Intelligent control system and method for scraper reclaimer

An intelligent control system and intelligent control technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems affecting the operation efficiency of the scraper reclaimer, consuming a large working time, continuous reclaiming of difficult material flow, etc., to achieve seamless Humanized operation, improved control accuracy and work efficiency, continuous and stable material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

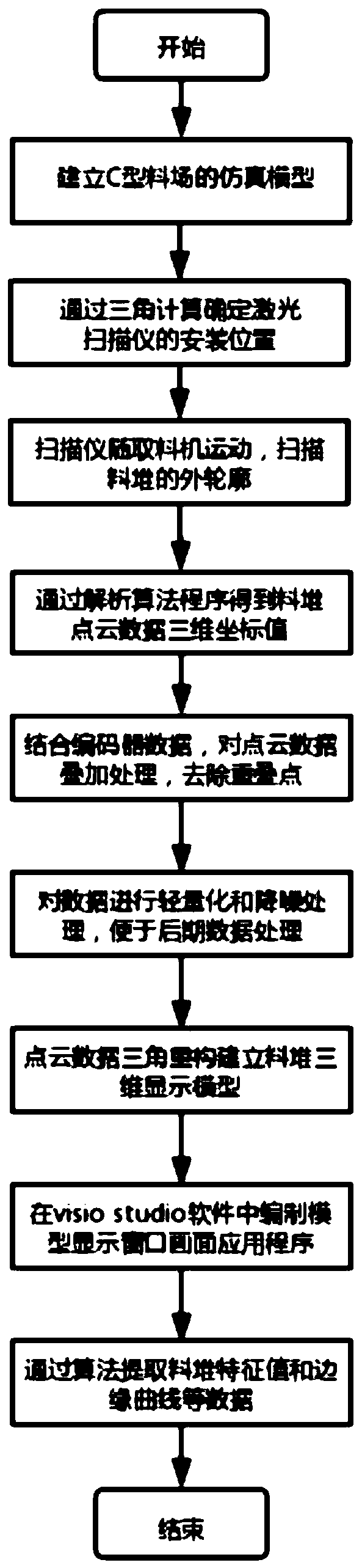

[0030] An intelligent control method for a scraper reclaimer, the specific steps comprising: building a three-dimensional model of a stockpile: obtaining the outer contour data of the stockpile through a 3D laser scanner, establishing a three-dimensional model of the stockpile through a triangular reconstruction algorithm, and extracting the three-dimensional model in the three-dimensional model The highest point curve and bottom edge curve of the stockpile, calculate the slope angle of the stockpile, and the volume parameters of the stockpile;

