Working frame for machining

A machining and work frame technology, applied in the direction of grinding workpiece supports, metal processing equipment, metal processing machinery parts, etc., can solve problems such as poor applicability, weak adjustment ability, and inability to process parts, and achieve convenient installation and removal. Practicality and functionality, the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

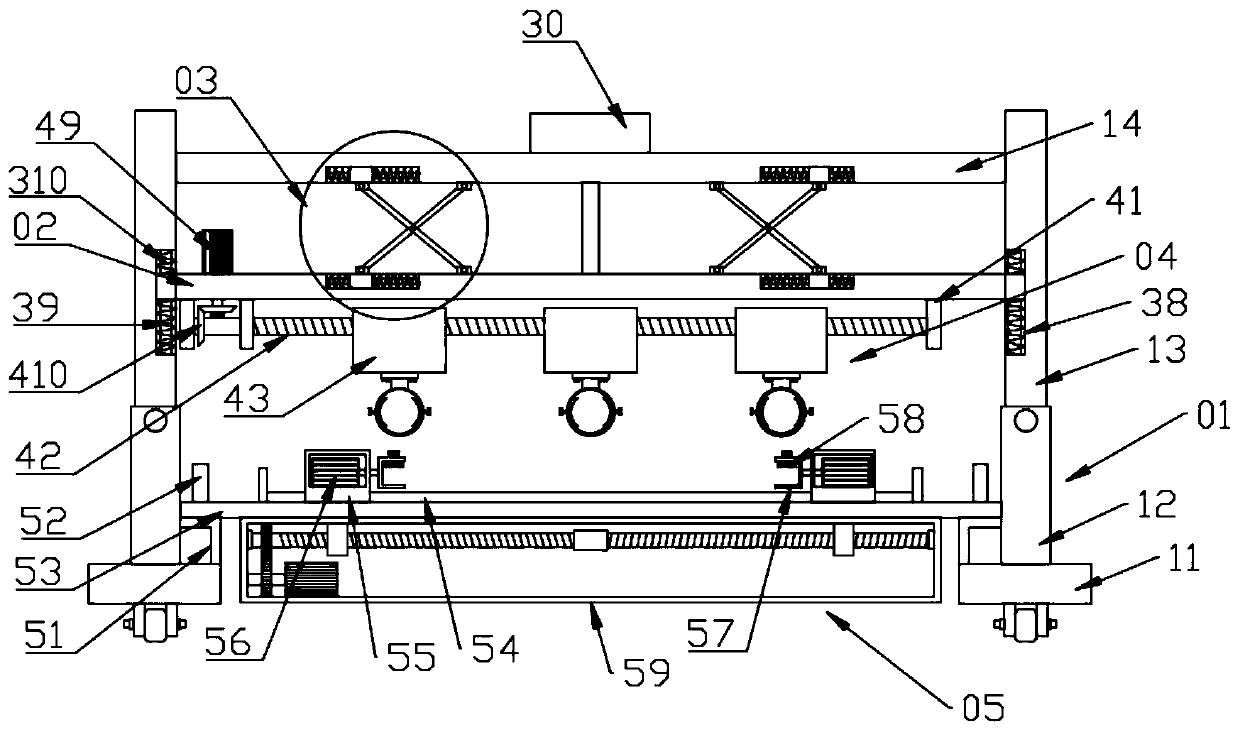

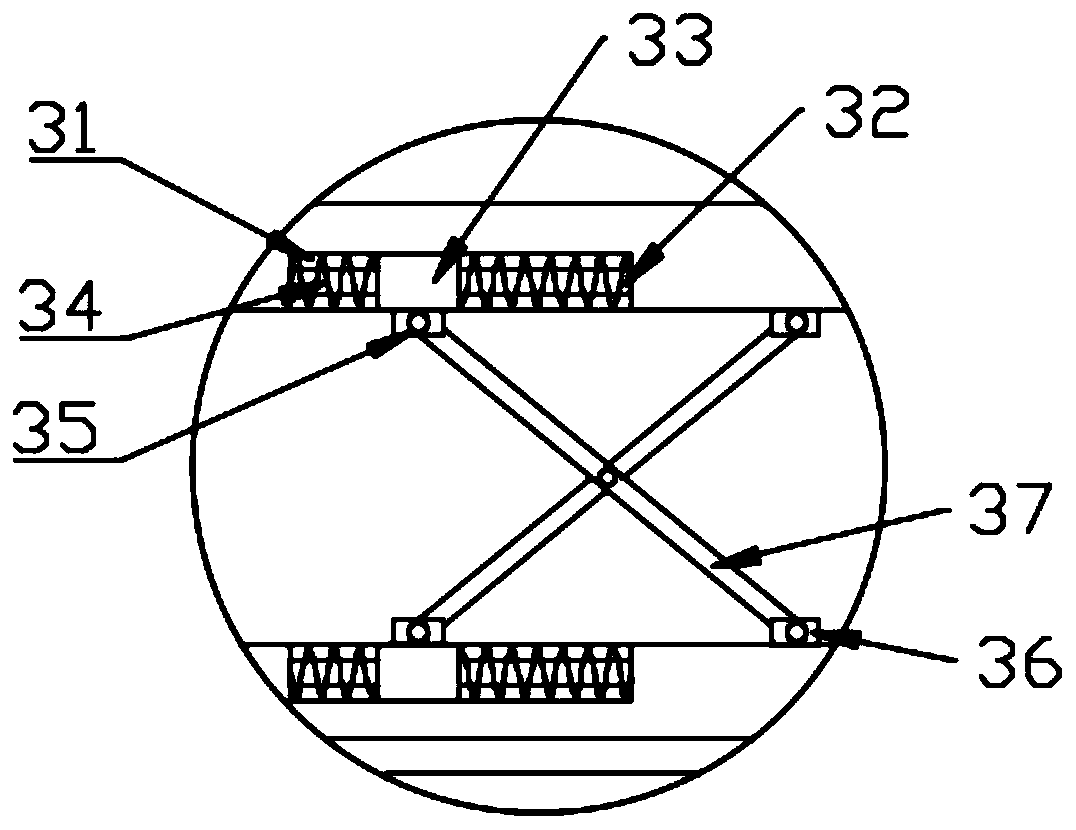

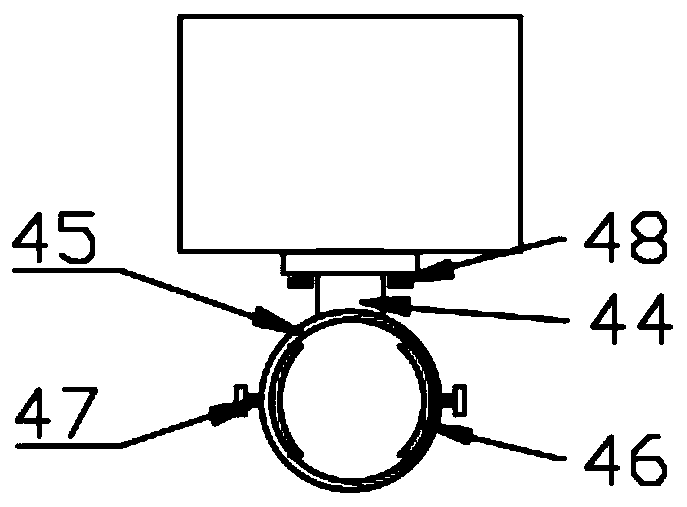

[0026] see Figure 1~3 , in an embodiment of the present invention, a working frame for mechanical processing includes a bracket assembly 01, the bracket assembly 01 is used to play a role in supporting the whole, and can improve the overall stability; the bracket assembly 01 is slidably connected with a support Plate 02, that is, the support plate 02 can slide on the support assembly 01, and then the position of the support plate 02 can be adjusted; the support assembly 01 and the support plate 02 are provided with a height adjustment assembly 03, through which the height adjustment assembly 03 can play a role The adjustment function of the support plate 02 can also improve its stability while adjusting, and has very good practicability; in addition, the support plate 02 is also equipped with a level adjustment component 04, and the level adjustment component 04 is equipped with a clamping Assemblies, the horizontal adjustment assembly 04 can drive the clamping assembly to mo...

Embodiment 2

[0034] The bracket component 01 is also provided with an auxiliary fixing component 05, which can play an auxiliary fixing role through the auxiliary fixing component 05, thereby making it more convenient to fix the parts, and at the same time it is convenient to disassemble. When it is not needed, it can be directly removed , making the overall applicability better.

[0035] Further, the auxiliary fixing assembly 05 includes a backing plate 51 fixed on the bracket assembly 01, an insertion rod 52 is fixed above the backing plate 51, and a placement plate 53 is inserted on the insertion rod 52. When installing, directly place the placement plate 53 is inserted on two inserting rods 52 and can finish the installation of placing plate 53, very simple; Said placing plate 53 is fixed with slide rail 54, and slide rail 54 is slidably connected with mobile box 55, and promptly mobile box 55 can Slide on slide rail 54, and then adjust the position of mobile box 55, be provided with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com