Motor concentricity comparison method, system and device and computer readable storage medium

A storage medium and comparison system technology, applied in the field of motor measurement, can solve problems such as the inability to quickly compare the concentricity of the AC motor stator and rotor, and achieve the effects of small external influence factors, improved measurement accuracy, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

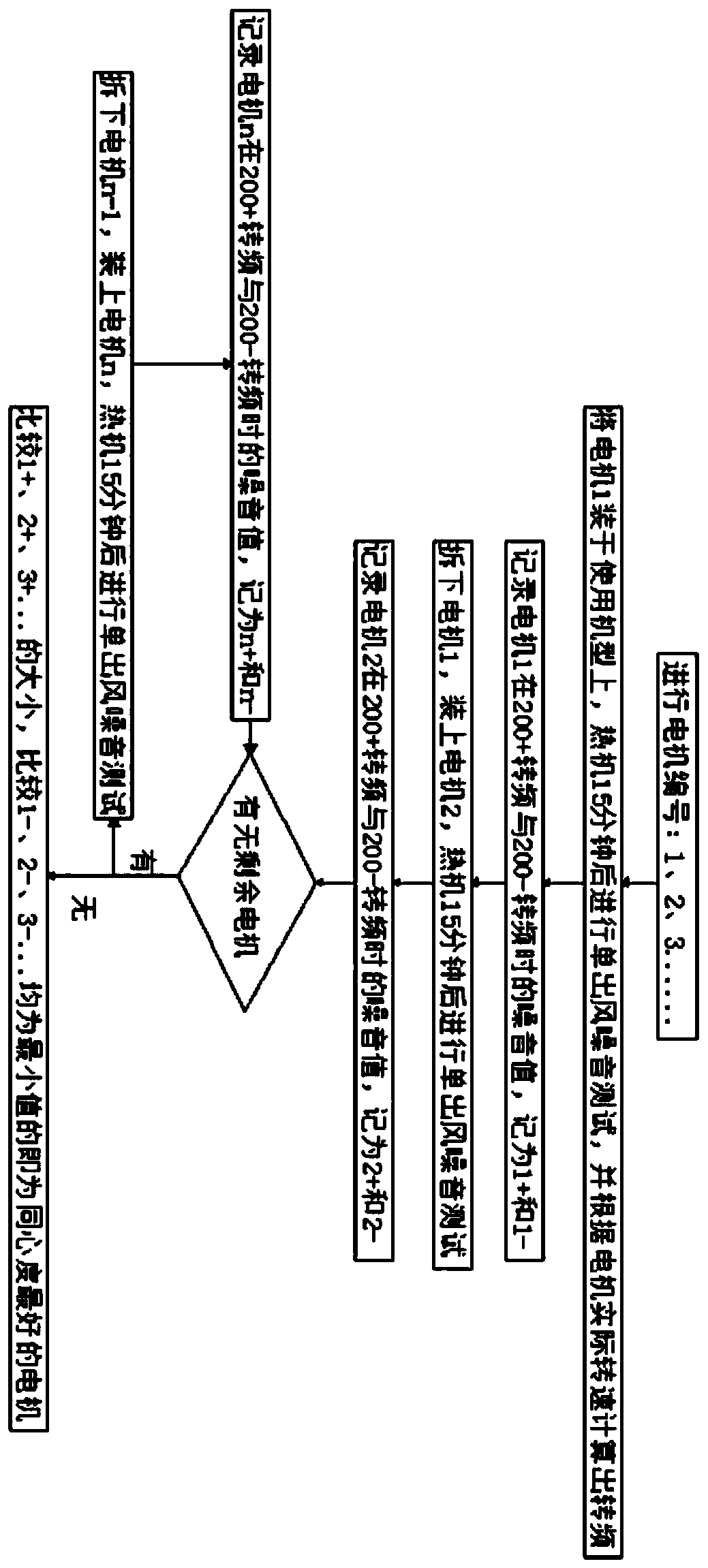

[0036] Such as figure 1 As shown, a comparison method of motor concentricity, including steps:

[0037] S1, number all motors: 1, 2, 3...;

[0038] S2, respectively install motors 1, 2, 3... on the used model, conduct a single-outlet wind noise test, and calculate the rotation frequency according to the actual rotation speed of the motor, and the rotation frequency = the actual rotation speed of the motor / 60;

[0039] S3, through the noise tester to collect the noise of the motors 1, 2, 3... at different rotation frequencies;

[0040] S4, compare the noise levels of motors 1, 2, 3... at special rotation frequency points, and sort them. The motor with the lowest noise value is the motor with the best concentricity of the stator and rotor.