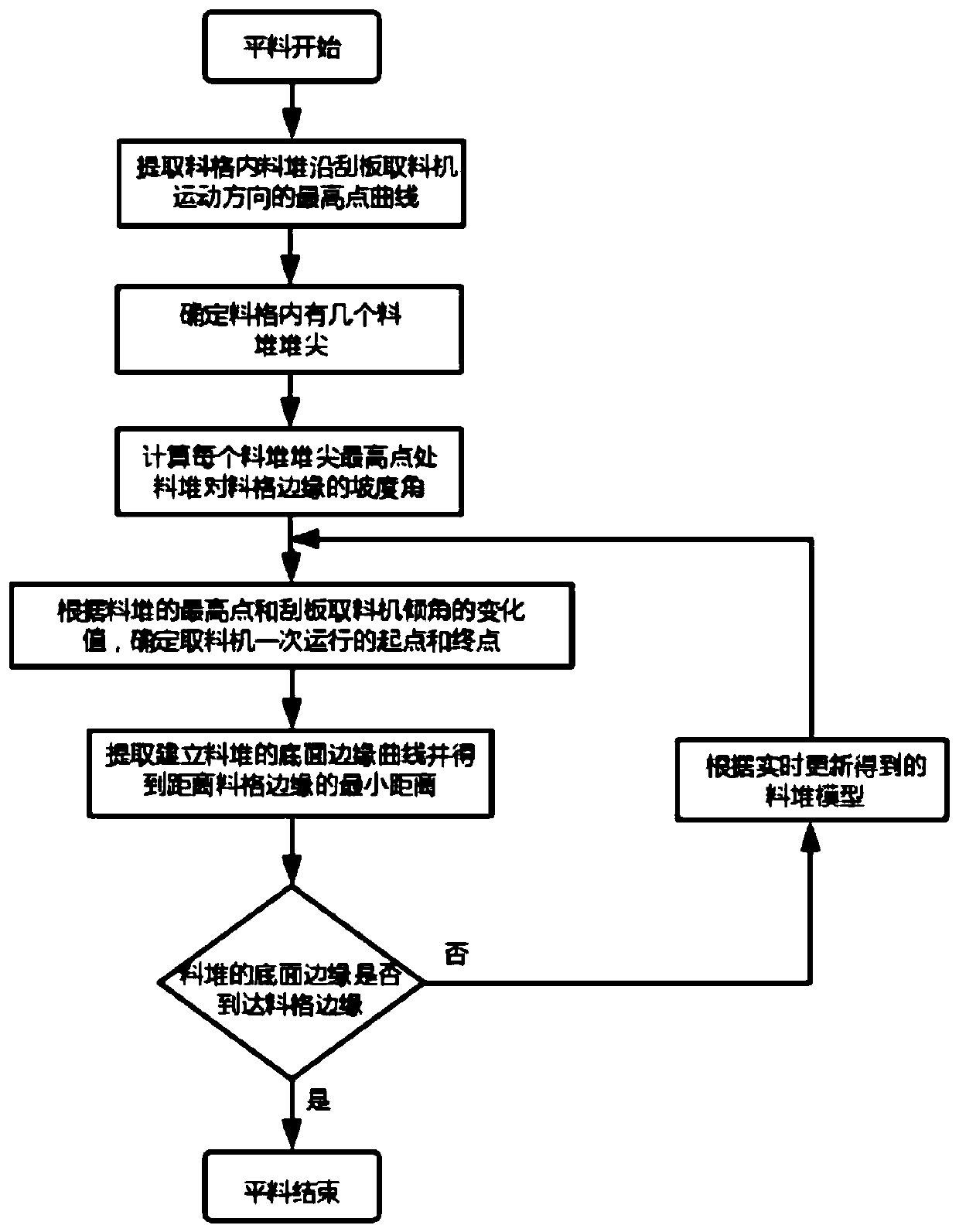

[0031] Intelligent control of flat material process: according to the curve of the highest point and the curve of the bottom edge, set the scraper inclination angle of the scraper reclaimer for flat material, the starting point of flat material and the end point of material flat;

[0032] Intelligent control of the reclaiming process: According to the slope angle of the material pile and the volume of the material pile, the reclaiming ...

Embodiment 2

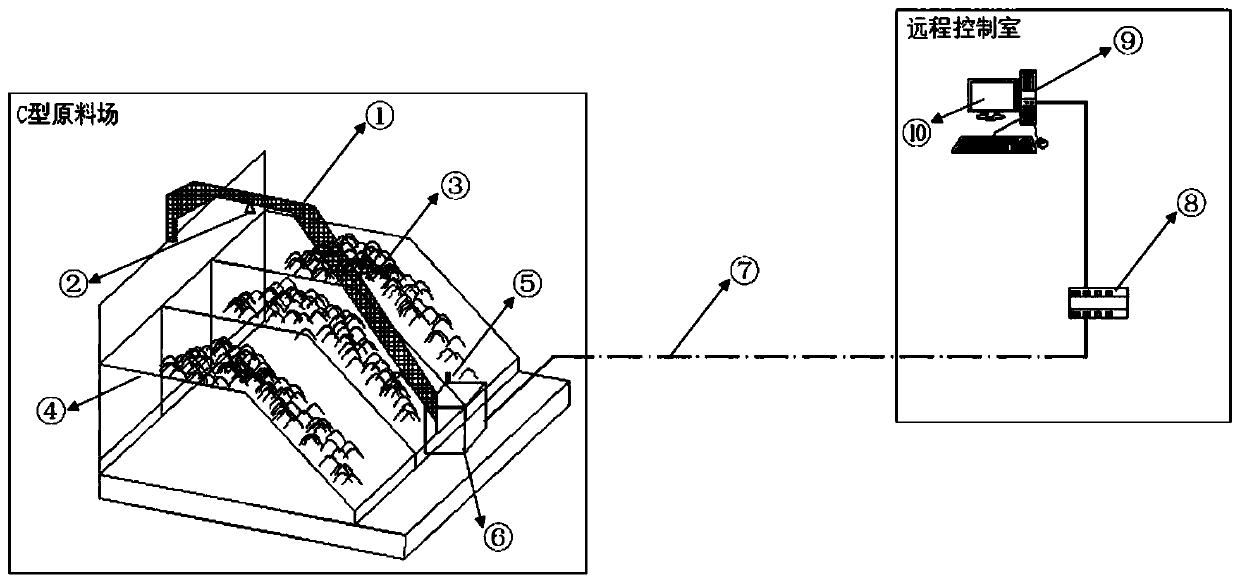

[0057] The invention installs a 3D laser scanner on the scraper reclaimer, scans the stockpile along with the movement of the scraper reclaimer, obtains the point cloud data of the stockpile, and obtains the point cloud data of the stockpile through light weight, de-drying, triangular reconstruction and other data Processing algorithm, reconstructing the model of point cloud data, and establishing its 3D model, the model is updated and displayed on the monitoring computer in the control room in real time, and the highest point of the stockpile, the bottom edge curve of the stockpile, etc. are extracted from the model through the eigenvalue extraction algorithm Data, the data is sent to the PLC system of the reclaimer to control the automatic operation of the scraper reclaimer. The 3D model based on the stockpile can also realize functions such as automatic inventory and intelligent optimization of reclaiming paths, which improves the operating efficiency of the scraper reclaime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com