Real-time quantitative detection method for plasticizer spraying amount in online production process of filter stick

A real-time quantification and production process technology, applied in measuring devices, e-liquid filter elements, food science, etc., can solve problems such as loss, unreliable quality, and inconsistency, and achieve the effect of high feedback accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is implemented on the most common KDF2 filter rod forming machine in the tobacco industry.

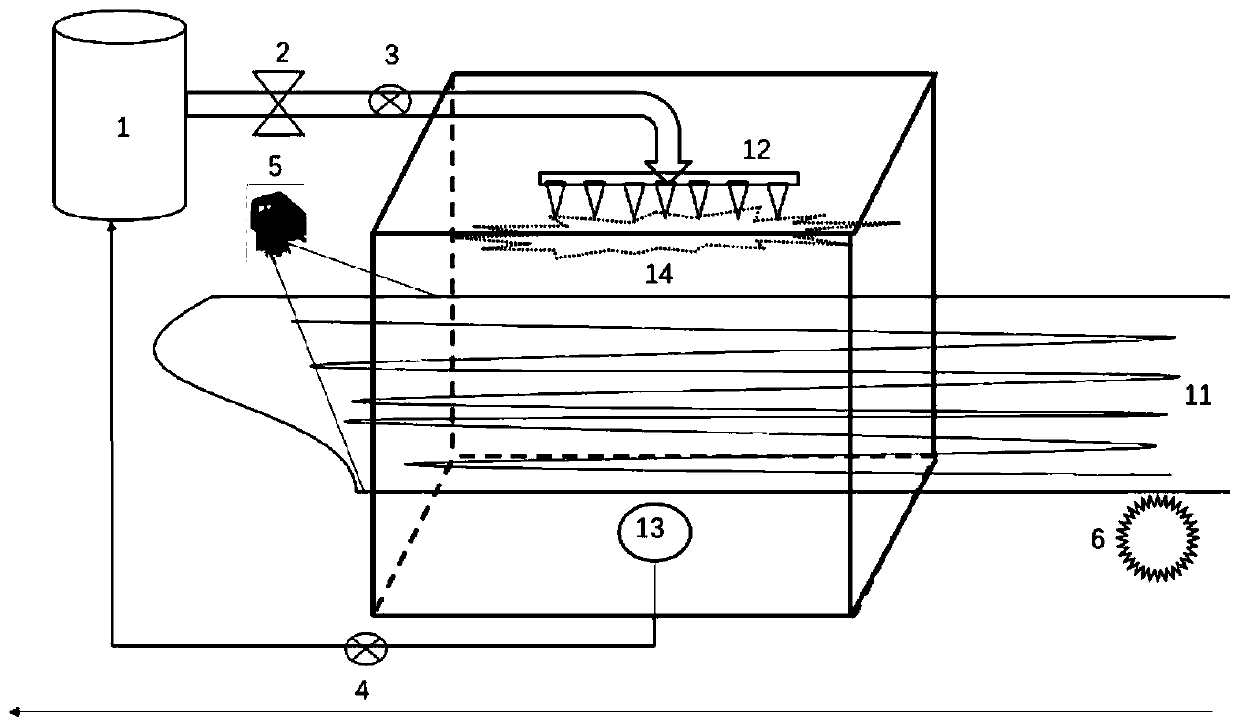

[0034] see figure 1 , the present embodiment provides a real-time quantitative detection system for the amount of plasticizer sprayed, comprising a plasticizer storage device 1, a supply metering pump 2, a spray tank 14, a supply pipeline, a return pipeline 13, a supply flow meter 3, a return flow rate Meter 4, speed measurement sensor 6 and span measurement sensor 5;

[0035] A spray nozzle 12 is arranged above the spray box 14, and the plasticizer storage device 1 delivers plasticizer to the spray nozzle 12 through a supply metering pump 2 and a supply pipeline. The top of the spray box 14 is open to receive the spray nozzle 12 sprayed plasticizers and the inside of the spray box 14 forms a through spray area for the tow to pass through horizontally;

[0036]One end of the return pipeline 13 communicates with the bottom of the spray tank 14 and the other end ...

Embodiment 2

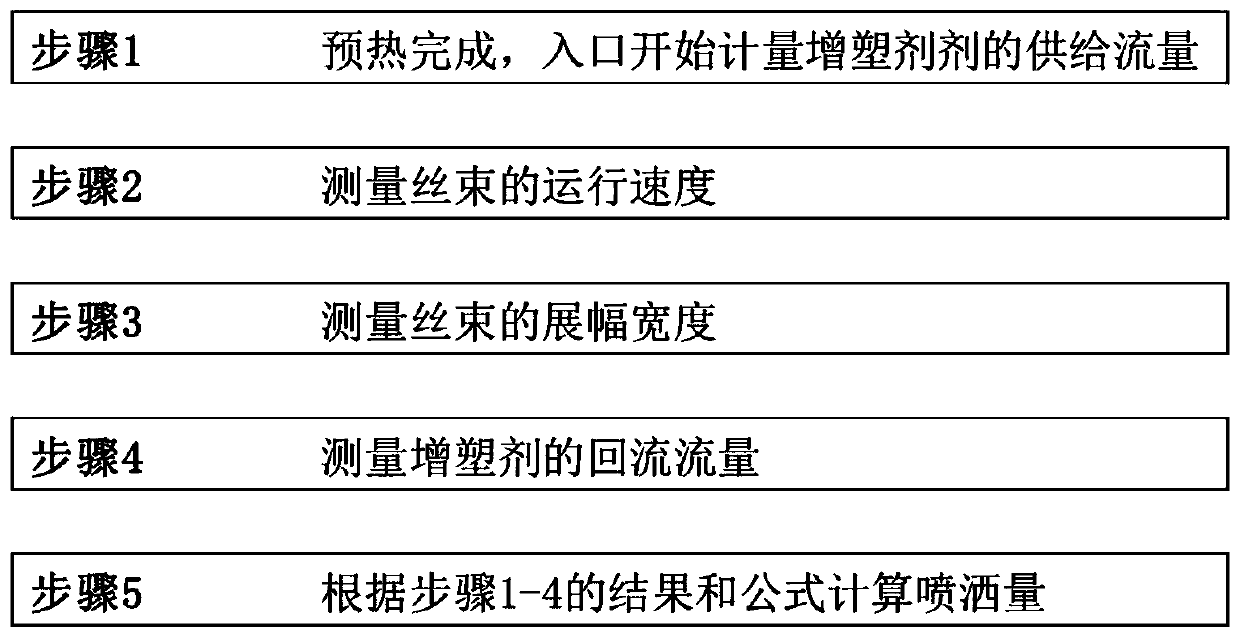

[0047] Based on the system provided in Example 1, see figure 2 , the present embodiment provides a method for real-time quantitative detection of the amount of plasticizer sprayed in the online production process of filter rods, the method comprising the following steps:

[0048] Step 1: The preheating of the plasticizer storage device 1 is completed, the production starts, the plasticizer supply metering pump servo-driven pump 2 is turned on according to the initial metering value, the flow rate starts to be metered, and the supply flow value s is obtained 1 ;

[0049] Step 2: the equipment is started, the tow 11 enters the plasticizer spraying area 14, and the speed measuring sensor 6 measures the running speed v of the tow 11;

[0050] Step 3: The stretch measuring sensor 5 measures the unfolded width d of the tow 11;

[0051] Step 4: The plasticizer returns to the plasticizer storage device 1 through the return hole 13 and the plasticizer return pipeline sensor 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com