Sintering-deforming-prevention hollow structure differential mechanism shell machining method

A processing method and differential gear technology, applied in the field of automotive reducers, can solve problems such as deformation of sintered products, difficulty in achieving high precision, easy deformation of side walls, etc., and achieve the effect of ensuring accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

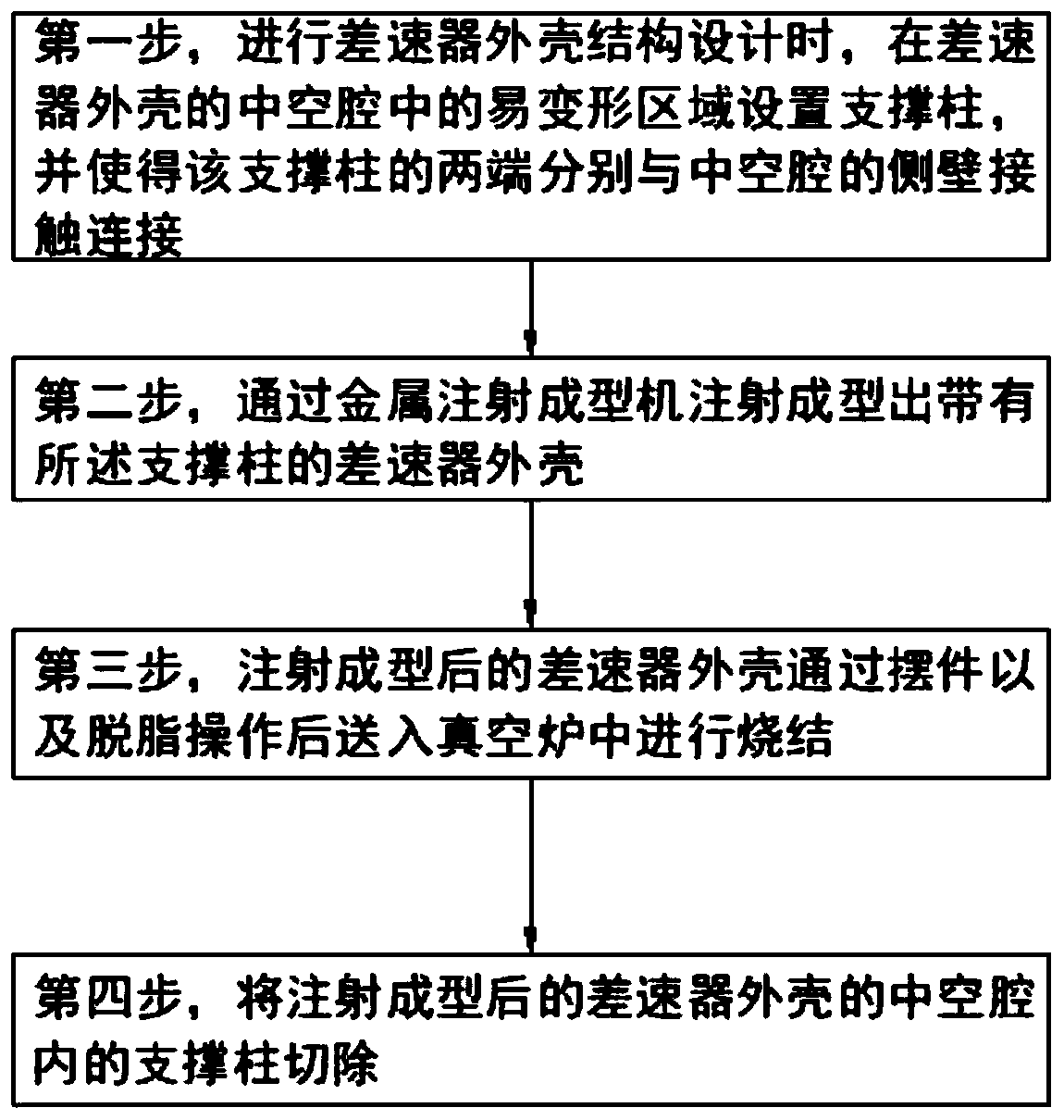

[0017] Such as figure 2 Shown, a kind of anti-sintering deformation hollow structure differential housing processing method has the following steps:

