3D three-dimensional painting and hot-pressing manufacturing method and application thereof

A production method and technology of three-dimensional painting, applied in decorative arts, embossed ornaments, decorative structures, etc., can solve the problems of poor three-dimensional effect, weak recognition, blurred printing content, etc., and achieve high artistic appreciation value, strong The effect of visual impact and long dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

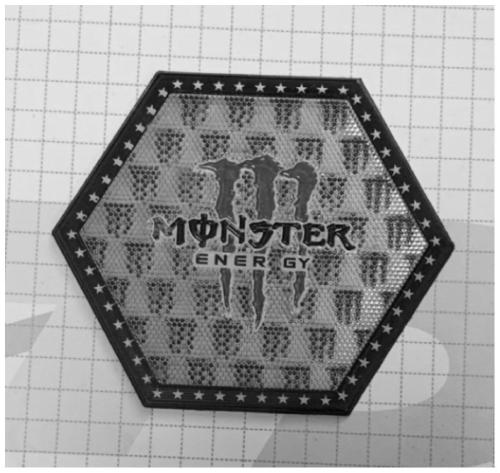

Image

Examples

Embodiment 1

[0020] This embodiment provides a kind of hot-press type manufacturing method of 3D three-dimensional picture, and it comprises the following steps:

[0021] (1) Use the dot grating as the material to make a cylindrical master mold, and then use nickel electroplating technology to replicate the master mold to make a dot grating roller mold for future use.

[0022] (2) Drawing: According to the required images of logo and other products, use PSDTO3D software to make 32 graphics. Among them, the resolution of the graphics is adjusted to 2400PPI, and then use PSDTO3D software to merge. After the merger is completed, a complete image will be formed.

[0023] (3) Printing: using coated paper as a base material, printing the image obtained above by a printer, and drying it naturally to obtain a drawing.

[0024] (4) Bonding: after the ink of the drawings obtained in the printing process is cooled, use strong transparent glue to bond the drawings obtained in the printing process with...

Embodiment 2

[0028] This embodiment provides a kind of hot-press type manufacturing method of 3D three-dimensional picture, and it comprises the following steps:

[0029] (1) Use the dot grating as the material to make a cylindrical master mold, and then use nickel electroplating technology to replicate the master mold to make a dot grating roller mold for future use.

[0030] (2) Drawing: According to the required images of logo and other products, use PSDTO3D software to make 32 graphics. Among them, the resolution of the graphics is adjusted to 2400PPI, and then use PSDTO3D software to merge. After the merger is completed, a complete image will be formed.

[0031] (3) Printing: using coated paper as a base material, printing the image obtained above by a printer, and drying it naturally to obtain a drawing.

[0032] (4) Bonding: After the ink of the drawings obtained in the printing process is cooled, use strong transparent glue to bond the drawings obtained in the printing process with...

Embodiment 3

[0036] This embodiment provides a kind of hot-press type manufacturing method of 3D three-dimensional picture, and it comprises the following steps:

[0037] (1) Use the dot grating as the material to make a cylindrical master mold, and then use nickel electroplating technology to replicate the master mold to make a dot grating roller mold for future use.

[0038] (2) Drawing: According to the images of the required logo and other products, use PSDTO3D software to make 32 graphics. Among them, the resolution of the graphics is adjusted to 2400PPI, and then use PSDTO3D software to merge them. After the merger is completed, a complete image will be formed.

[0039] (3) Printing: using coated paper as a base material, printing the image obtained above by a printer, and drying it naturally to obtain a drawing.

[0040] (4) Bonding: After the ink of the drawings obtained in the printing process is cooled, use strong transparent glue to bond the drawings obtained in the printing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com