A Combined Structure for Shock Absorption and Collapse Prevention

A technology of combined structure and frame structure, applied in the direction of earthquake resistance, building components, building structure, etc., can solve the problems of falling off parts without protective measures, lack of seismic defense line, low redundancy of frame structure, etc., to achieve broad market application prospects , saving materials, easy to obtain the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

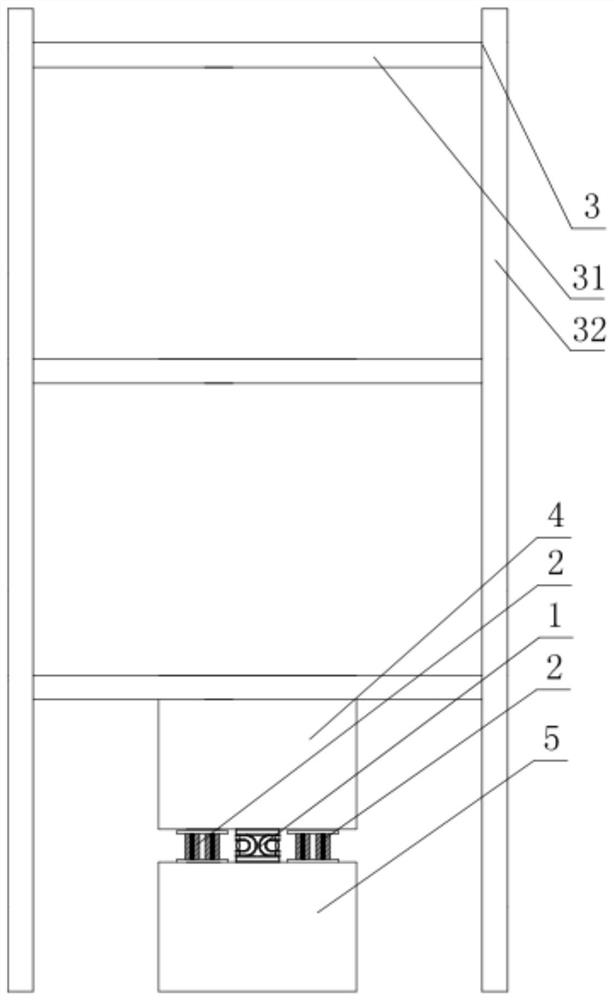

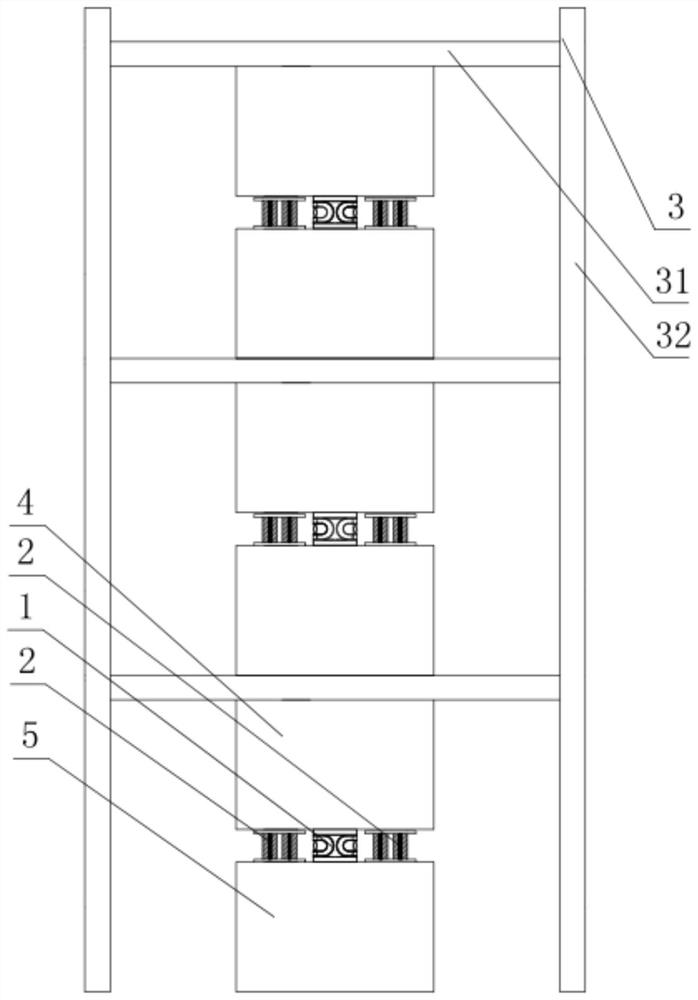

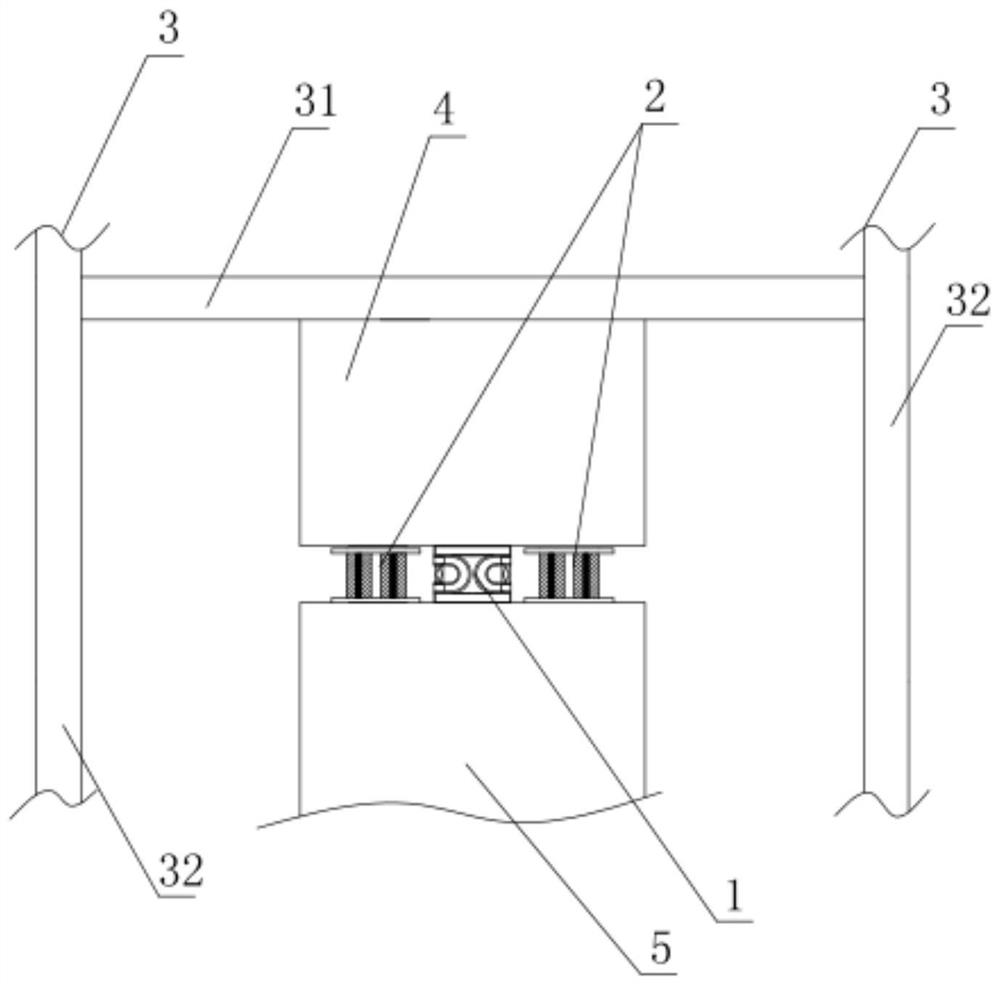

[0046] Such as Figure 1 ~ Figure 3 As shown, a joint structure for shock absorption and anti-collapse described in the present invention, the joint structure includes a step-by-step yield damper 1 and an anti-collapse steel pier 2, and the step-by-step yield damper 1 and the anti-collapse steel pier 2 Both are detachably connected between the upper wall pier 4 and the lower wall pier 5 as lateral force-resisting members in the frame structure 3 through an inter-column type connection, the upper wall pier 4 is connected to the frame beam, and the lower wall pier 5. It is connected with the ground or the floor, and the staged yield damper 1 and the anti-collapse steel pier 2 are connected by inter-column type in the frame structure 3, which improves the redundancy of the main structure and does not affect the normal use function of the main structure. Does not occupy the facade space of the main structure, the frame structure 3 is composed of frame beams 31 and frame columns 32...

Embodiment 2

[0066] There is another structure for reinforcing ribs on the web 22 of the anti-collapse steel pier 2 in Embodiment 1, that is, a number of ribs are welded on both sides of the web 22 of the anti-collapse steel pier 2 to be perpendicular to the web 22 and arranged at intervals. The reinforcement ribs B222 on each web 22 are arranged in the following ways from the front to the rear: the upper end is inclined backward, the upper end is vertically arranged, and the upper end is inclined forward, and the upper end is inclined backward and the upper end is inclined forward. The reinforcing ribs B222 are respectively at an angle of 45° with the reinforcing ribs B vertically arranged in the middle, as Figure 10 shown.

[0067] The vertical reinforcing rib B222 in the middle divides the web 22 into two front and rear regions, which can have a good supporting effect on the vertical concentrated load.

[0068] The reinforcing rib B222 can not only improve the local stability of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com