All-casing-pipe combination

A technology of full casing and casing, applied in casing, drill pipe, drilling equipment, etc., can solve the problems of easy deviation of the rear-inserted steel cage, large deviation of the thickness of the protective layer, and prone to collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments described in the accompanying drawings.

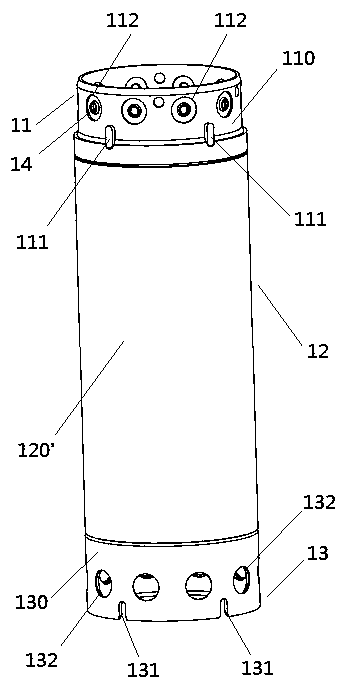

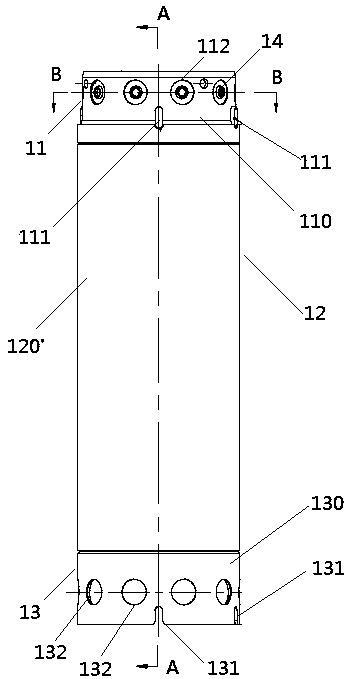

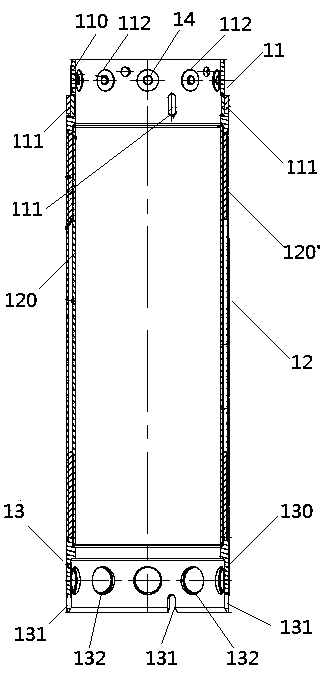

[0027] like Figure 1-6 As shown, a complete sleeve combination is composed of multiple unit sleeves, each unit sleeve includes a sleeve body 12, an outer joint 11, an inner joint 13, a locking disc 14, and a locking cover 15, and the sleeve body 12 includes an inner tube body 120 and outer tube body 120'; the outer joint 11 includes an outer joint ring 110, a positioning block 111 located at the lower end of the outer wall of the outer joint ring and a plurality of outer head counterbores 112 arranged on the outer joint ring; the inner joint 13 includes an inner joint ring 130, the positioning groove 131 located at the lower end of the outer wall of the inner joint ring and a plurality of inner head counterbores 132 arranged on the inner joint ring; the locking disc 14 includes a disc seat 141 and a central inner screw hole 145; the lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com