Six-freedom-degree parallel robot mechanism

A robot and degree-of-freedom technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as restricting the attitude ability of the motion platform, and achieve the effect of not easy to interfere with each other, large working space, and large turning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

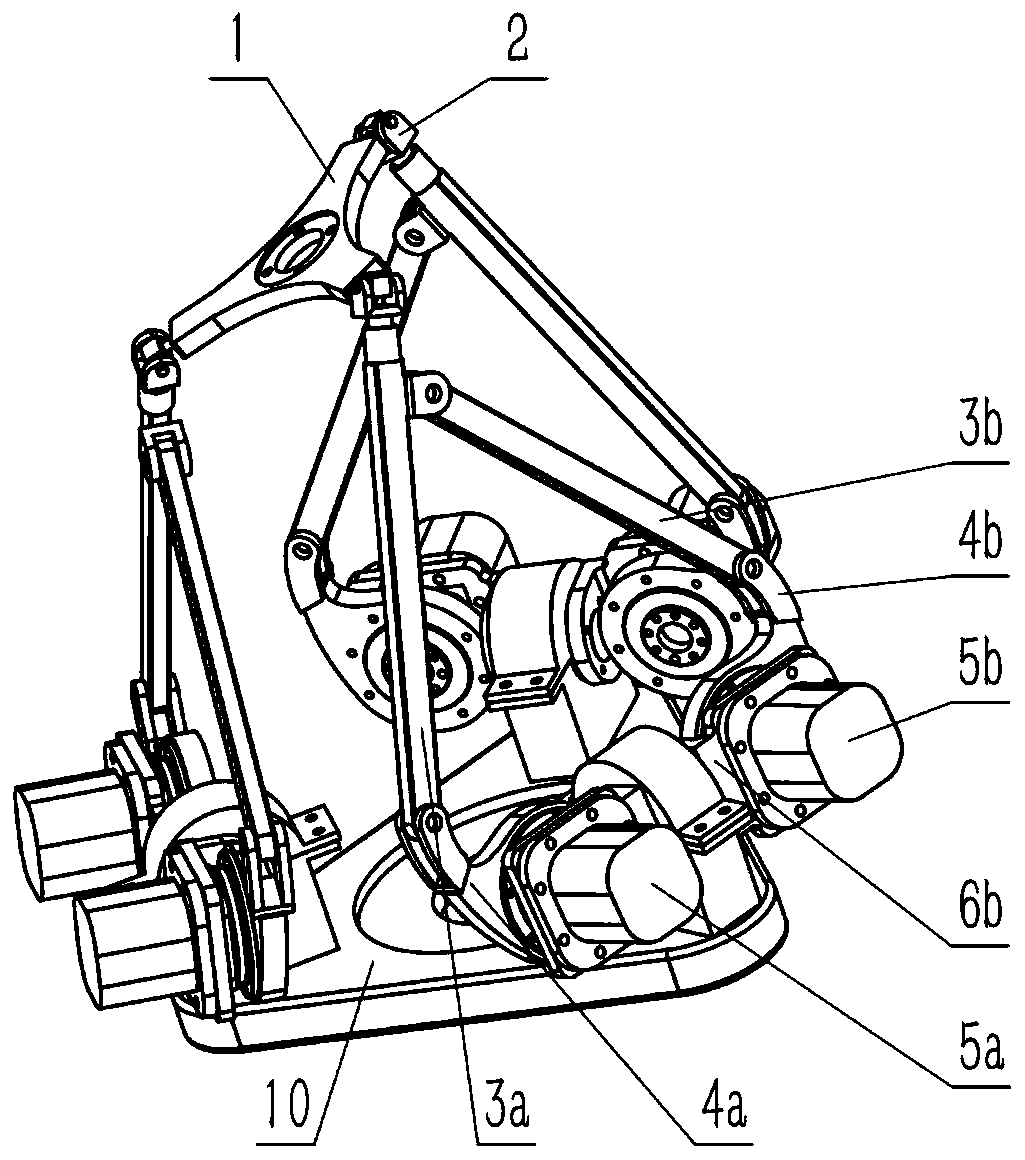

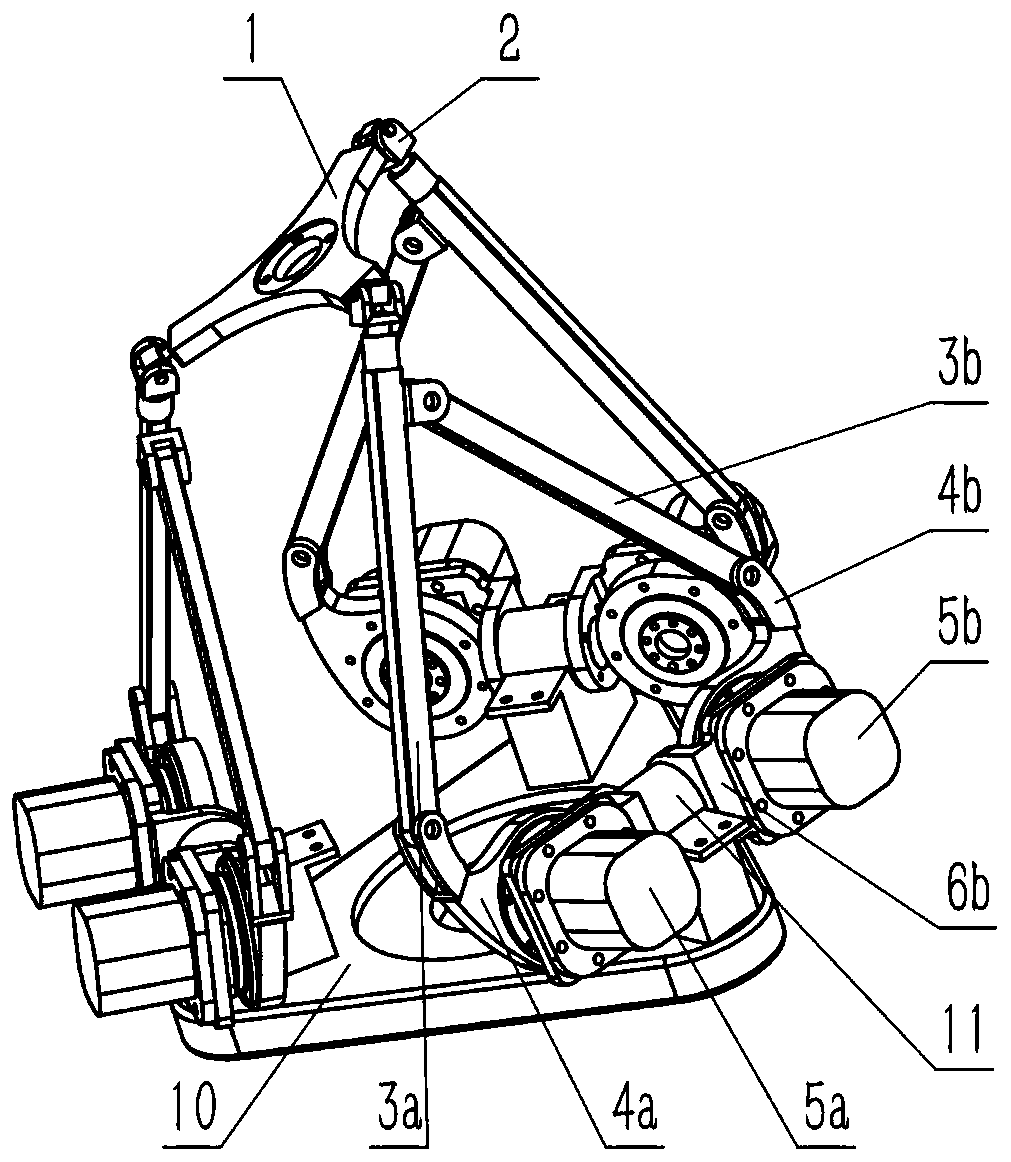

[0018] Such as figure 1 with figure 2 As shown, a six-degree-of-freedom parallel robot in this embodiment includes a static platform 10, a moving platform 1, and three double-drive compound kinematic branch chains connected in parallel between the static platform 10 and the moving platform 1; the double-drive The compound kinematic branch chain is composed of a plane five-bar mechanism, the static platform 10 is connected with the double-drive compound kinematic branch chain through a rotating pair, and the dynamic platform 1 is connected with the double-drive compound kinematic branch chain through a ball joint 2 .

[0019] The double-drive composite kinematic branch chain includes a rotating rod 11, a first driving rod 4a, a first driven rod 3a, a second driven rod 3b and a second driving rod 4b; the rotating rod 11, the first driving rod 4a, the first driven rod 3a, the second driven rod 3b and the second active rod 4b are successively connected by rotating pairs whose ax...

