Residual stress detection method for aluminum product

A residual stress and detection method technology, applied in force/torque/work measuring instruments, measuring devices, analysis materials, etc., can solve the problems of many interference factors and low data reliability, reduce the influence of external factors and improve detection The effect of improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

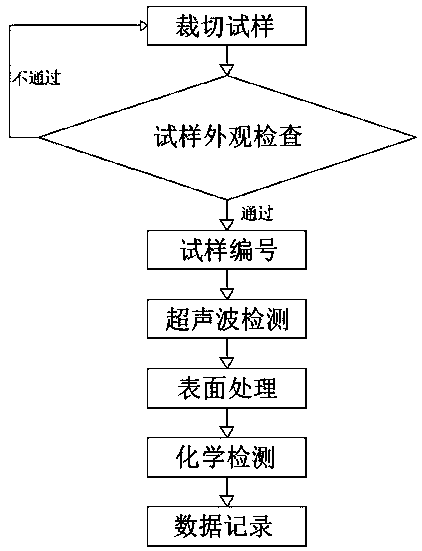

[0023] refer to figure 1 , a method for detecting residual stress of aluminum products, comprising the following steps:

[0024] S1: Cut the sample, cut and sample at both ends and the middle part of the tested sample;

[0025] S2: Appearance inspection of the sample. When in use, the laser level detection device detects the level of the sample, and at the same time records the weight of the sample separately;

[0026] S3: Sample number, different samples are numbered differently and stored in the same location;

[0027] S4: Ultrasonic testing, place the sample to be tested together with the ultrasonic testing equipment in a vacuum box, and perform residual stress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com