Automatic label stripping device

A technology of automatic peeling and labeling, which is applied in the field of printers, can solve the problems that can only be picked up manually and cannot meet the automatic labeling function, and achieve good economic use value, high work efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

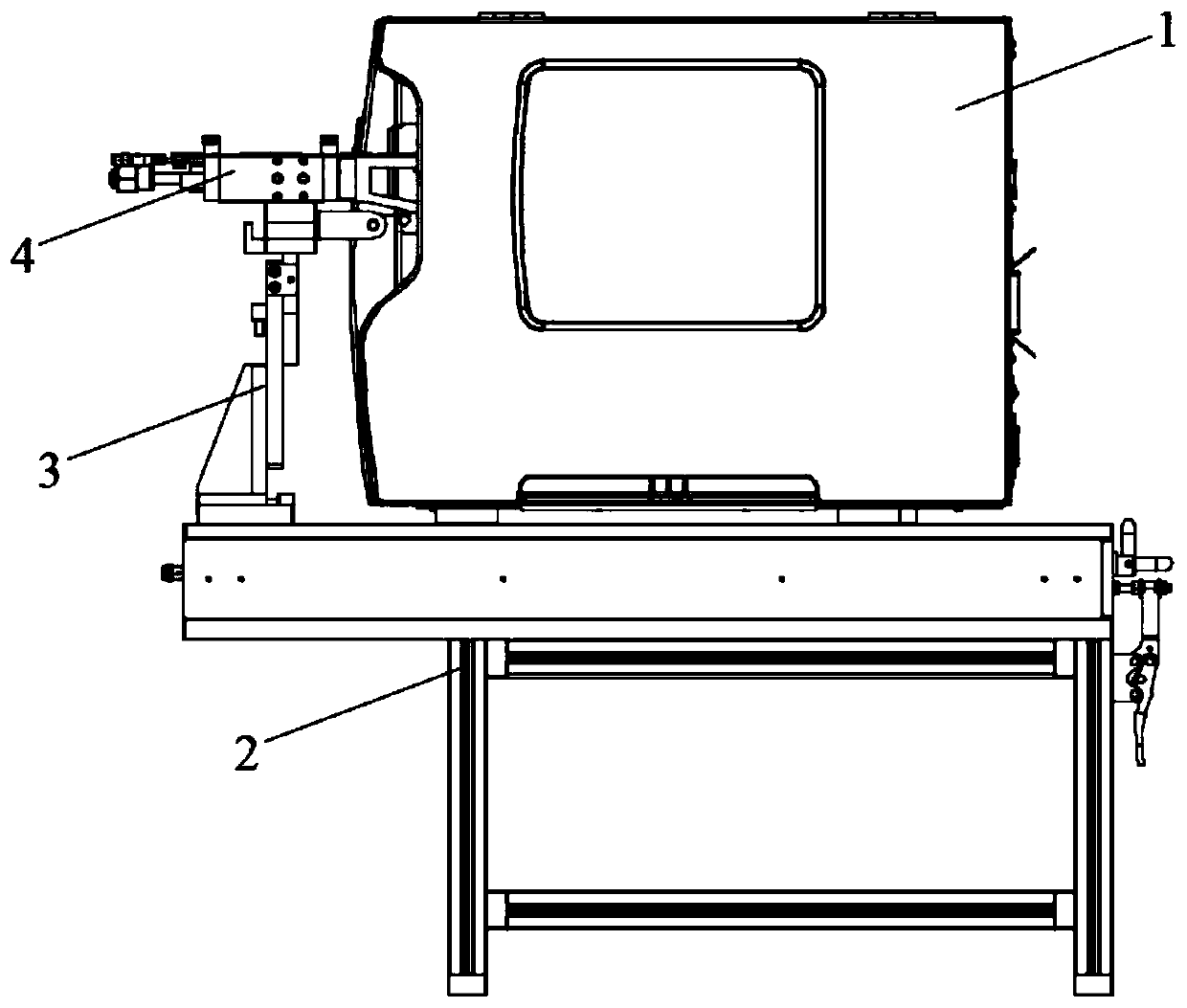

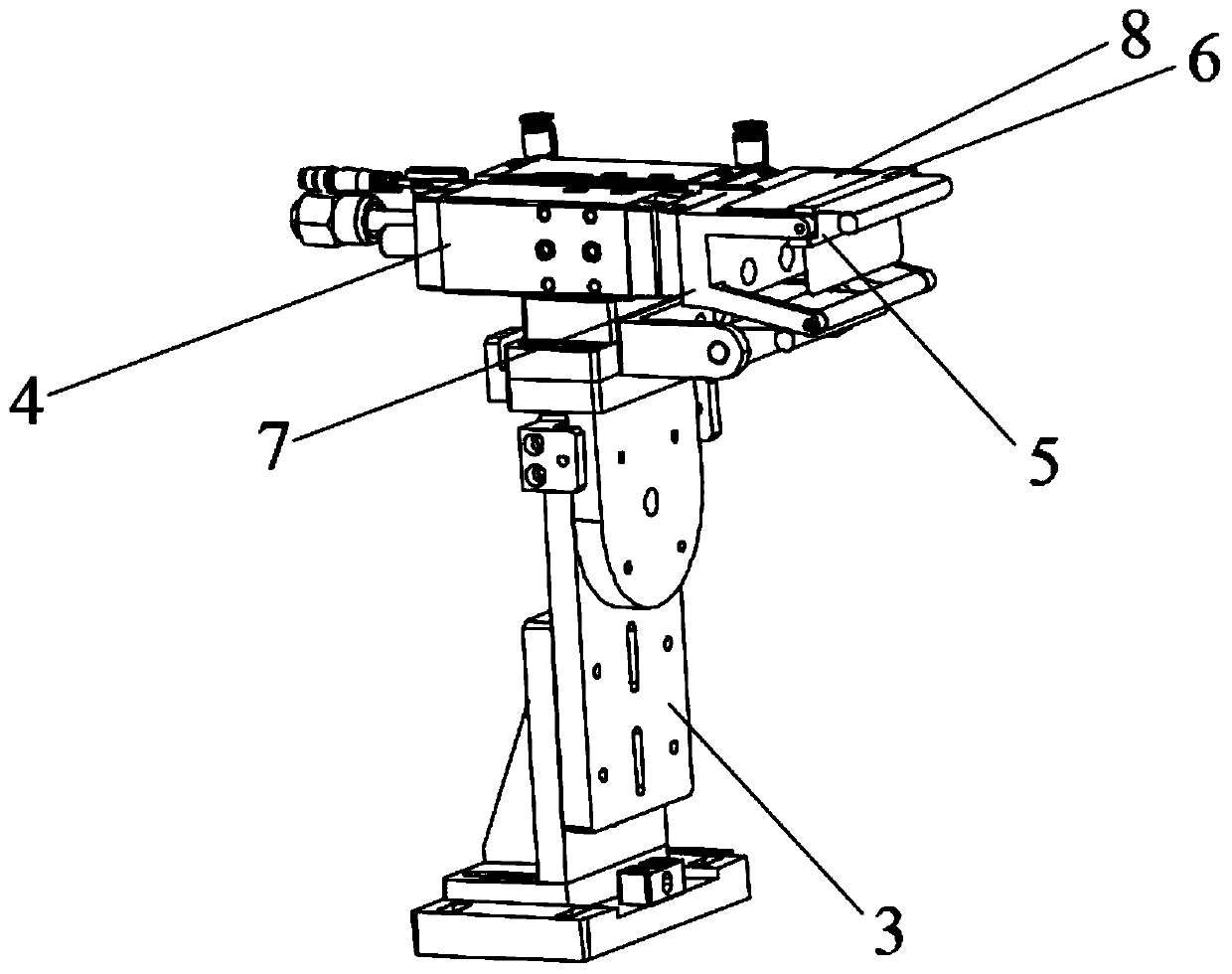

[0011] Such as figure 1 , figure 2 As shown, the present invention includes a printer 1, which also includes a chassis 2, the printer 1 is mounted on the chassis 2, and a peeling module is installed on the chassis 2 at the exit end of the printer 1, and the stripping module includes a The machine base 3 is equipped with a stripping cylinder 4, and the stripping cylinder 4 is connected with a stripping knife assembly. The stripping knife assembly includes a stripping knife seat 5 and a stamping block 6 arranged up and down, between the stripping knife seat 5 and the stamping block 6 There is a height difference for the label paper 8 to pass through. The marking block 6 is provided with a lifting cylinder, and the marking block 6 is connected with the lifting cylinder (not shown in the figure). Through the movement of the lifting cylinder, the pressing block 6 moves downward. Movement is compressed on the stripping knife seat 5.

[0012] The stripping knife assembly also incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com