Food emulsifier sterilization equipment

A technology of sterilization equipment and emulsifier, used in food ingredients as emulsifier, food preservation, food science and other directions, can solve the problems of inability to emulsifier sterilization treatment, incomplete sterilization equipment area, poor sterilization effect, etc., to achieve sterilization effect Good, sufficient sterilization, comprehensive effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

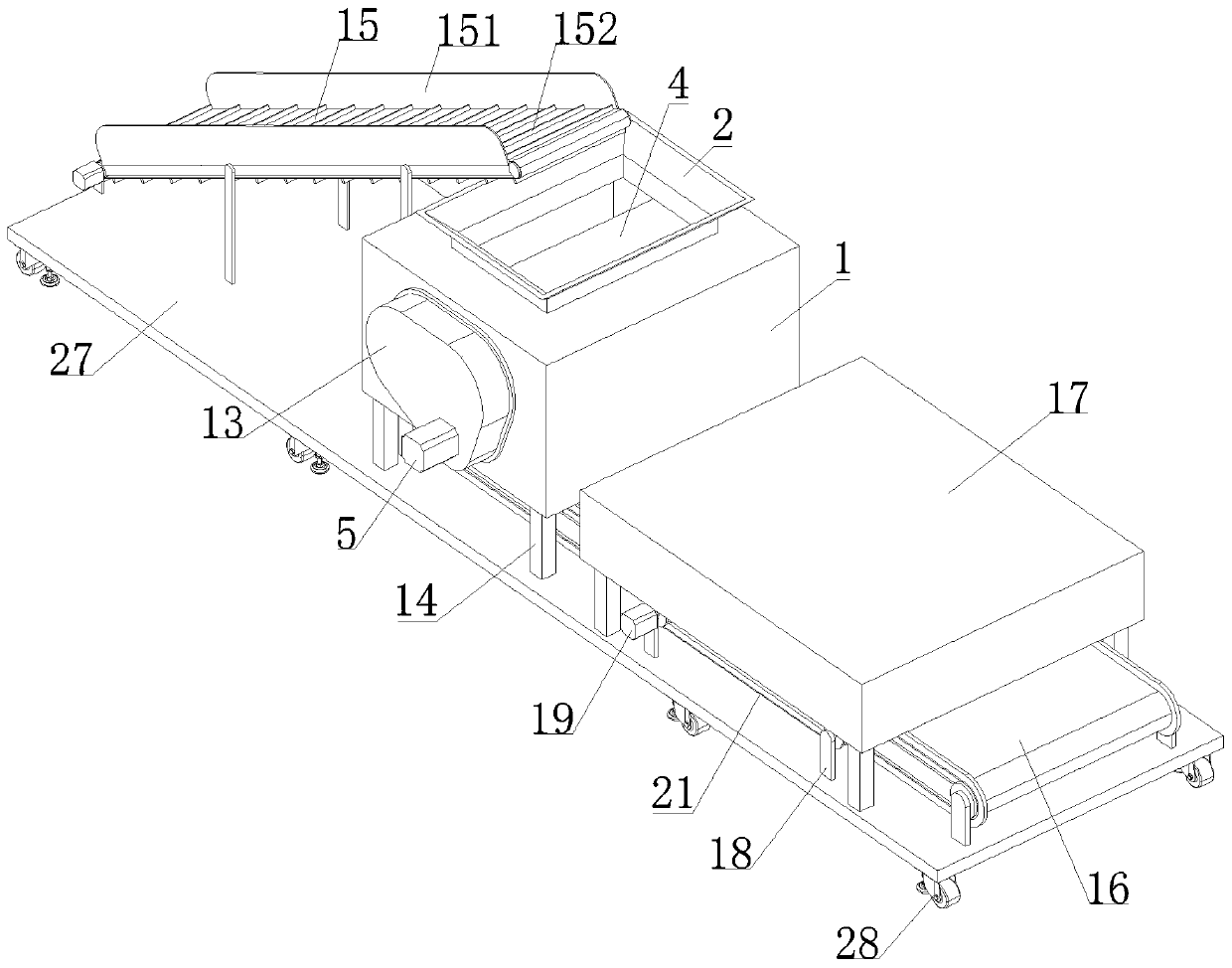

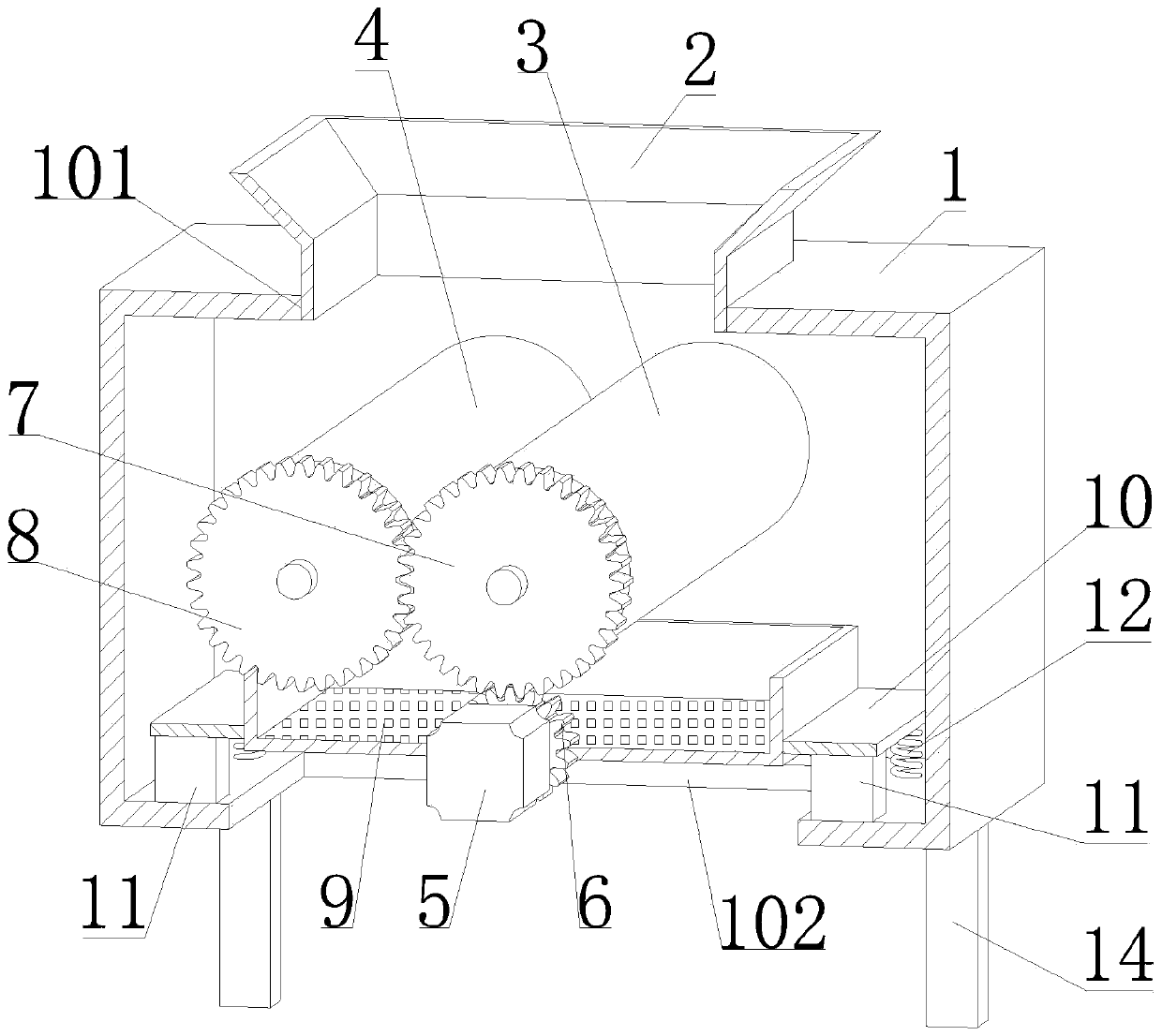

[0022] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: a food emulsifier sterilization equipment, including a bottom plate 27, a crushing box 1, legs 14, a first crushing roller 3 and a second crushing roller 4, and the top of the crushing box 1 is provided with a A feed port 101, the bottom of the crushing box 1 is provided with a discharge port 102, the legs 14 are arranged at the bottom of the crushing box 1, and the bottom of the legs 14 is located on the bottom plate 27, the first crushing roller 3 and the second The crushing rollers 4 are all rotatably connected inside the crushing box 1, and are located between the feed port 101 and the discharge port 102, and the first crushing roller 3 and the second crushing roller 4 are driven to rotate by the first drive assembly; It also includes a conveyor belt feeding mechanism 16, and the conveyor belt feeding mechanism 16 is located on the bottom plate 27, the conveyor belt feedin...

Embodiment 2

[0025] As a preferred solution of Embodiment 1, the first drive assembly includes a gear cover 13, a first motor 5, a driving gear 6, a first driven gear 7 and a second driven gear 8, and the gear cover 13 is fixed It is arranged on one side of the crushing box 1, the first motor 5 is welded on the gear cover 13, the driving gear 6 is fixedly arranged on the output end of the first motor 5, and the first driven gear 7 is connected to the first The pulverizing roller 3 is coaxially fixed, and is rotatably connected inside the pulverizing box 1, the first driven gear 7 is meshed with the driving gear 6, the second driven gear 8 is coaxially fixed with the second pulverizing roller 4, and The first driven gear 7 is in mesh with the second driven gear 8 and is rotatably connected inside the crushing box 1 .

