Film opening device for automatic bagging machine

A bagging machine and automatic technology, applied in packaging and other directions, can solve the problems of high labor intensity, low work efficiency, and easy safety accidents, and achieve the effect of reducing labor costs and improving bagging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

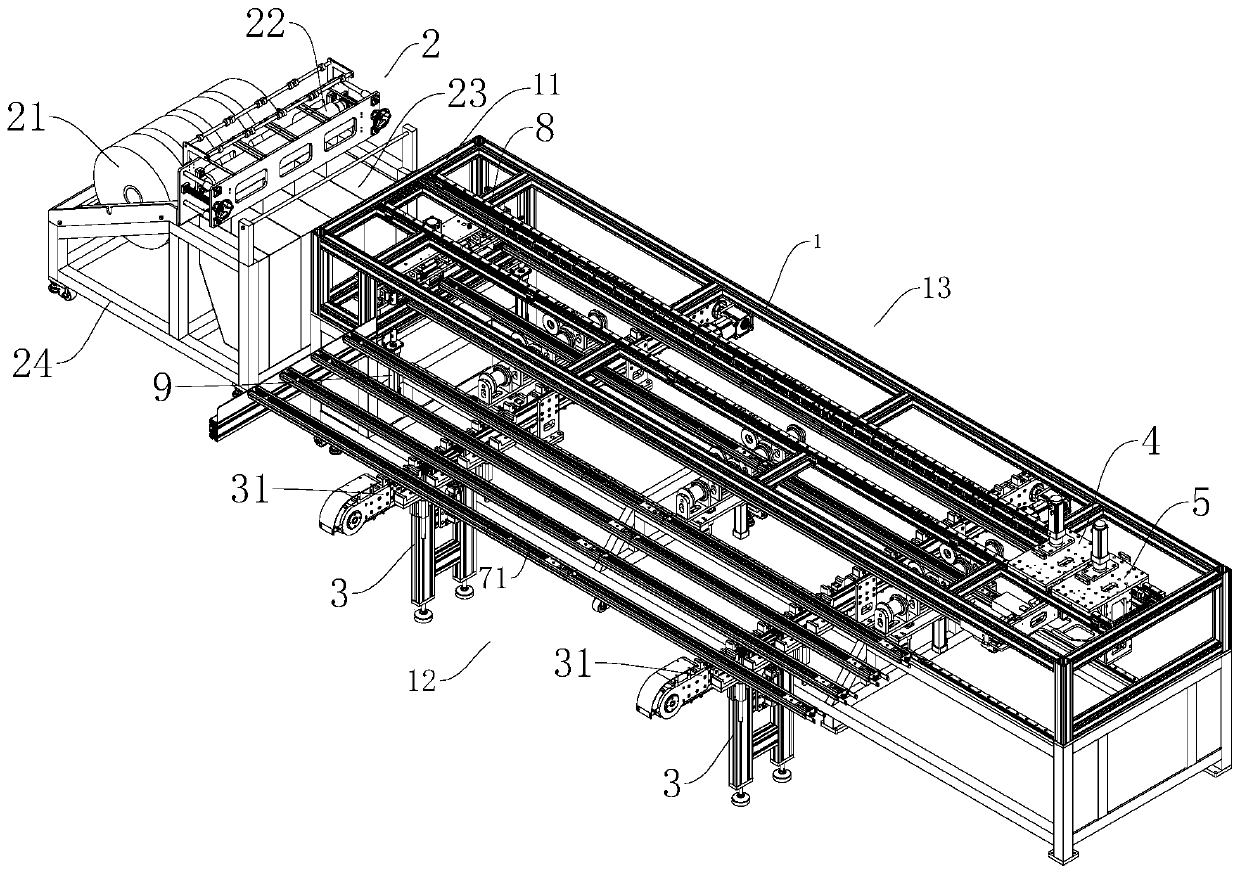

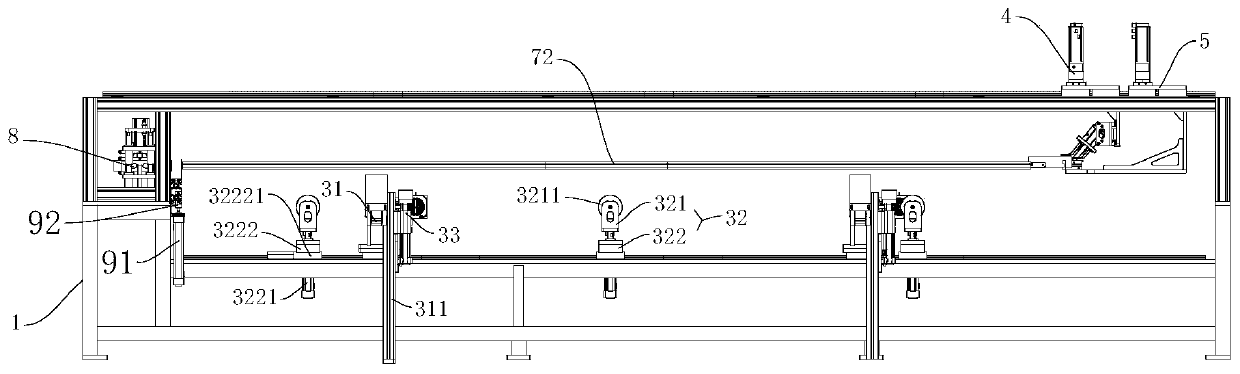

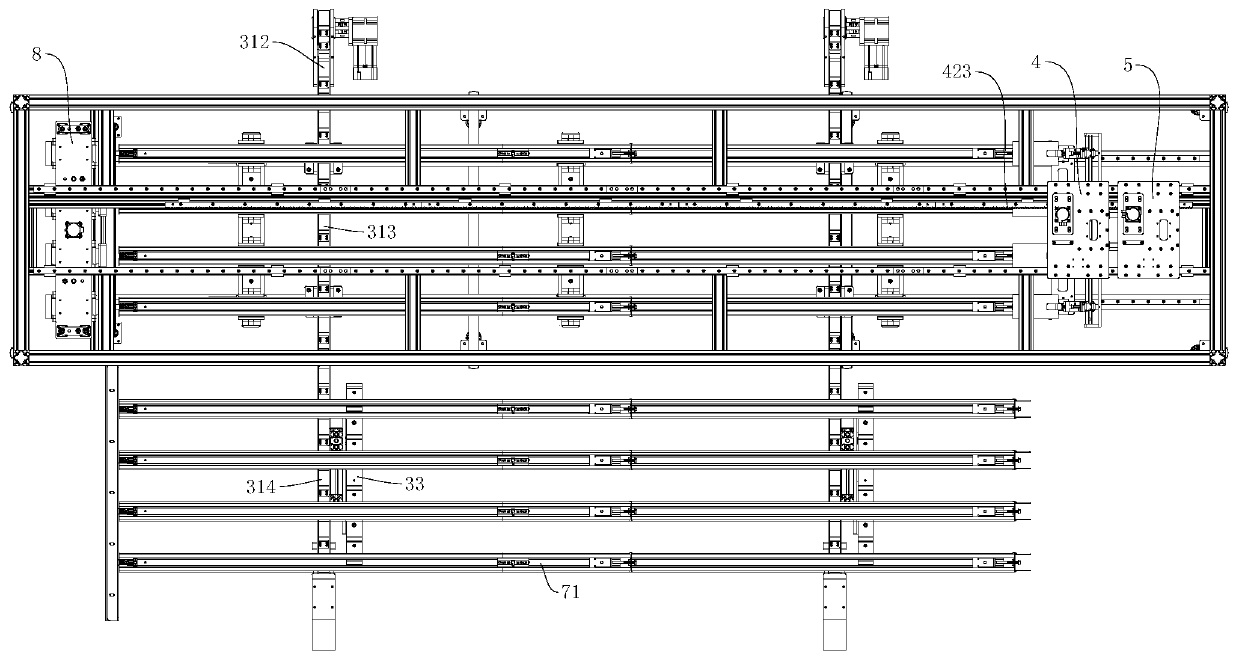

[0033] combine Figure 1 to Figure 14 The film stretching device of the automatic bagging machine of the present invention will be further described.

[0034] An automatic bagging machine is characterized in that it includes a frame 1, a film feeding device 2, a film stretching device 8, a film pulling device 4, a profile positioning device 5, a profile feeding device 3 and a film cutting device 9. Frame 1 is a cuboid structure, which is formed by splicing multiple supporting beams; one end of frame 1 is the film bag feeding end 11, and the film bag is fed into frame 1; Material side 12 and profile discharge side 13. The film feeding device 2 is located at the film bag feeding end 11 of the frame 1, and provides film bags for each device on the frame 1 while storing the film bag roll 21 to perform the bagging work of profiles. The film stretching device 8 is arranged on the film bag feeding end of the frame 1, receives the film bag provided by the film feeding device 2 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com