Anti-abrasion inner hole machining drill bit used in shaft sleeve machining process

A processing and anti-wear technology, applied in metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve problems such as wear, poor wear resistance, and reduced service life of drill bits, and achieve enhanced wear resistance , Improve the service life and avoid wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

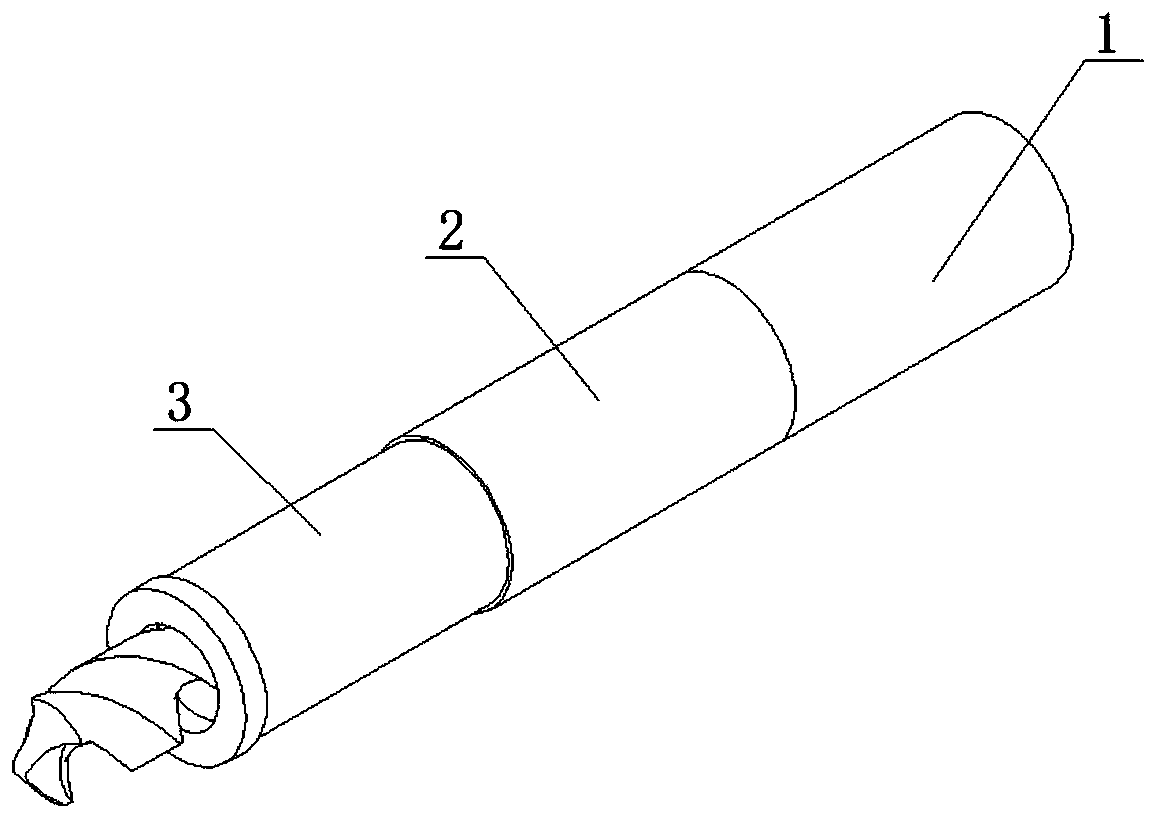

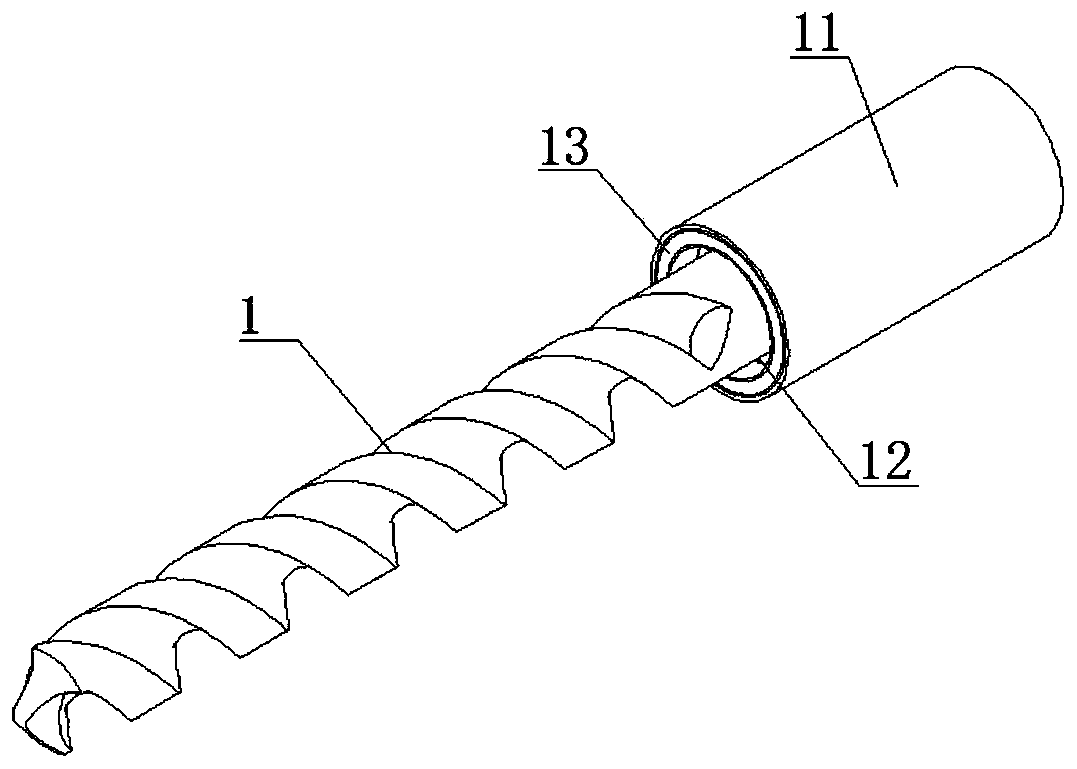

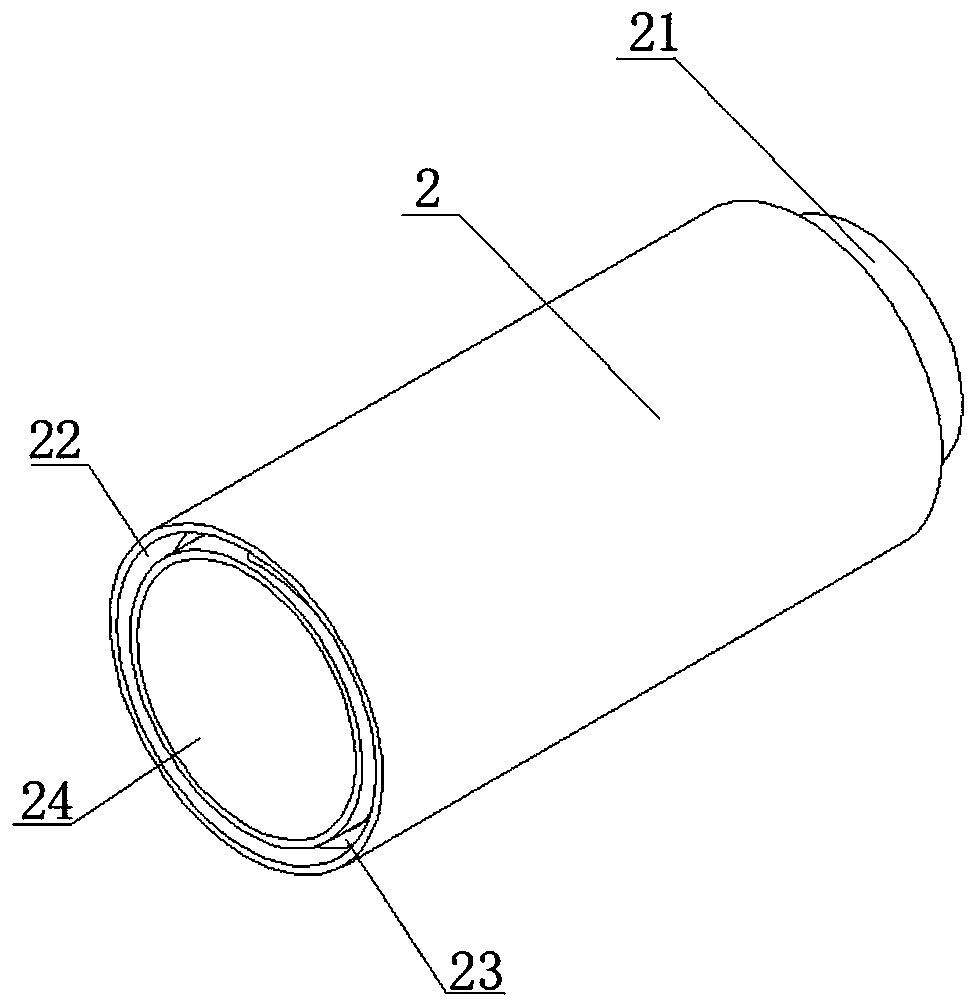

[0020] Example: refer to figure 1 , figure 2 and image 3 Shown: a wear-resistant inner hole processing drill bit used in the process of shaft sleeve processing, including a drill bit 1, a connector 11 is provided at the rear end of the drill bit 1, a bearing 13 is provided at the front end of the connector 11, and the bearing 13 is interference-connected with a protective shell 2. There is a spring 23 inside the protective case 2, and the indenter 31 is plugged inside the protective case 2, and the indenter 31 and the spring 23 are fixedly connected together; the connector 11 is convenient for the drill bit 1 and the equipment to be connected together, so as to facilitate the drilling. 1. There is equipment to drive the rotation, which is convenient for the drill bit 1 to drill the shaft sleeve blank. The bearing 13 is convenient for the rotation of the protective shell 2, so as to avoid relative rotation between the protective shell 2 and the drill bit 1, and to effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com