 manufactured by IMADA until it broke,...

Embodiment 1A

[0432] As the innermost layer (T1) sheet, a commercially available olefin-based soft polymer TAFMER DF-810 (manufactured by Mitsui Chemicals Co., Ltd.) was used to produce a soft olefin single-layer sheet with a thickness of 1 mm. In addition, the innermost layer ( T1 ) corresponds to the above-mentioned LI layer.

[0433] As a sheet for the outermost layer (T2), a 1-mm-thick single-layer sheet of isotactic polypropylene (Prime Polypro [registered trademark] F327 (manufactured by Prime Polymer Co., Ltd.)) was prepared. In addition, the innermost layer ( T2 ) corresponds to the above-mentioned LO layer.

[0434] The sheet for the innermost layer (T1) and the sheet for the outermost layer (T2) were laminated and thermally fused to obtain an olefin-based laminated sheet with a thickness of 2 mm.

[0435] The mandible of INVICTUS manufactured by Nissin Co., Ltd. was used as a model for dental braces, and Model Capture Try of Co., Ltd. Matsukaze was used as a molding machine for d...

Embodiment 2A、3A

[0437] TAFMER DF-810 used in the production of the innermost layer (T1) sheet was changed to NOTIO SN-0285 (manufactured by Mitsui Chemicals Co., Ltd.) and VISTAMAXX 6102 (manufactured by ExxonMobil Corporation), respectively. In the same manner as in Example 1A, an olefin-based laminate and a mouthpiece were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com