Glutinous rice cake seal device

A technology of seals and glutinous rice cakes, applied in printing, stamping, etc., can solve the problems of troublesome operation, easy soreness, low work efficiency, etc., and achieve the effect of convenient operation, avoiding sore hands and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

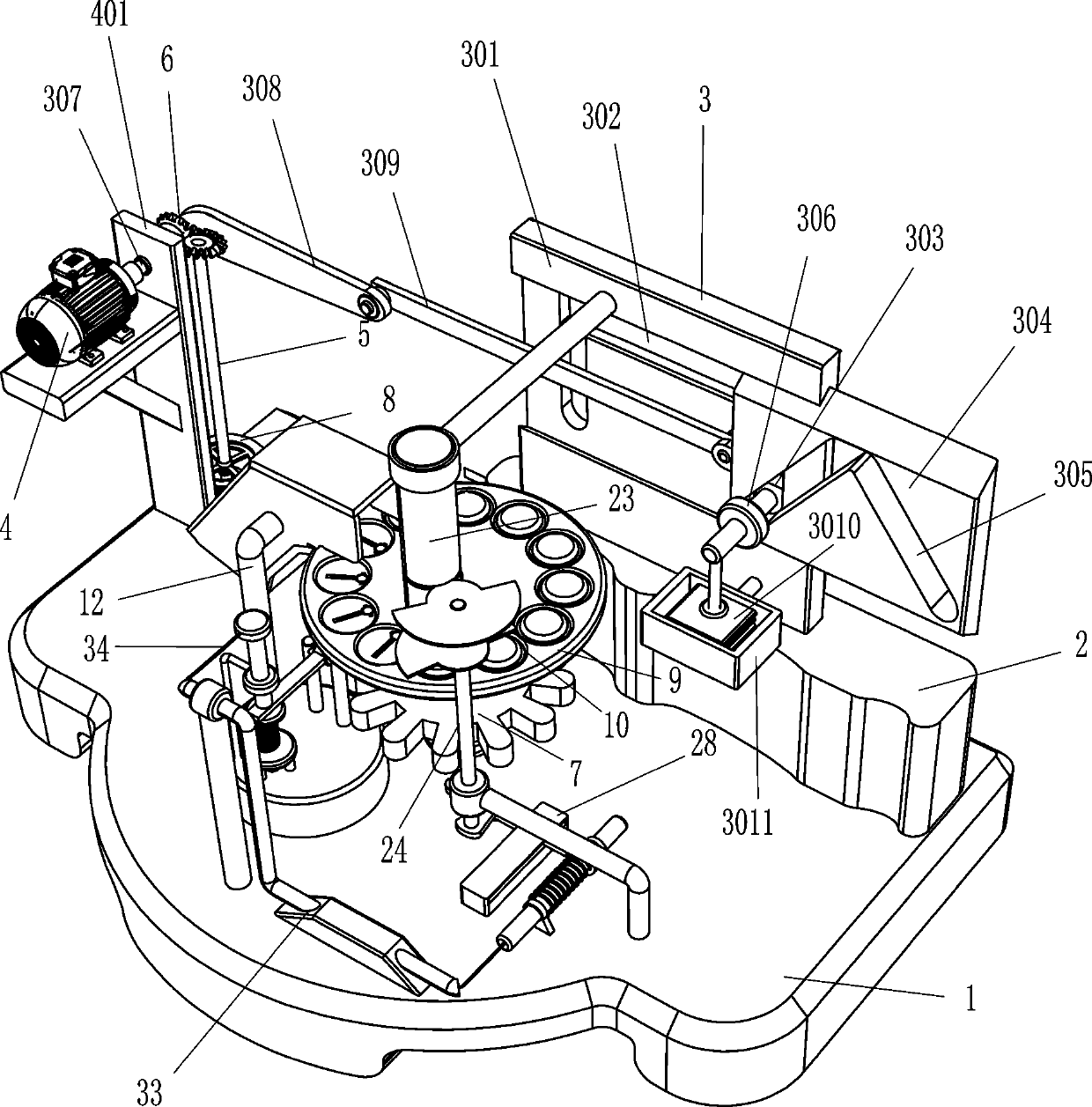

[0023] refer to figure 1 and figure 2 , a glutinous rice cake seal equipment, including support base 1, mounting base 2, seal mechanism 3, motor 4, fixed plate 401, first rotating rod 5, bevel gear 6, intermittent rotation mechanism 7, transmission part 8 and rotating disc 9 , the right rear part of the top of the support base 1 is fixedly connected with the mounting base 2, the left rear part of the top of the support base 1 is fixedly connected with a fixed plate 401, and a seal mechanism 3 is arranged between the upper part of the fixed plate 401 and the top of the mounting base 2, and the fixed plate A motor 4 is installed on the upper part of the front side of 401, the output shaft of the motor 4 is connected with the seal mechanism 3, and the top left rear part of the support base 1 is connected with the first rotating rod 5 in a rotating manner, and the first rotating rod 5 is located at the rear side of the fixed plate 401 , the top of the first rotating rod 5 and th...