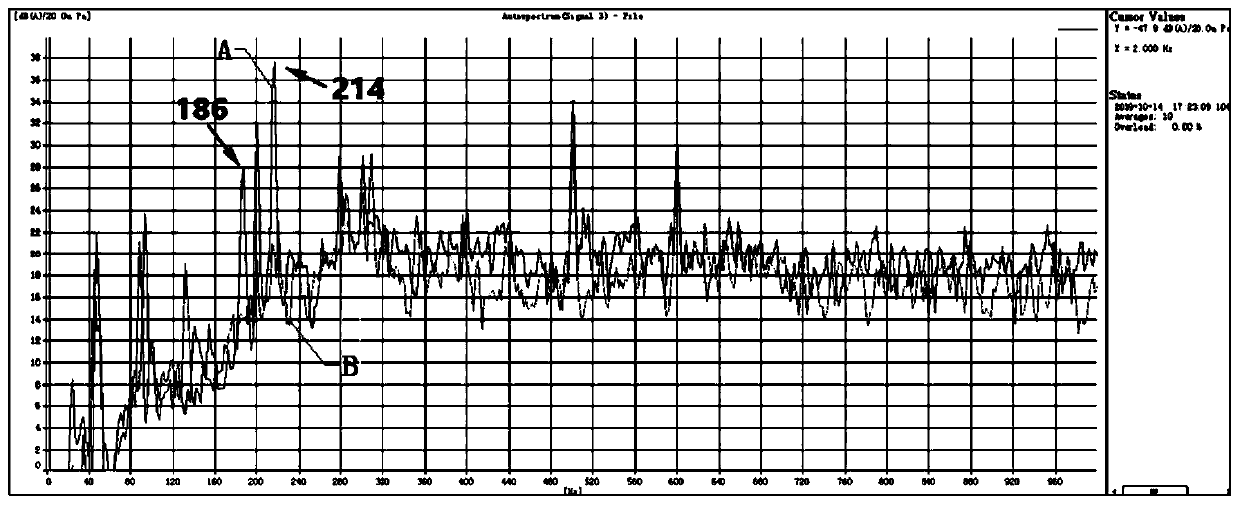

[0041] Further, the special frequency point is the point at which the stator and rotor of the motor generate noise peaks. At the special frequency point, few other components of the motor produce peak effects, which greatly avoids noise ge...

Embodiment 2

[0046] A method for comparing motor concentricity, comprising steps:

[0047] S1, number all motors: 1, 2, 3...;

[0048] S2, respectively install motors 1, 2, 3... on the used model, conduct a single-outlet wind noise test, and calculate the rotation frequency according to the actual rotation speed of the motor, and the rotation frequency = the actual rotation speed of the motor / 60;

[0049] S3, through the noise tester to collect the noise of the motors 1, 2, 3... at different rotation frequencies;

[0050] S4, compare the noise levels of motors 1, 2, 3... at two special rotation frequency points, and sort them. The numbered motor whose noise reaches the minimum value at the same time is the motor with the best concentricity of the stator and rotor.

[0051] Further, the special frequency point is the point at which the stator and rotor of the motor generate noise peaks. At the special frequency point, few other components of the motor produce peak effects, which greatly avoi...

Embodiment 3

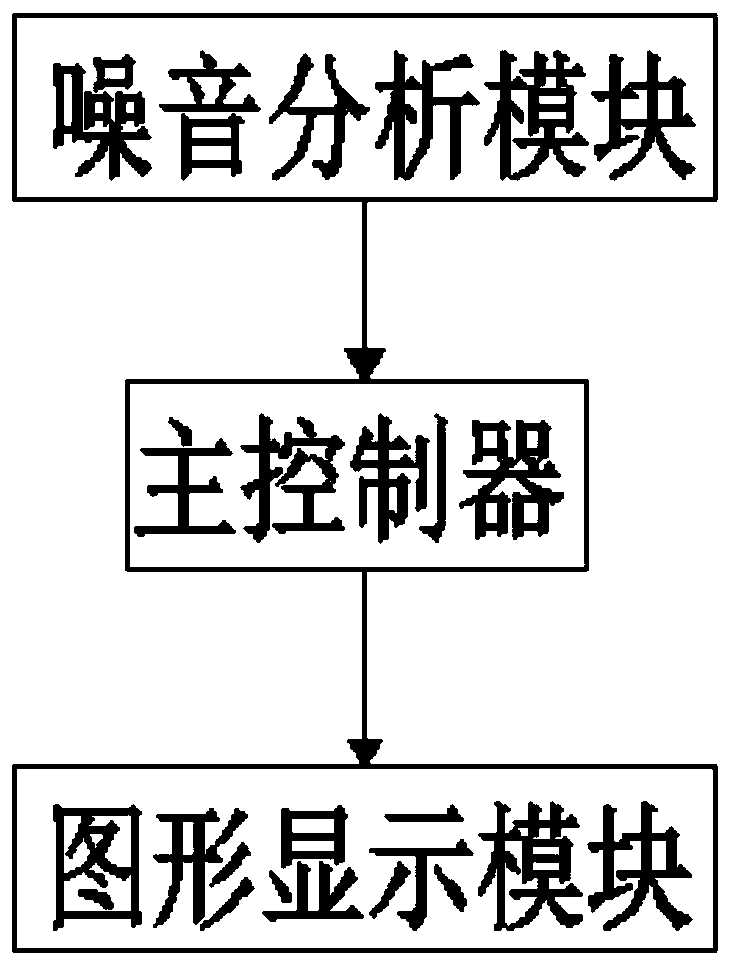

[0057] Such as figure 2 As shown, a comparison system of motor concentricity, including:

[0058] A noise analysis module, the noise analysis module can record the noise of the motors 1, 2, 3... at different rotation frequencies, and transmit the recorded data to the main controller.

[0059] A main controller, the main controller can fit the noise data of the motors 1, 2, 3... in the noise analysis module at different rotational frequencies.

[0060] A graphic display module, the graphic display module can display the fitting result of the main controller, and can intuitively compare the magnitude of the noise generated by the motors 1, 2, 3... under different rotational frequencies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com