Pipe shed construction method for weak surrounding rock section of tunnel portal

A technology with weak surrounding rocks and construction methods, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problem that the tail of the pipe shed falls into the excavation contour line, the trajectory of the pipe shed drilling process cannot be grasped, and the tunnel excavation surrounding For problems such as grouting and consolidation, the effect of excavation deformation is obvious, the drilling process is precise, and the water consumption is less.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

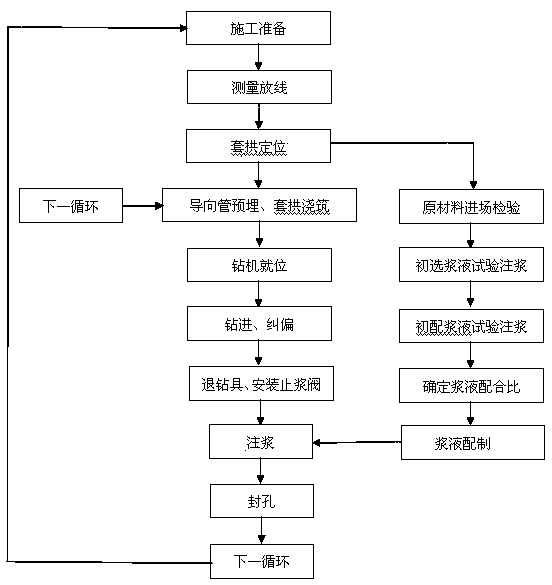

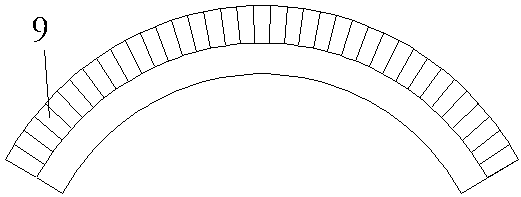

[0026] Embodiment 1: A method for constructing an ultra-long pipe shed in the weak surrounding rock section of a tunnel entrance, the steps of the method are: step 1, construction preparation; step 2, measurement and setting out; step 3, construction of guide wall 9; The surface of the sub-face and the side and the upward slope are closed; step 5, the drilling machine is in place; step 6, drilling; step 7, the drilling tool is withdrawn; step 8, grouting; step 9, sealing the hole.

[0027] In Step 3, the inner arch frame of the guide wall 9 is firstly installed; secondly, the guide pipe is pre-embedded, and the guide pipe and the arch frame are firmly welded; finally, the guide wall 9 is molded and concrete is poured.

[0028] In step 4, use sprayed concrete to encapsulate, with a thickness ≥ 20cm.

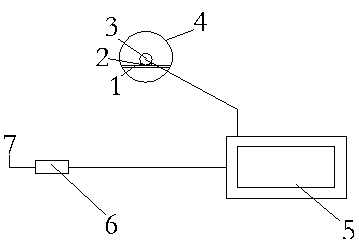

[0029] Step 6: (1) Drill pipe processing: the rod body is a section of 8m, one end of which is threaded inside the car, and one end is threaded outside the car, and local welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com