Torque motor rotor magnet automatic glue coating assembly system and method

A torque motor and assembly system technology, which is applied to electromechanical devices, electric components, and manufacturing of motor generators, etc., can solve the problems of difficult control of assembly position and strength, low efficiency of manual assembly, and high work intensity, and achieve simple and reliable installation methods. , The assembly position and strength are easy to control, and the amount of glue used is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

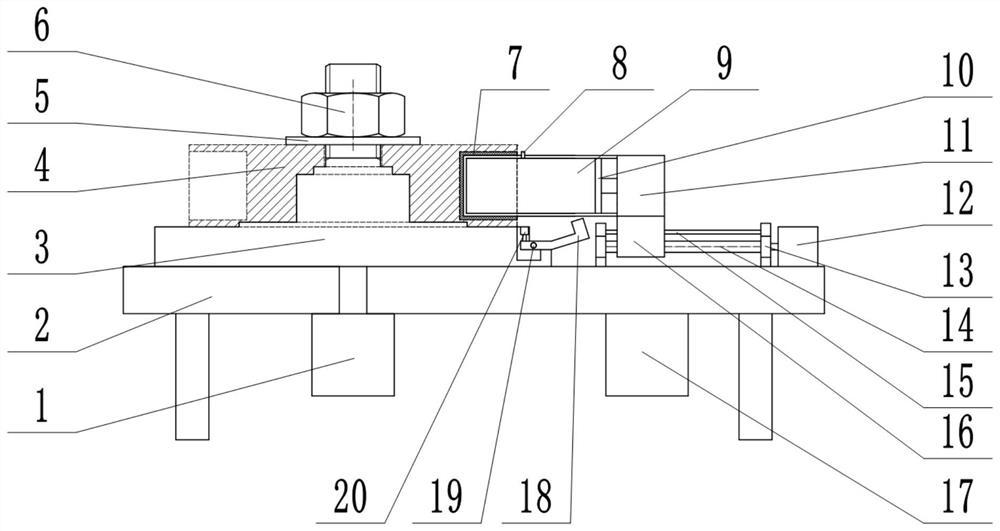

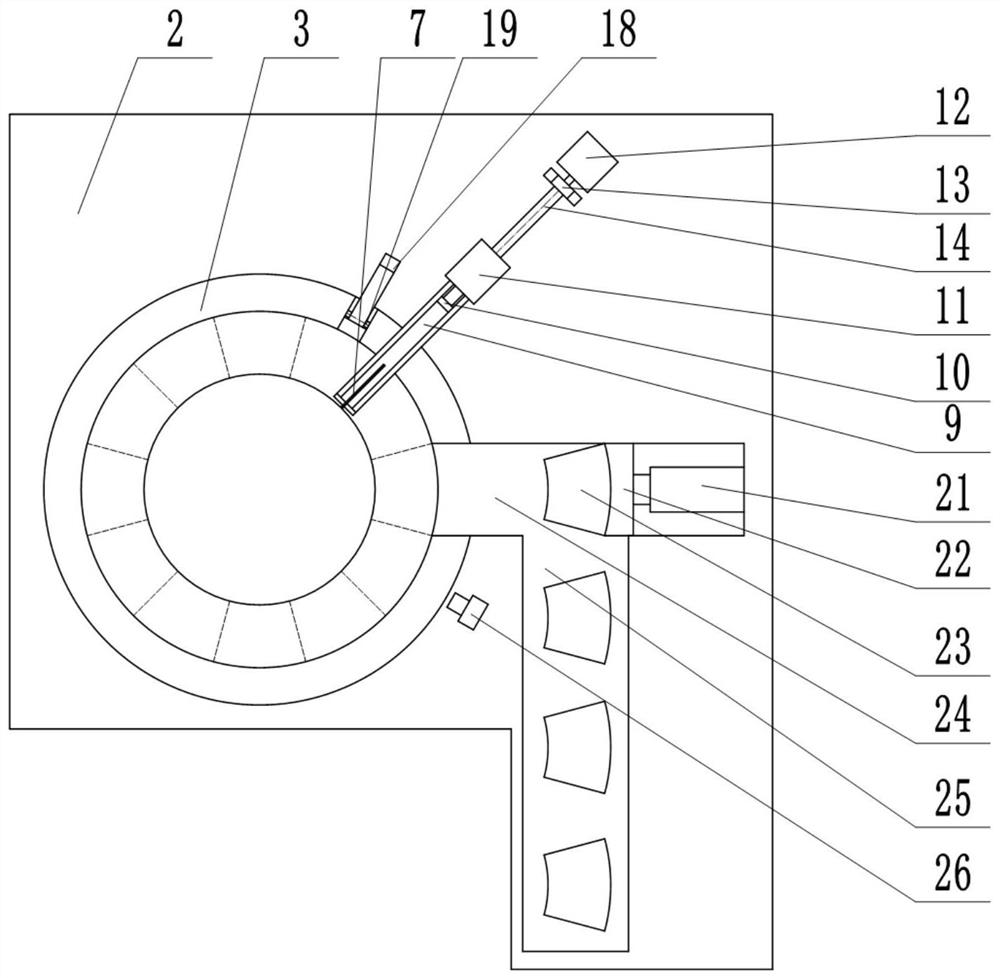

[0036] A typical implementation of the torque motor magnetic steel automatic gluing assembly system of the present disclosure, such as Figure 1-2 , the system mainly includes a frame 2 on which a positioning and rotating device, a gluing device and an automatic assembly device are installed; the positioning and rotating device can realize the positioning and rotation of the rotor yoke, and the gluing device and the automatic assembling device Cooperate to realize the gluing and assembly of the rotor yoke.

[0037] The positioning and rotating device in this embodiment includes a driving member for realizing the rotation of the rotor yoke, and a pressing member for fixing the rotor is arranged above the rotor yoke.

[0038] Specifically, the above-mentioned driving member is preferably a servo motor I1, and the servo motor I1 is fixed below the frame 2 by bolts; a positioning rotating disk 3 is arranged above the frame, and the shape of the positioning rotating disk 3 is not t...

Embodiment 2

[0048] This embodiment also discloses a method for automatically gluing the magnetic steel of a torque motor. The method includes the following steps: first, fix the rotor yoke on the frame, and fix the rotor yoke through the pressing parts; then adjust the gluing brush position, make it contact with the surface of the rotor yoke, control the rotation of the driving part fixed on the frame to realize the glue coating on the surface of the rotor yoke; then when the glued position on the rotor yoke is facing the magnetic steel groove, the rotor yoke stops Rotation; the electromagnet is energized, and the pusher is controlled to push and contact the outer surface of the rotor yoke along the magnetic steel groove to realize the fixation of the magnetic steel, and at the same time change the magnetism of the magnet, return the pusher, and complete the assembly of the first piece of magnetic steel; the first piece After the installed magnetic steel is rotated out of the assembly groo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap