Ship unloader transportation shipping technology

A ship unloader and process technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of difficult operation, high deviation control accuracy, and the difficulty of freeboard height to meet the requirements of STS roll unloading operation, so as to ensure smooth transfer. , to solve the effect of excessive elevation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

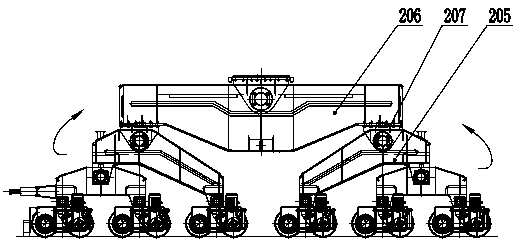

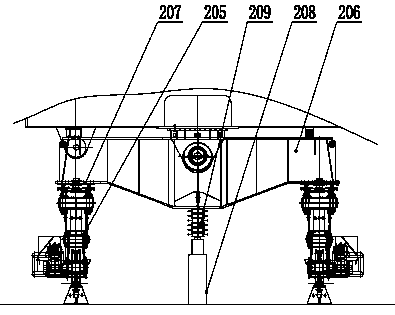

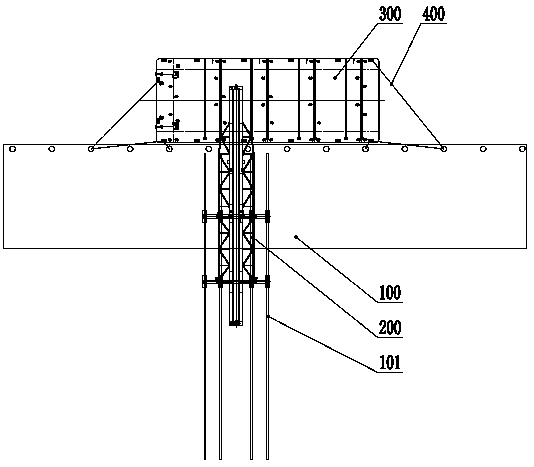

[0061] Below, the present invention will be further described by taking the shipping of the ship unloader (STS) at the port of Mariveles in the Philippines as an example and in conjunction with the accompanying drawings. The unloading port is located in Mariveles Town, Philippines. It is the largest coal unloading berth under construction in the Philippines. The dock elevation is as high as 10 meters, and the tidal range of the port is small, within the range of 0.4-0.8 meters. It is transported by semi-submersible transport ship or barge alone. , the height of its freeboard cannot meet the requirements of STS roll-off operation.

[0062] The ship unloader of this embodiment weighs about 1100 tons. The used barge "Zhenbarge 24" is 100 meters wide, 32 meters wide and 7.5 meters deep, and the semi-submersible transport ship "Tai'ankou" is 36 meters wide. The transportation and delivery process of the ship unloader is as follows.

[0063] Stage one. Shipment, such as Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com