Embodiment 2

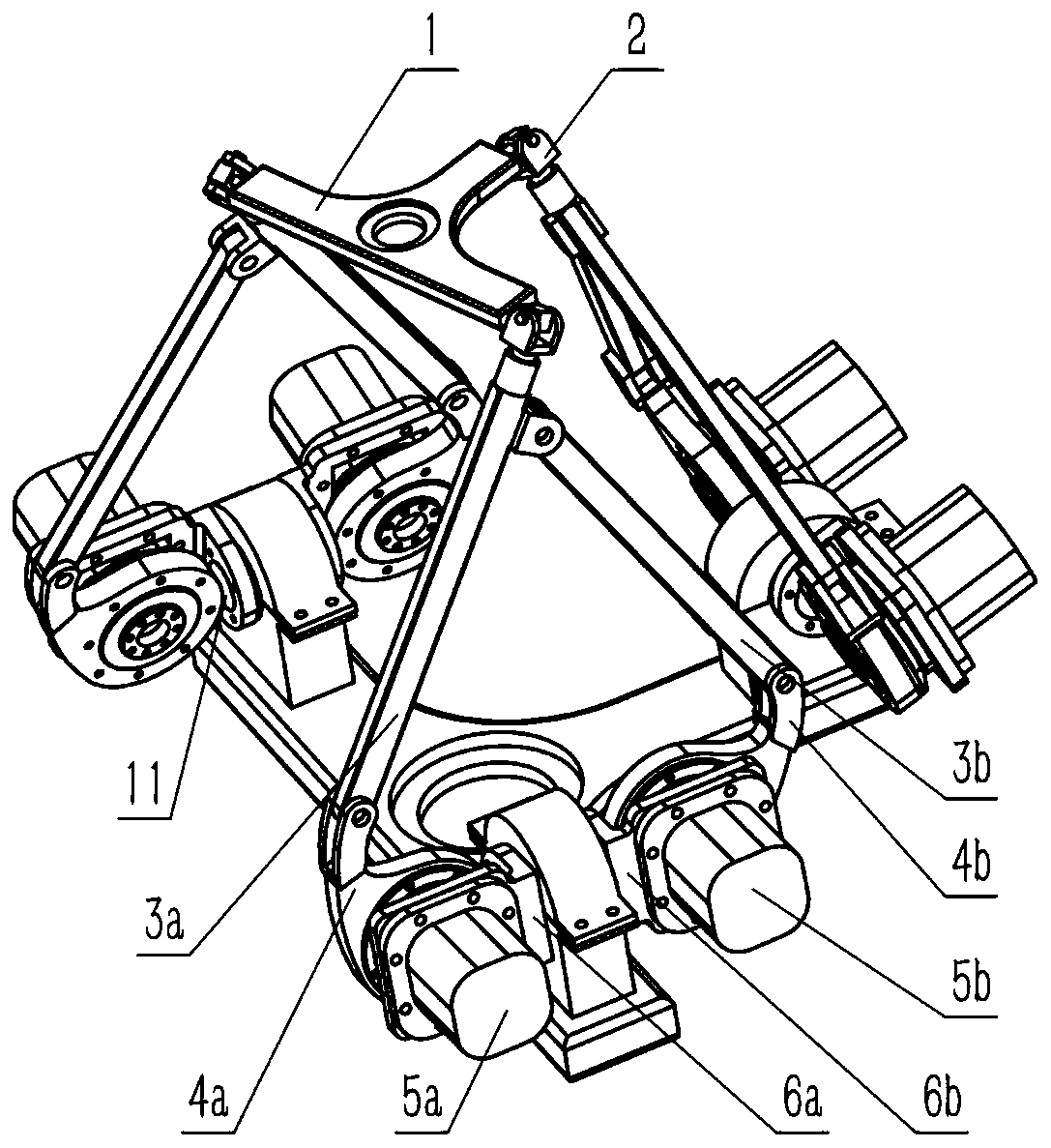

[0022] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the axis of the rotating pair of the first double-drive compound kinematic branch chain connected to the static platform 10 is the same as that of the second double-drive compound kinematic branch chain connected to the static platform 10. The axes are perpendicular to each other, and the axis of the revolving pair connected to the static platform 10 by the second double-drive compound kinematic branch chain is perpendicular to the axis of the revolving pair connected by the third double-drive compound kinematic branch chain and the static platform 10, and the first The axis of the revolving pair connected to the static platform 10 by a double-drive compound kinematic branch chain is parallel to the axis of the revolving pair connected to the static platform 10 by the third double-drive compound kinematic branch chain. The structure of the three double-drive compound kinematic bra...

Embodiment 3

[0024] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 lies in that the axes of the three double-drive compound kinematic branch chains and the rotating pairs connected to the static platform 10 intersect at one point. The structure of the three double-drive compound kinematic branch chains is the same as that of embodiment 1, and the connection mode of the double-drive compound kinematic branch chains with the dynamic platform and the static platform is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com