Automatic drying machine controlled by PLC

A technology of drying machine and drying rack, which is applied in the direction of static material drying machine, partial mixing drying machine, drying machine, etc., which can solve the inconvenience of installation and disassembly of drying plate and body, affect the cleaning and replacement of drying plate, and inconvenient movement of drying plate, etc. problem, to achieve the effect of simple structure, convenient centralized pick and place, easy cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

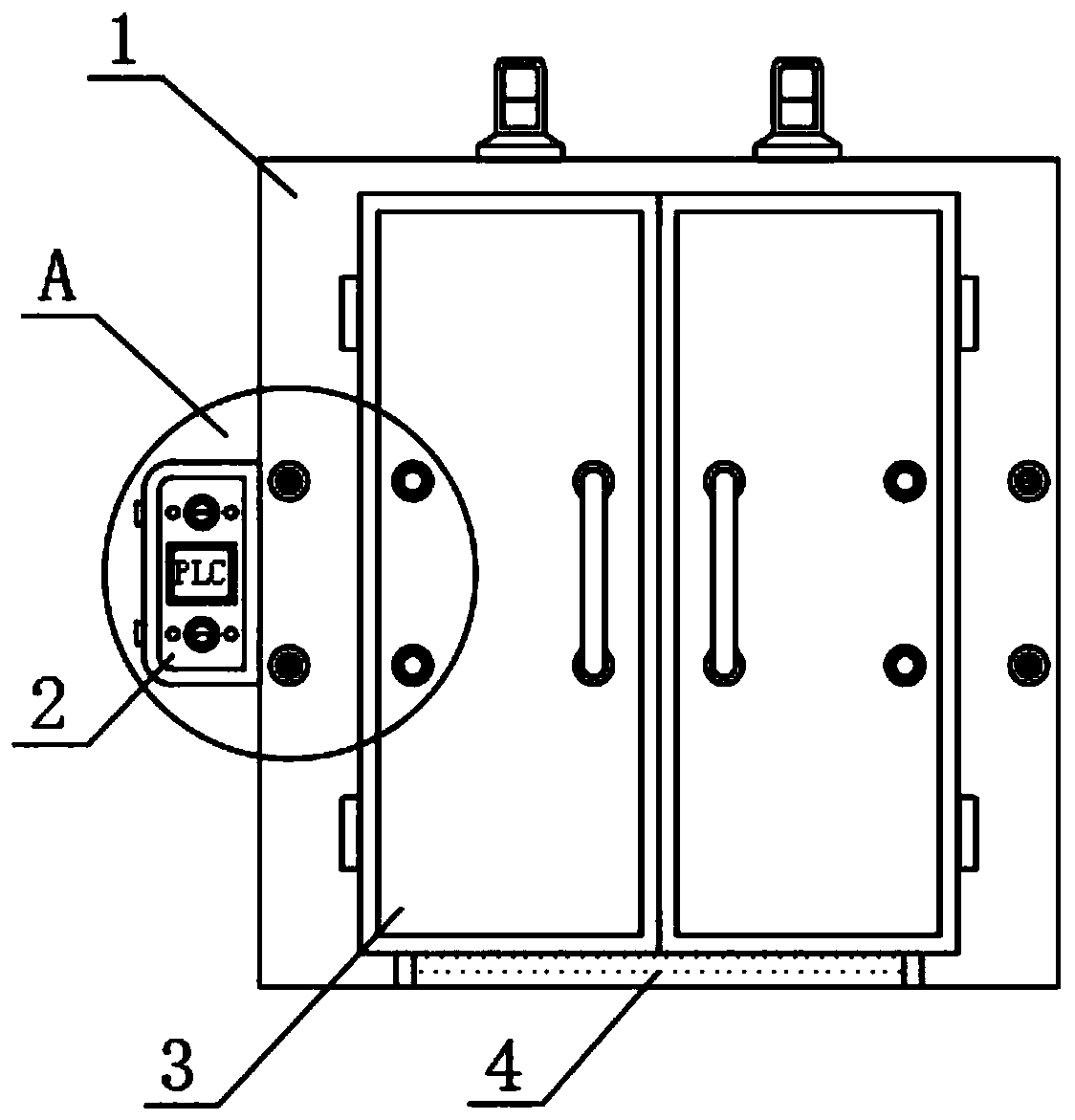

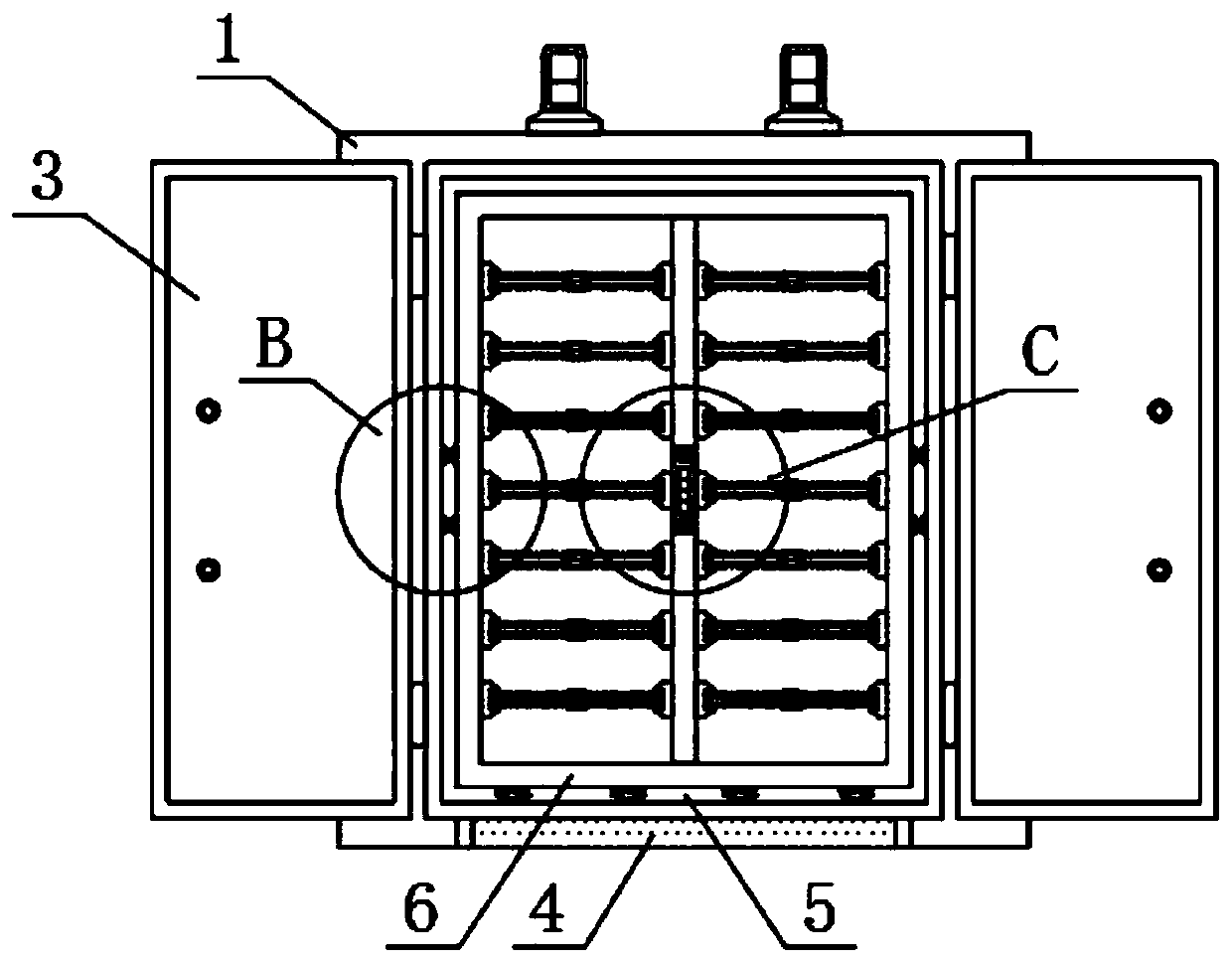

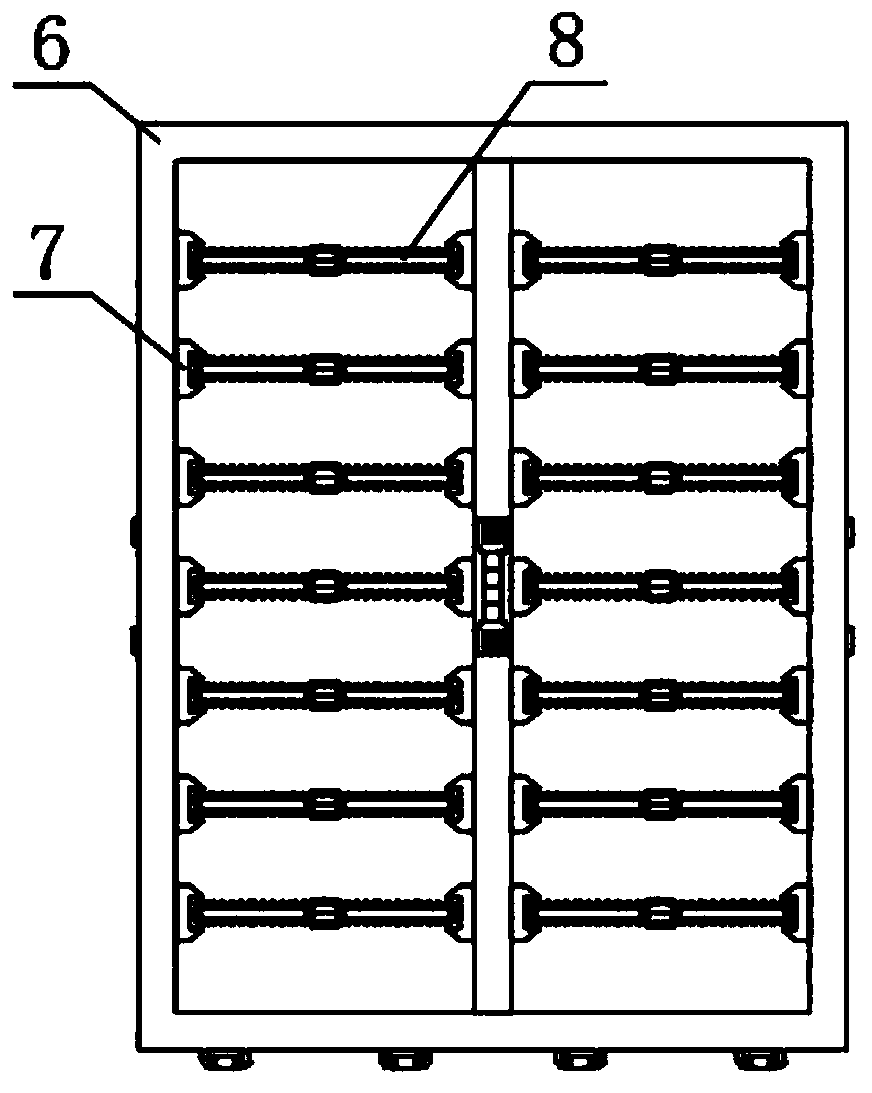

[0025] see Figure 1-8 , the present invention provides the following technical solutions: a PLC-controlled automatic dryer, including a dryer body 1, one side of the dryer body 1, the left and right ends are connected to the door 3 through the rotation of the shaft, the outer surface of the dryer body 1 Several magnetic suction cylinders 10 are fixed on the left and right ends of one side, and several magnetic suction heads 11 are fixed on one side of the outer surface of the warehouse door 3. The inside of the dryer body 1 is provided with a drying chamber 5, and the interior of the drying chamber 5 is provided with Drying frame 6 is arranged, and the both sides of inner surface of drying chamber 5 are all screwed and connected with several rotating shafts 12, and the both sides of outer surface of drying frame 6 are all fixed with several rotary cylinders 13, and the both sides of inner surface of drying frame 6 are arranged on both sides. It is fixed on a number of card ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com