Embodiment 2

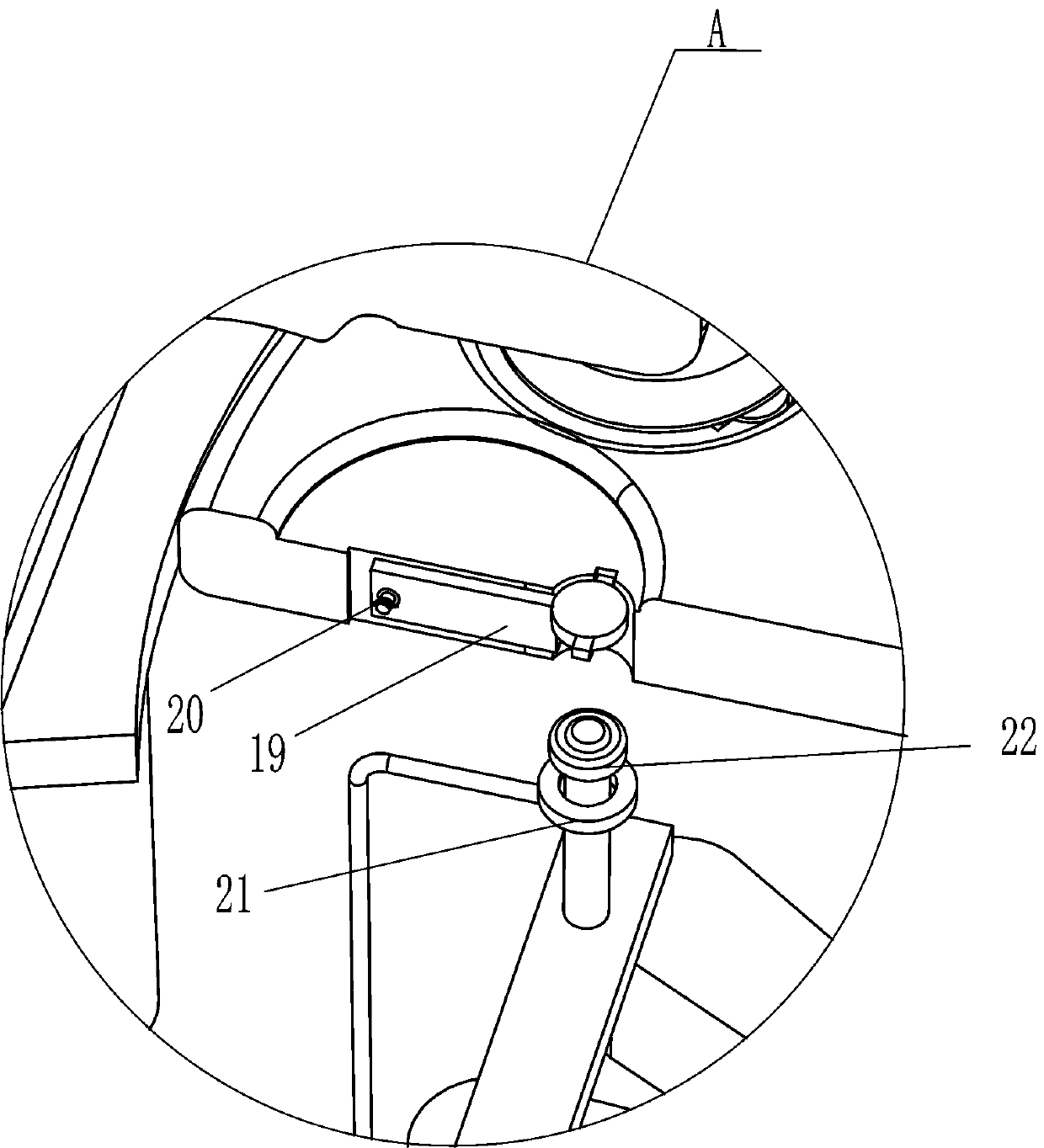

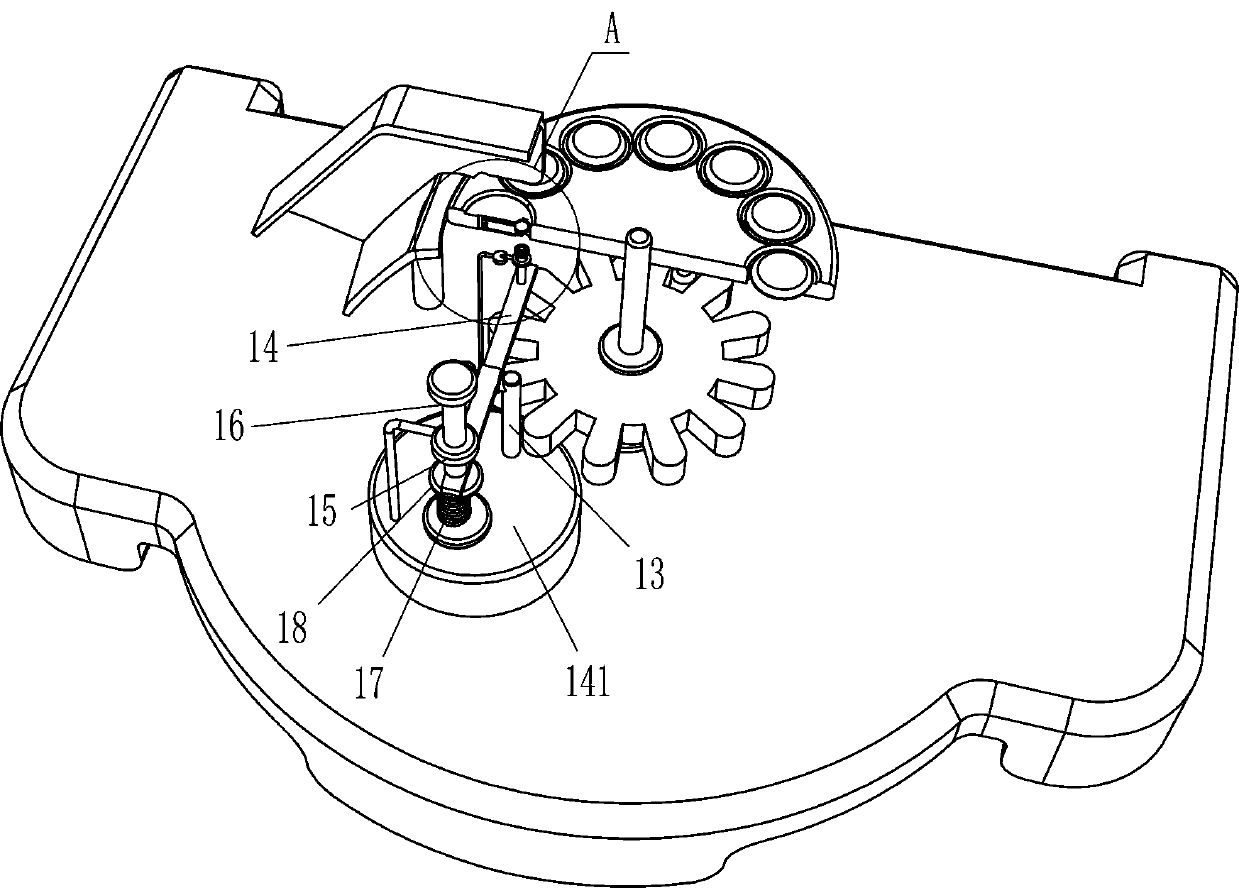

[0030] refer to figure 1 , image 3 and Figure 5 Compared with Embodiment 1, the main difference of this embodiment is that this embodiment also includes a blanking frame 12, a support frame 13, a swing plate 14, a frame body 141, a guide sleeve 15, a push rod 16, and a first spring 17. , movable rod 18, pusher plate 19, torsion spring 20, limit ring 21 and push rod 22, the left part of the front side of the top of the support base 1 is fixedly connected with a frame body 141, and the middle of the outer top rear side of the frame body 141 is fixedly connected with a support Frame 13, the swing plate 14 is connected with the rotating type in the middle of the upper part of the support frame 13, and the middle of the left side of the top of the support base 1 is fixedly connected with the limit ring 21, and the sliding type in the limit ring 21 is provided with a push rod 22, and the bottom end of the push rod 22 In contact with the rear side of the top of the swing plate 14...

Embodiment 3

[0033] refer to figure 1 and Figure 4 , the main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, it also includes a placement cylinder 23, a second rotating rod 24, a semi-arc baffle plate 25, a connecting block 26, a guide rod 27, Spacer frame 28, straight orifice plate 29, fixed sleeve 30, slide bar 31, second spring 32, wire conduit 33, backguy 34 and guide sleeve 35, vertical plate 301 front side upper left side are fixedly connected and can make glutinous rice cakes place Placement cylinder 23, placement cylinder 23 is positioned at the upper right front part of rotating disk 9, and placement cylinder 23 cooperates with placement groove 10, and the left part of the top front side of support base 1 is fixedly connected with fixed cover 30, and fixed cover 30 is positioned at frame body 141 front side, A wire conduit 33 is fixedly connected between the right part of the top front side of the support base 1 and the fixed sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com