Ultra-high pressure sealed structure oil cylinder

A sealing structure and ultra-high pressure technology, applied in the field of hydraulic cylinders, can solve problems affecting the service life of seals, affecting the fretting performance of the cylinder, and increasing the frictional resistance of the piston rod movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

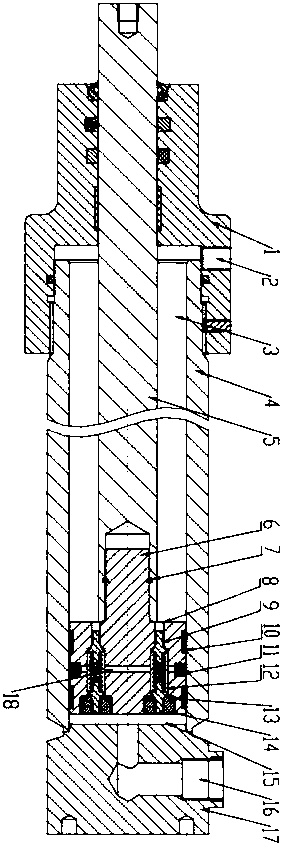

[0022] The specific implementation will be described below in conjunction with the accompanying drawings.

[0023] like figure 1 As shown, the ultra-high pressure sealed structure oil cylinder in this embodiment includes a cylinder body assembly and a piston rod assembly, and the cylinder body assembly is composed of a cylinder head (1), a cylinder (4) and a cylinder head (17), and the piston The rod assembly is composed of a piston (6) and a piston rod (5). One end of the piston rod (5) is connected to the piston (6), and the other end extends from the cylinder head (1) to the outside of the oil cylinder. It is characterized in that the piston ( 6) Divide the inner space of the cylinder assembly into a rod chamber (3) and a rodless chamber (15).

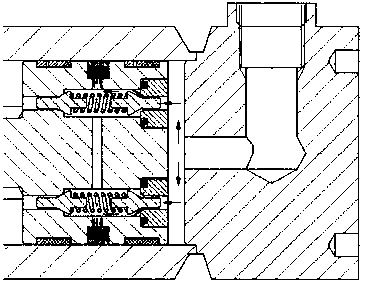

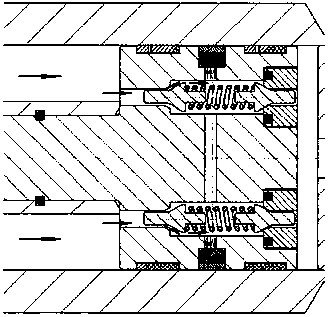

[0024] like Figure 4 As shown, the piston (6) is a stepped shaft. The first stepped shaft has a large diameter and matches with the cylinder (4). Connection; the outer surface of the first stepped shaft circumference is sequenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com