Laser dust detector correction device and correction method

A technology of calibration device and calibration method, which is applied to measurement devices, scientific instruments, analysis of suspensions and porous materials, etc. Scope of production use, reliable performance, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

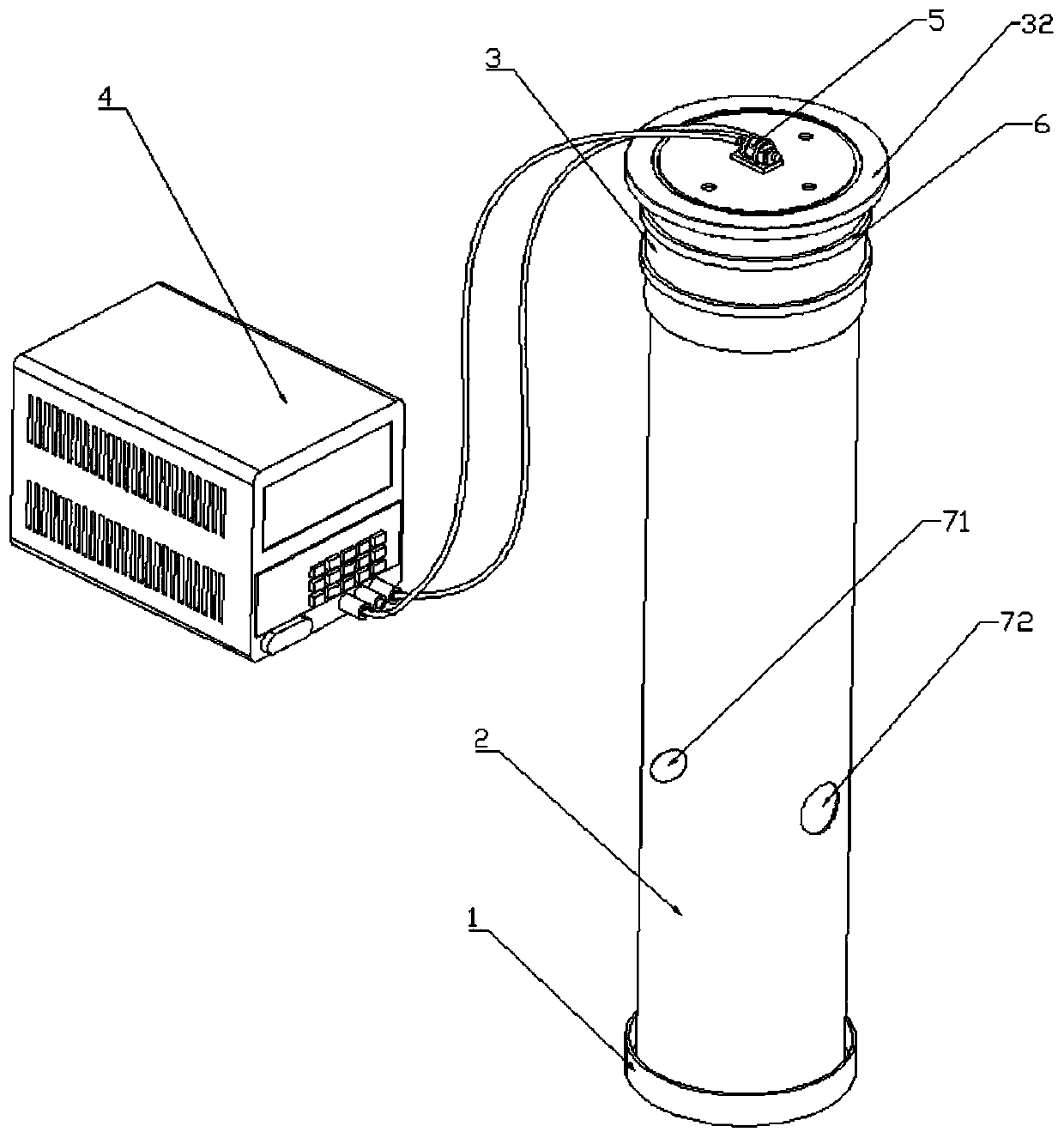

[0020] refer to figure 1 , figure 2 .

