Chassis structure of swivel chair

A swivel chair and chassis technology, applied to chairs, chairs with vertically adjustable seats, stools, etc., can solve the problems of difficult and thin design, general transmission stability, and many parts, and achieve simple, ingenious and reasonable structure, and gear transmission The effect of smooth flow and reduced number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

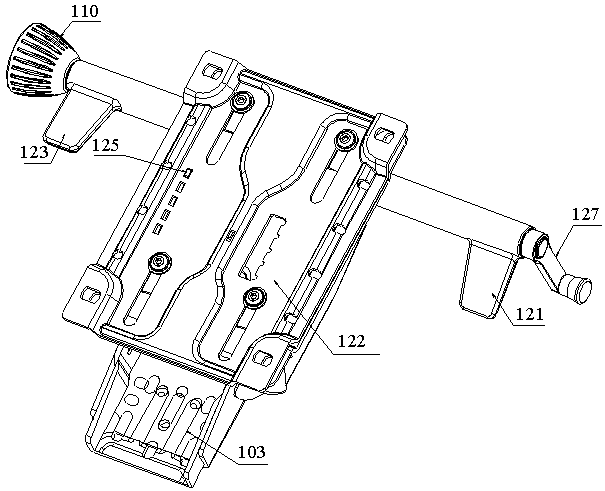

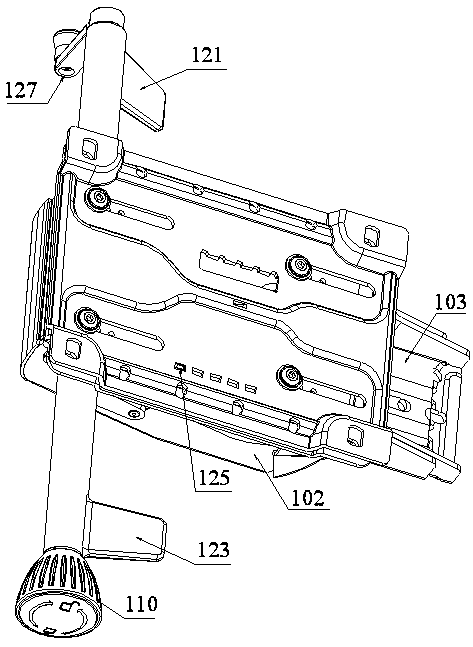

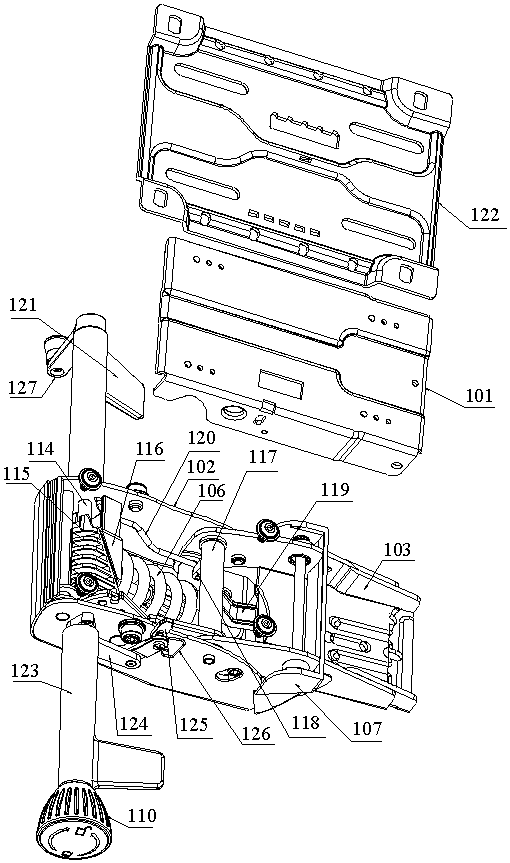

[0019] refer to Figure 1 to Figure 5 , an embodiment of the chassis structure of the swivel chair of the present invention is proposed, including a bottom plate 101, a bottom shell 102 installed on the lower side of the bottom plate 101, a tail plate 103 linked with the backrest, a tilting and free structure that can realize the tilting function, The escape angle locking structure with adjustable escape angle.

[0020] The tilting free structure includes a fulcrum 104 that is connected between the tail plate 103 and the bottom shell 102 and acts as a fulcrum, a rotating shaft 105 that is connected between the tail plate 103 and the bottom shell 102 and can rotate around the fulcrum 104, and is located on The compression spring 106 inside the bottom shell 102 and plays a role in returning the rotating shaft 105 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com