Water pump impeller connected in buckled mode

A water pump impeller and buckle-type technology, which is applied to non-variable pumps, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as inaccurate dimensions, and achieve accurate welding dimensions, firm structure, The effect of good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

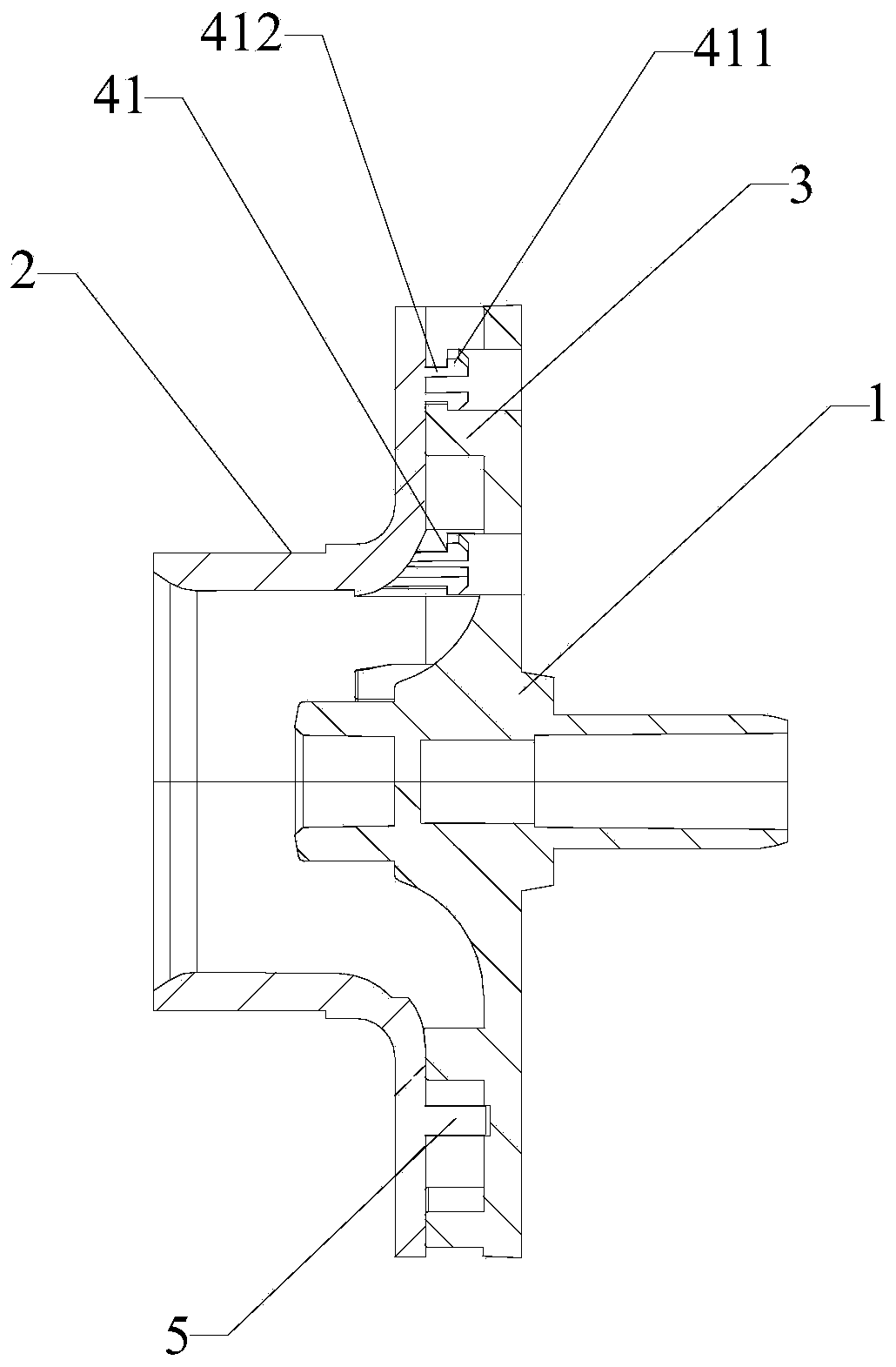

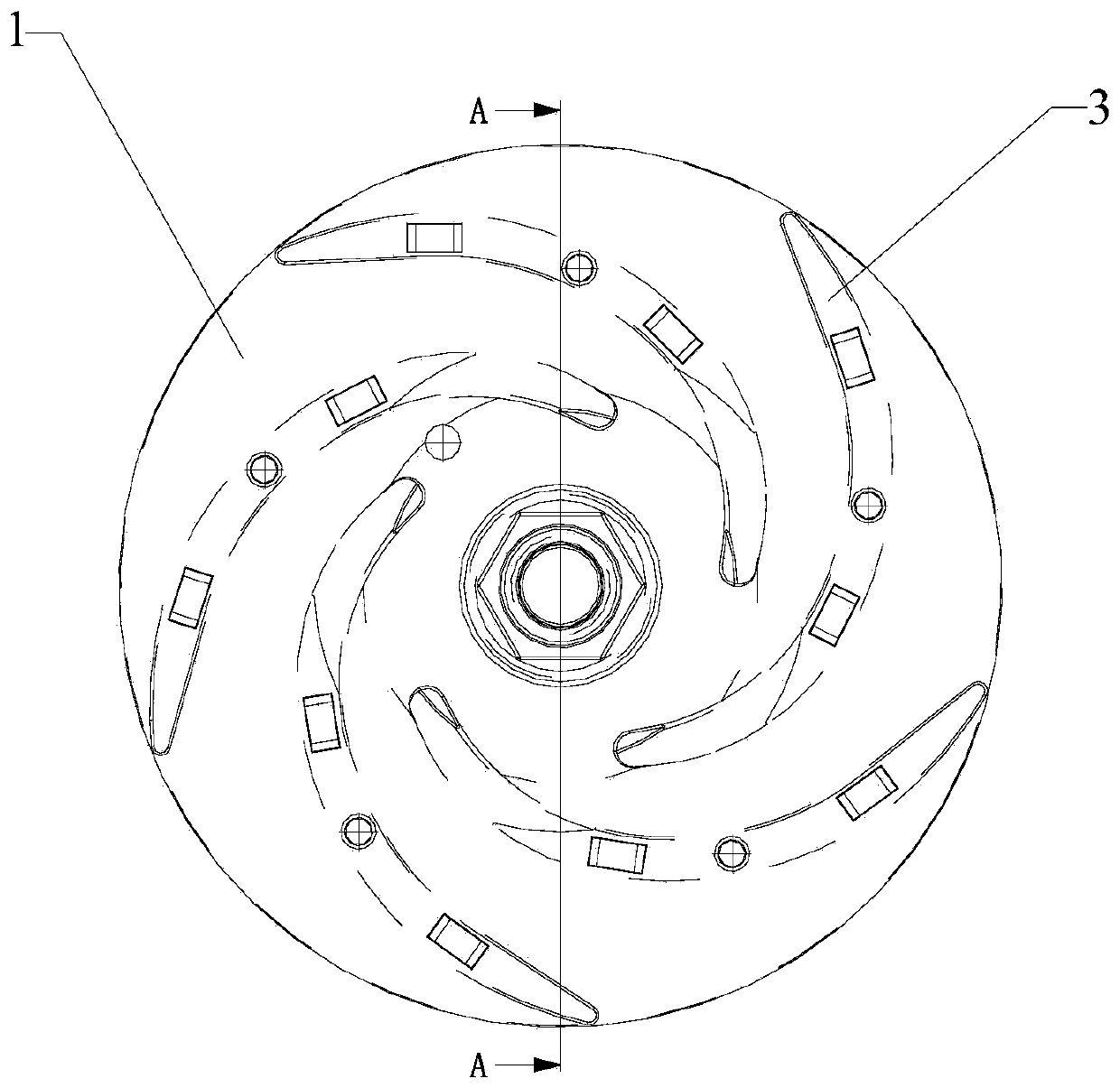

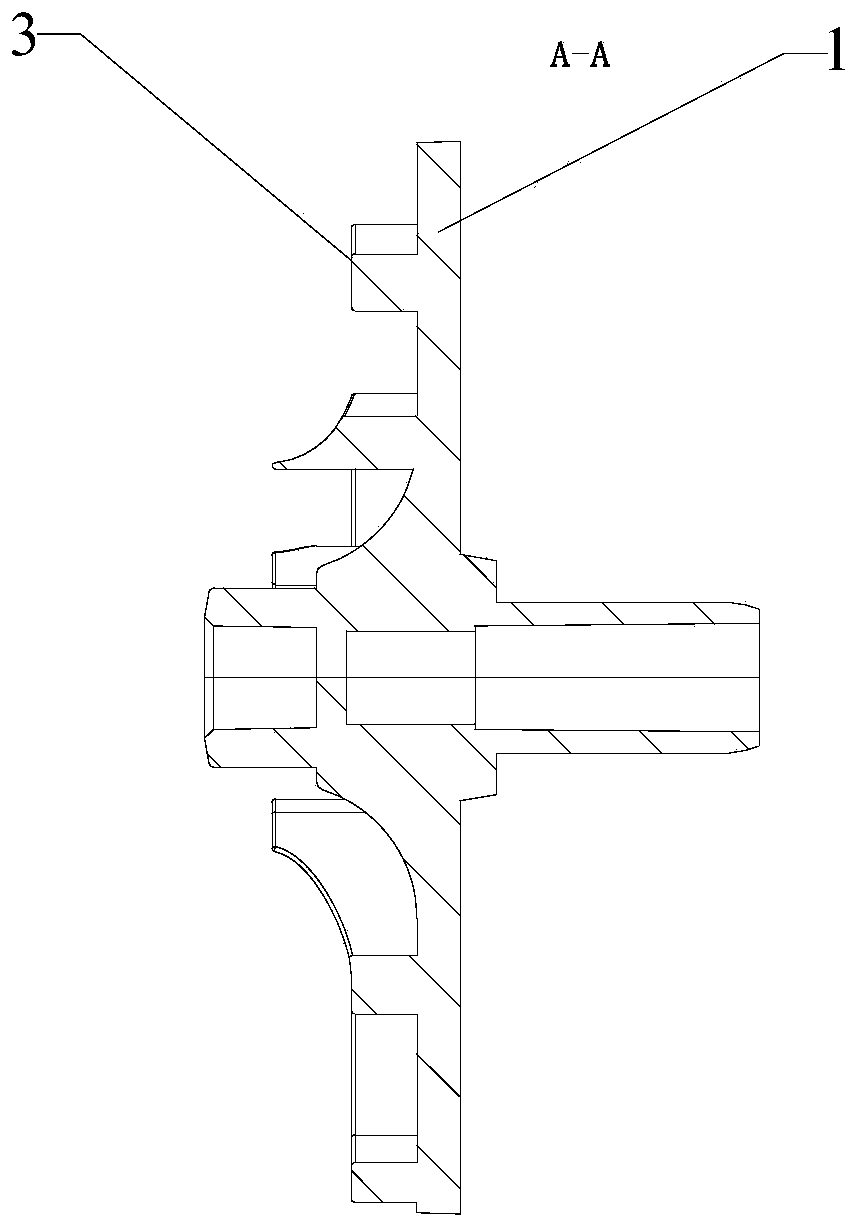

[0029] A buckle-connected water pump impeller, comprising a rear cover 1, a front cover 2 and impeller blades 3, the impeller blades 3 are fixed to the rear cover 1, and the impeller blades 3 are away from the side of the rear cover 1 A plurality of slots are provided, and the front cover 2 is provided with buckles 4 corresponding to the slots one by one. connect. The rear cover 1 and the front cover 2 are connected through the buckle 4 and the card slot. The structure is firm, the positioning is accurate, and it is not loose. Compared with the conventional plastic impeller structure, the front and front cover 2 adopts an ultrasonic welding structure, and the welding size is smaller. Accurate, with better reliability, in terms of processing technology, the buckle 4 can be integrally injection molded with the front cover 2, with high dimensional accuracy. The impeller blades 3 are integrally formed with the rear cover plate 1 . The dimensional accuracy and structural reliabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com