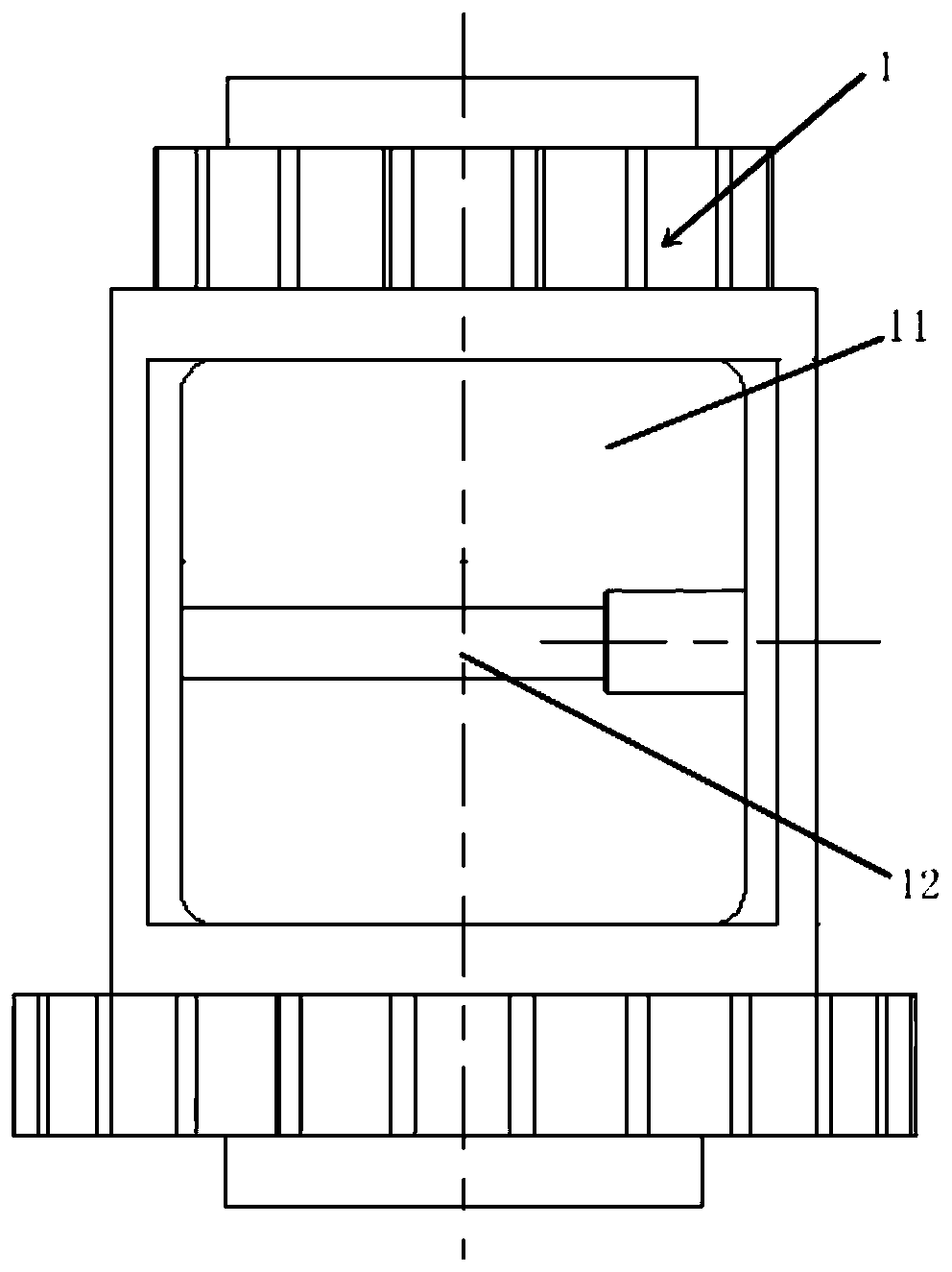

[0018] first step, such as figure 1 As shown, when carrying out the structural design of the differential case 1, the support column 12 is provided in the easily deformable area in the hollow cavity 11 of the differential case 1, and the two ends of the support column 12 are respectively connected to the sides of the hollow cavity 11. Wall contact connection; specifically, when designing the structure of the differential case 1, the support column 12 is placed horizontally in the middle of the easily deformable area in the hollow cavity 11 and is cylindrical, and the easily deformable area can be judged in the unsupported Under the design of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com