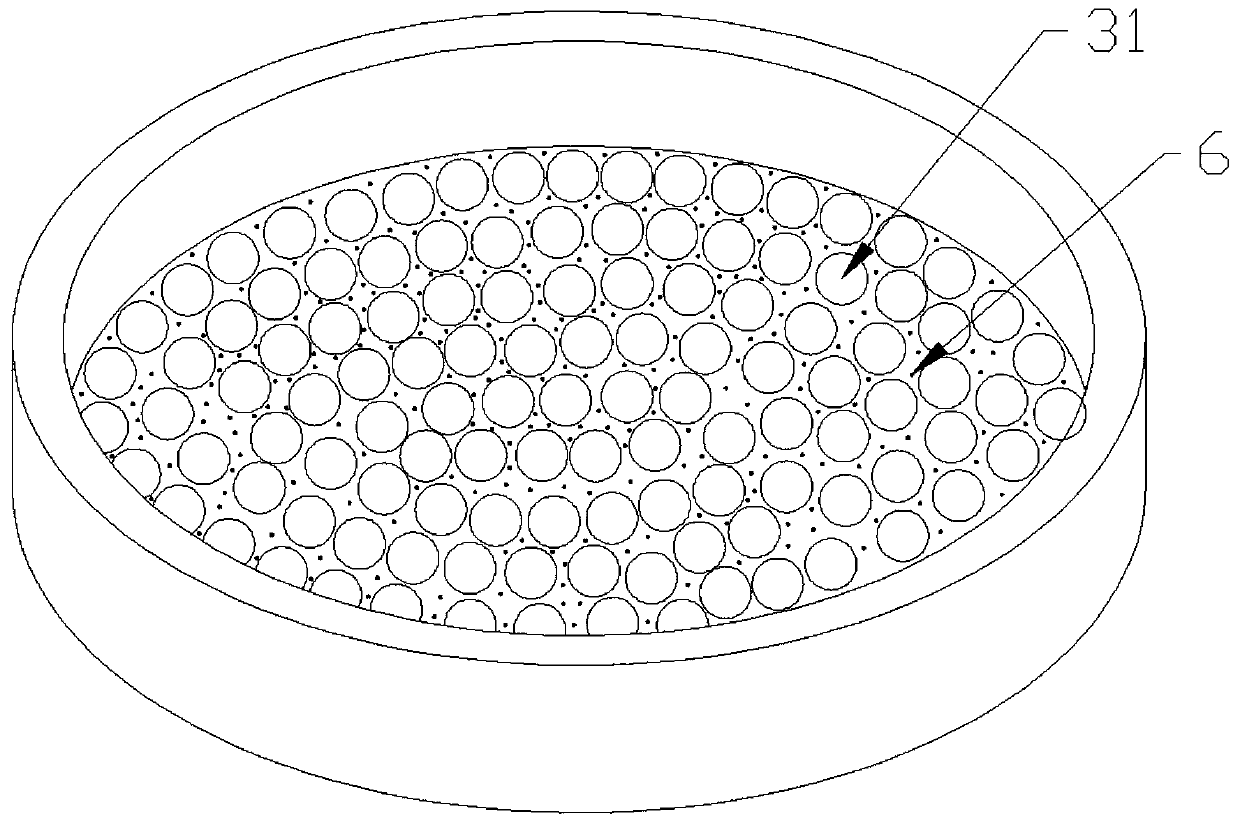

[0021] Such as figure 1 As shown, a calibration device and calibration method for a laser dust detector, the device is as follows, including: a base (1), characterized in that it also includes a detection chamber (2), a dust chamber (3), and a vibration machine (5), vibrating screen (6), buffer glass beads (31), dust cover (32), DC vibrator (5), the bottom of the magnetic base (1) is provided with a detection port (7), including: Laser method detection hole (71), weighing method detection hole (72); the detection chamber (2) is embedded in the base (1), the wall is provided with a detection hole (4), and the dust generation chamber (3) is connected to Above the detection chamber (2).

[0022] Preferably, the base (1) and the detection chamber (2) are circular in shape and the detection cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com