Burner cap used for gas stove

A gas stove and fire cover technology, which is applied to the transportation of non-flammable liquid/gas, burners, and combustion methods. Flame performance, applicability enhancement, effect of improving mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

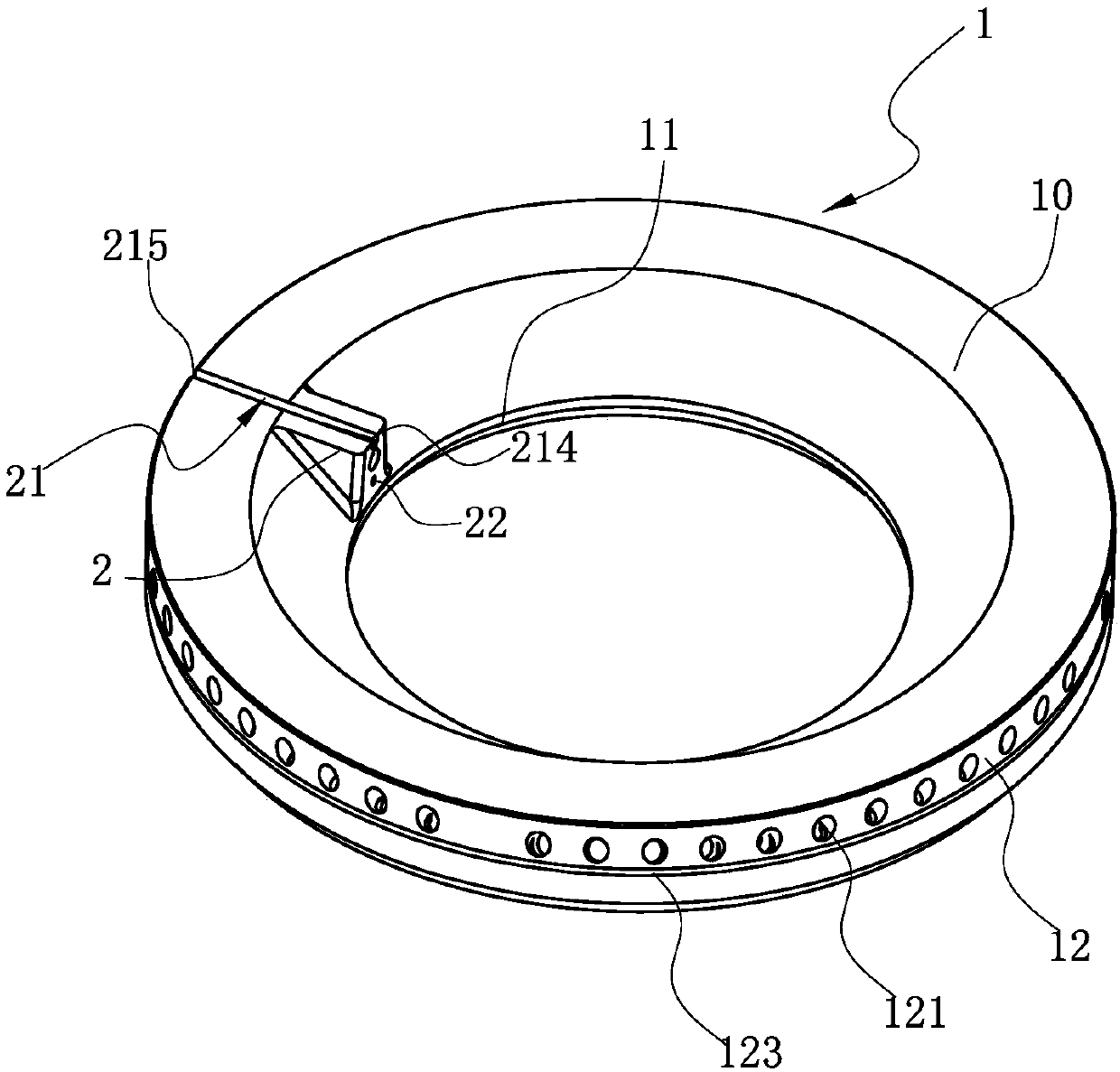

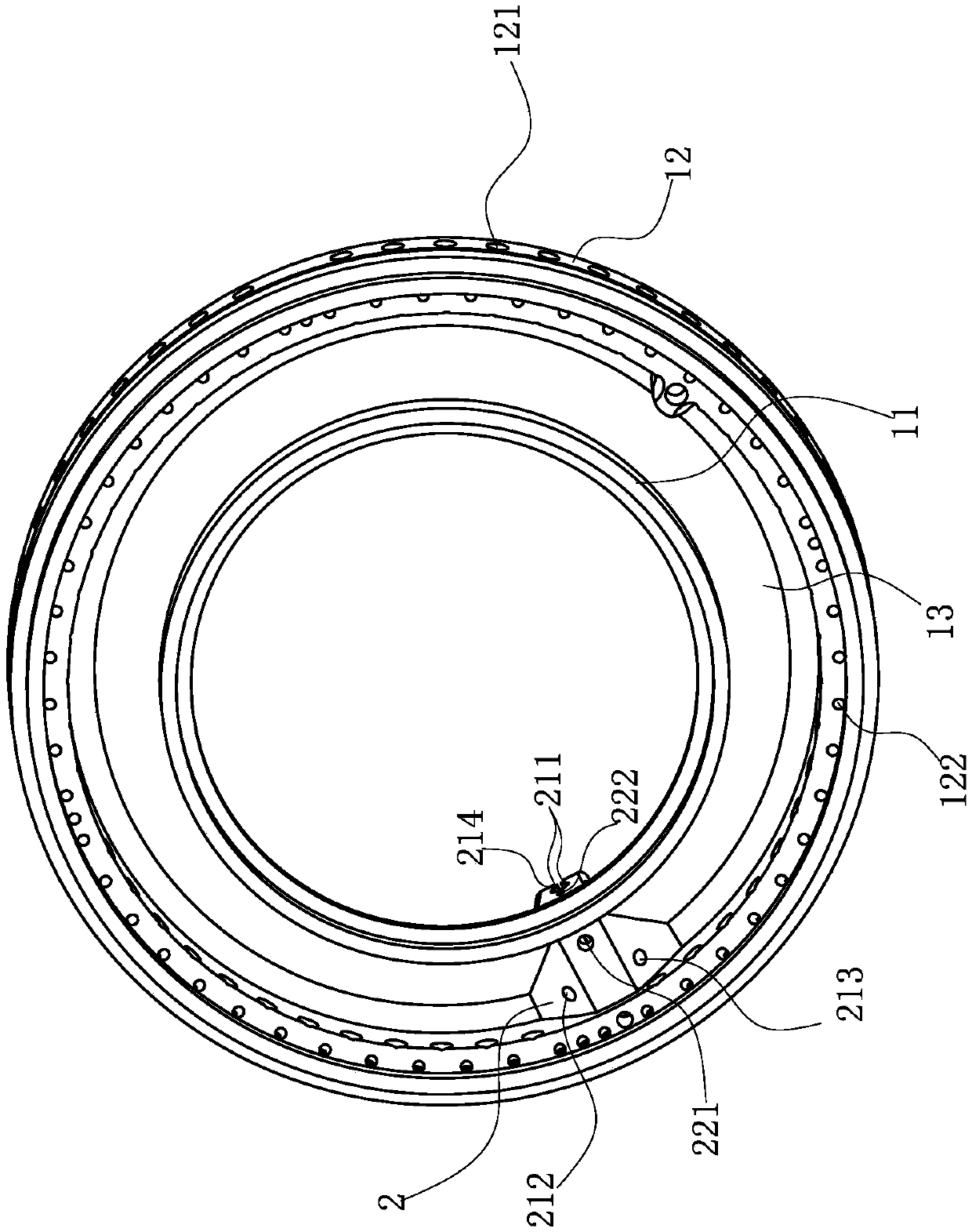

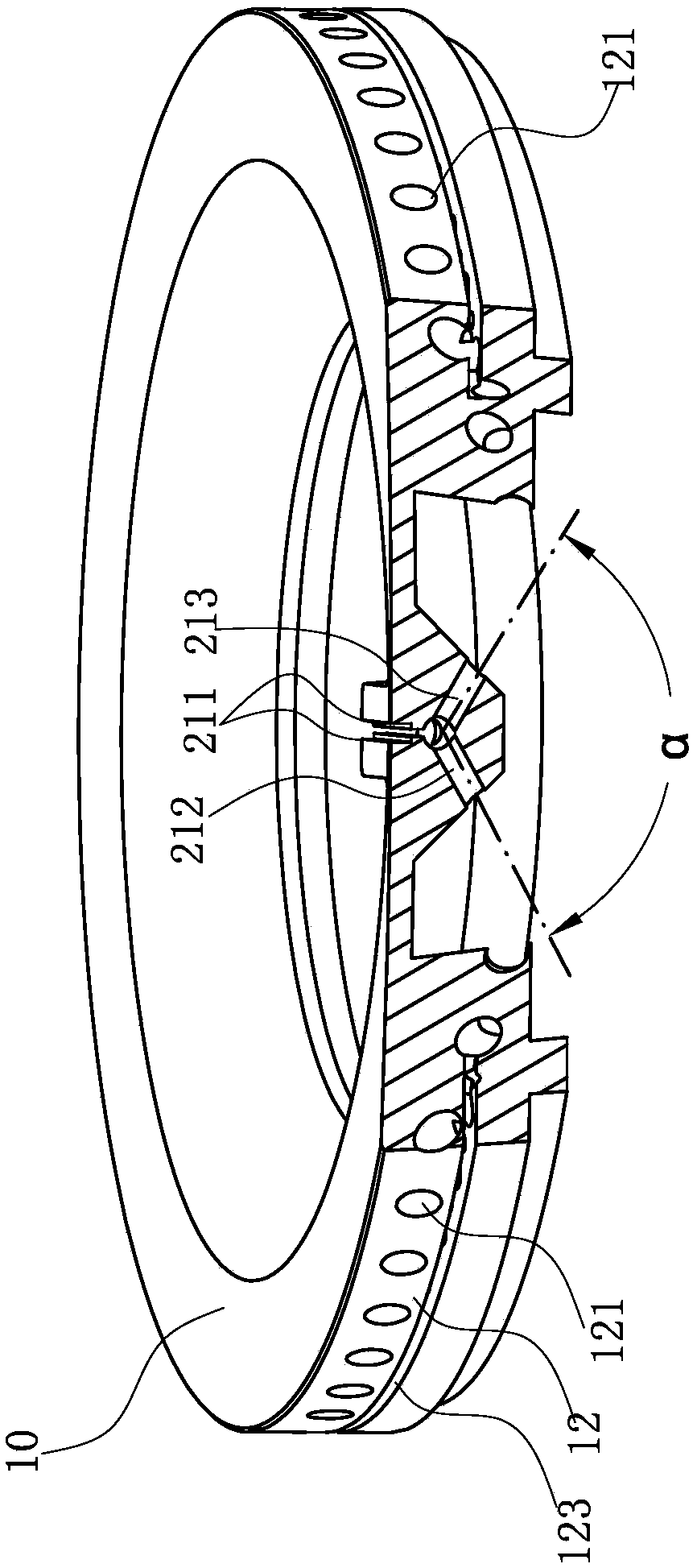

[0025] like Figure 1~5 Shown is the preferred embodiment of the present invention. The fire cover used for the gas stove in this embodiment includes a fire cover body 1, and the annular top wall 10 of the fire cover body 1 extends vertically or obliquely downward from the inner edge and the outer edge of the annular top wall 10. The inner ring wall 11 and the outer ring wall 12 of the inner ring wall 11 and the outer ring wall 12 form a mixing chamber 13, and on the upper surface of the fire cover body 1, there is a transmission tube extending radially outward toward the center of the fire cover body 1 from the inner ring wall 11 to the outer ring wall 12. The fire chamber 2, the top wall of the fire transmission chamber 2 is provided with a fire induction groove 21, and among the two opposite inner side walls of the top opening of the fire induction groove 21, at least one side wall has a protruding towards the other side wall and extends radially. The raised rib 211 and th...

Embodiment 2

[0029] The structure is basically the same as that of Embodiment 1, the only difference is in one place: there is no boss 3, the first through hole 212 and the second through hole 213, the clip where the centerlines of the first through hole 212 and the second through hole 213 intersect The angle α is an obtuse angle, and the impact force of the two relative collisions is greater, so that the gas flowing out of the first through hole 212 and the second through hole 213 is relatively opposed, thereby improving the mixing uniformity of the gas and air in the ignition groove 21, At the same time, the flow rate is reduced and the flame stability performance is improved, such as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com