Hydraulic brake stator and hydraulic brake

A brake stator and stator technology, applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., can solve the problems of large oil filling and discharging resistance, unsuitable for high-speed vehicles, long braking response time, etc., to improve safety and weight Lightweight, strong braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

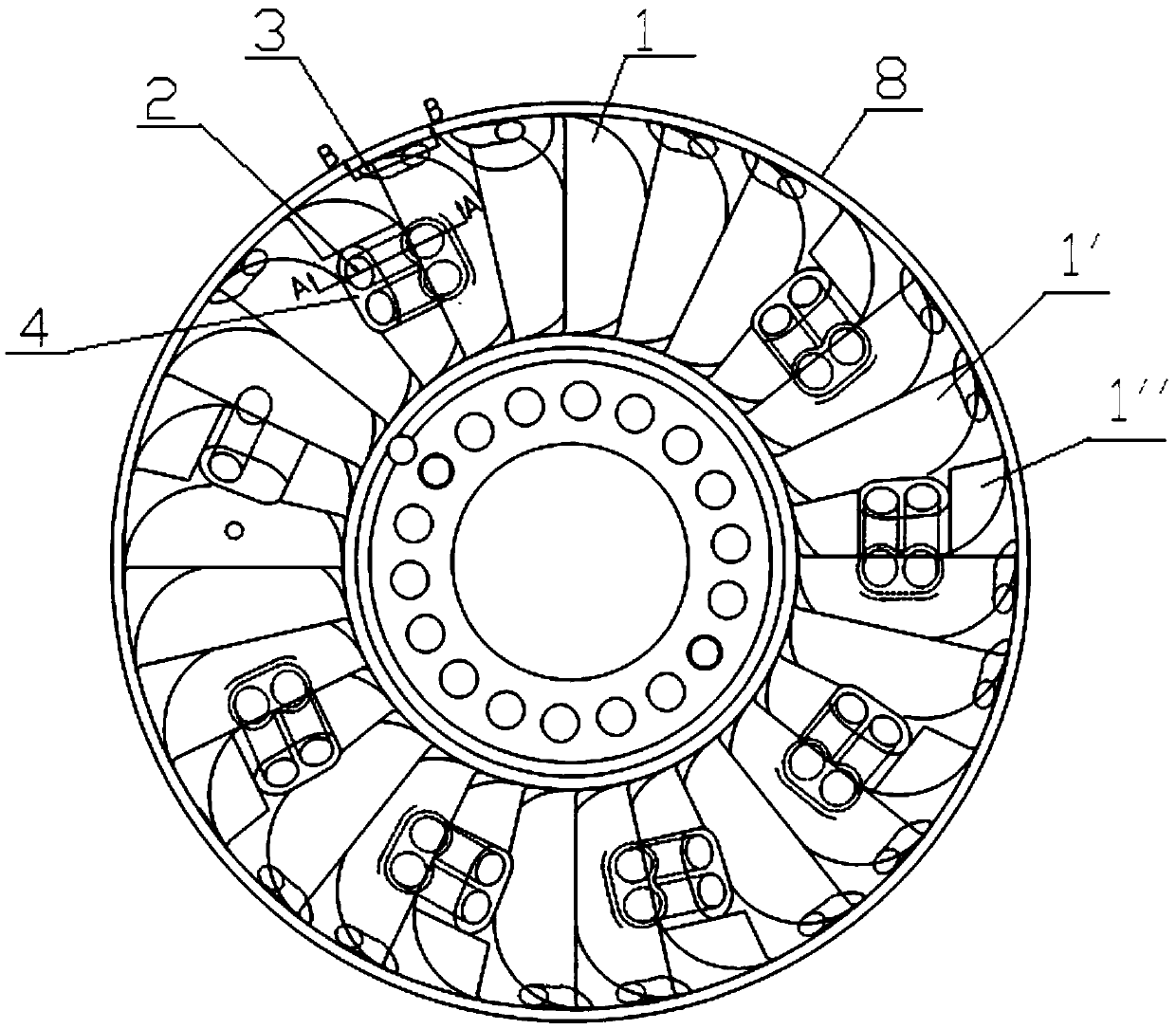

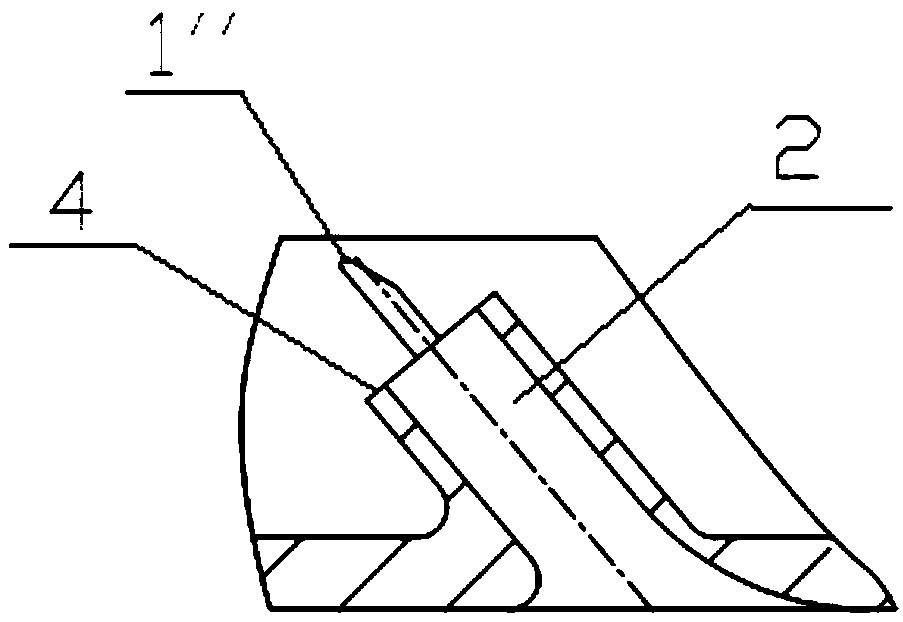

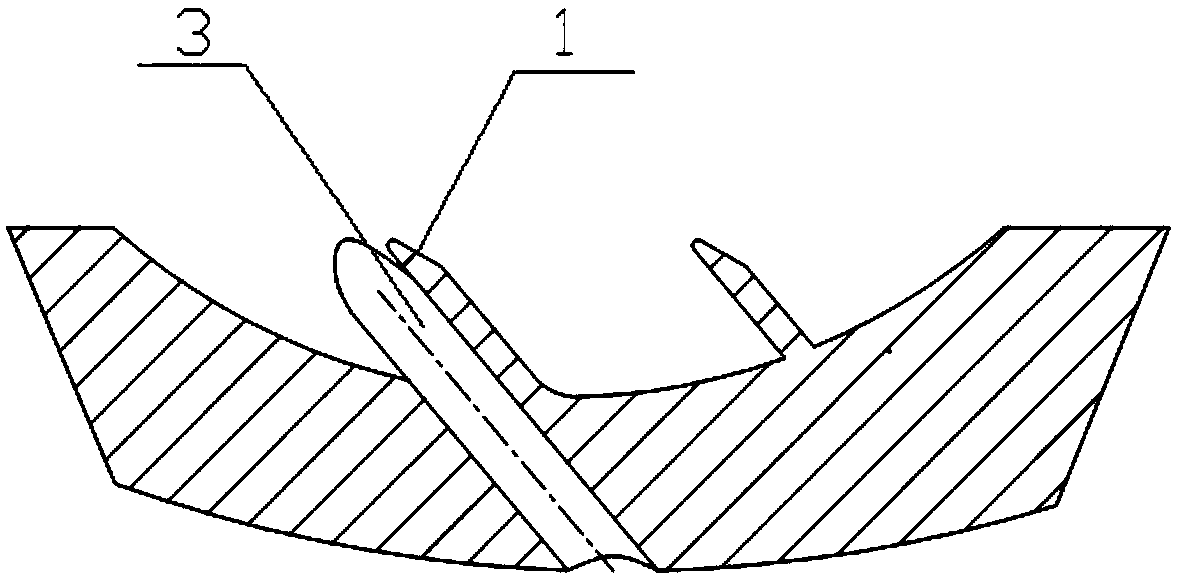

[0031] Such as Figure 1 to Figure 3 As shown, a hydraulic brake stator 8 includes a stator body and a plurality of stator vanes 1 arranged on the stator body, and the stator is provided with an oil inlet hole 2 and an oil discharge hole 3, and the oil inlet hole 2 is from The back side of the stator extends to the front side of the stator through the inside of the stator blade 1, and the oil discharge hole 3 is arranged at the edge of the stator.

[0032] A plurality of stator blades 1 are divided into conventional blades 1' and oil inlet blades 1", the oil inlet holes 2 pass through the inside of the oil inlet blades 1", and the oil inlet blades 1" are provided with the thickness of the part of the oil inlet holes 2 Thickness greater than conventional blades 1'. In this embodiment, a plurality of oil inlet blades 1" are circumferentially distributed on the stator, and two or more conventional blades 1' are arranged between adjacent oil inlet blades 1".

[0033] The middle p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com