[0026] Working process: the output end of the first motor 5 drives the driving gear 6 to rotate, the driving gear 6 drives the first driven gear 7 to rotate, the first driven...

Embodiment 3

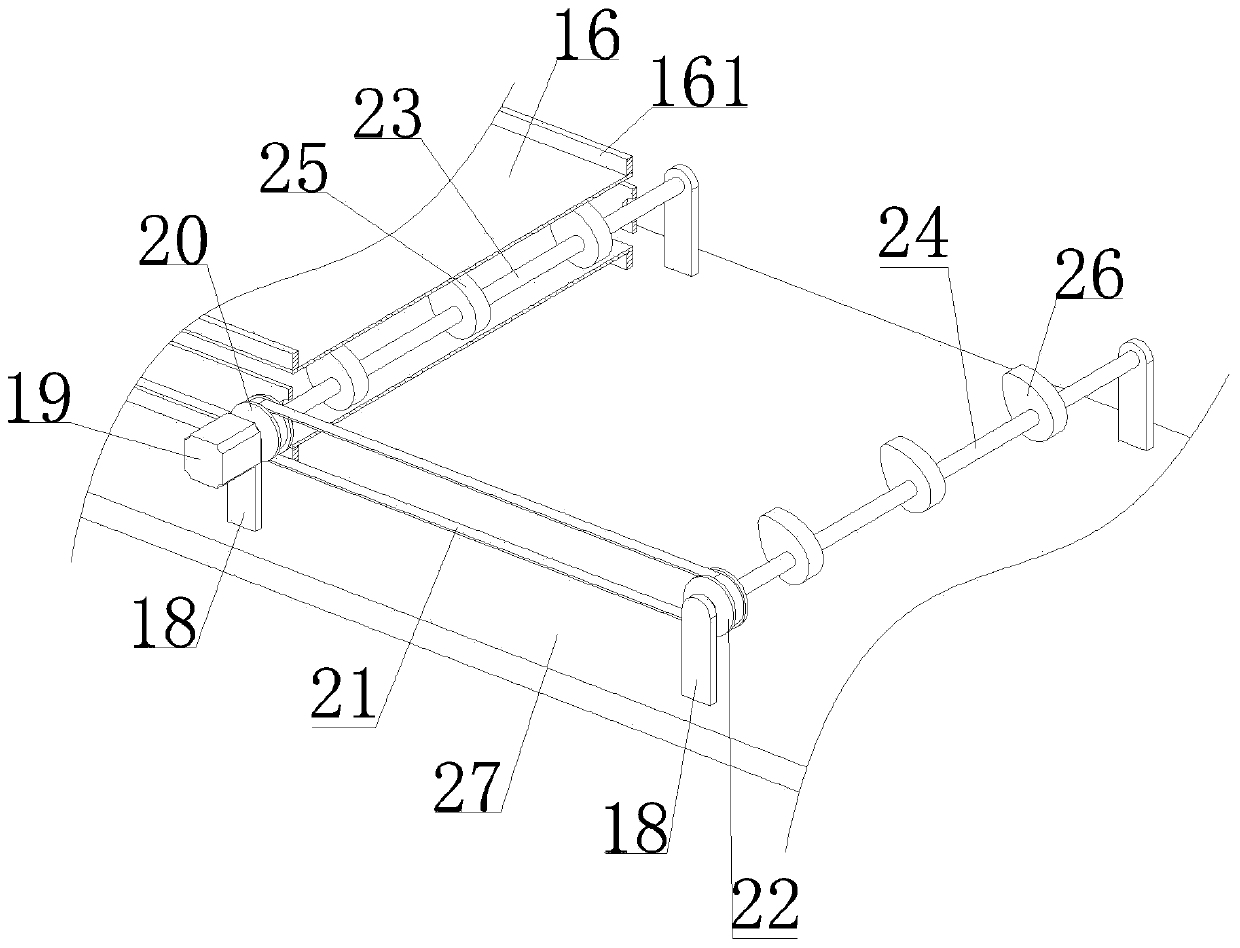

[0028] As yet another preferred solution of the first embodiment, the second drive assembly includes a bracket 18, a second motor 19 and a first installation shaft 23, the bracket 18 is arranged on the base plate 27, and the second motor 19 is arranged On the bracket 18, the first mounting shaft 23 is rotatably connected to the bracket 18, and the first mounting shaft 23 is fixedly connected to the output end of the second motor 19, the first cam 25 is provided with several, and several The first cams 25 are arranged side by side on the first installation shaft 23 .

[0029] Working process: the output end of the second motor 19 drives the first installation shaft 23 to rotate, and the multiple first cams 25 on the first installation shaft 23 can push the conveyor belt to vibrate everywhere, thereby expanding the vibration range and ensuring emulsification everywhere The agent can be vibrated so as to be sterilized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com