Automatic calibration device and automatic calibration method for ultrasonic probe

An automatic calibration and ultrasonic technology, applied in the direction of measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve the problems of long time consumption and low work efficiency, and achieve efficiency improvement, heavy weight, and automation The effect of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

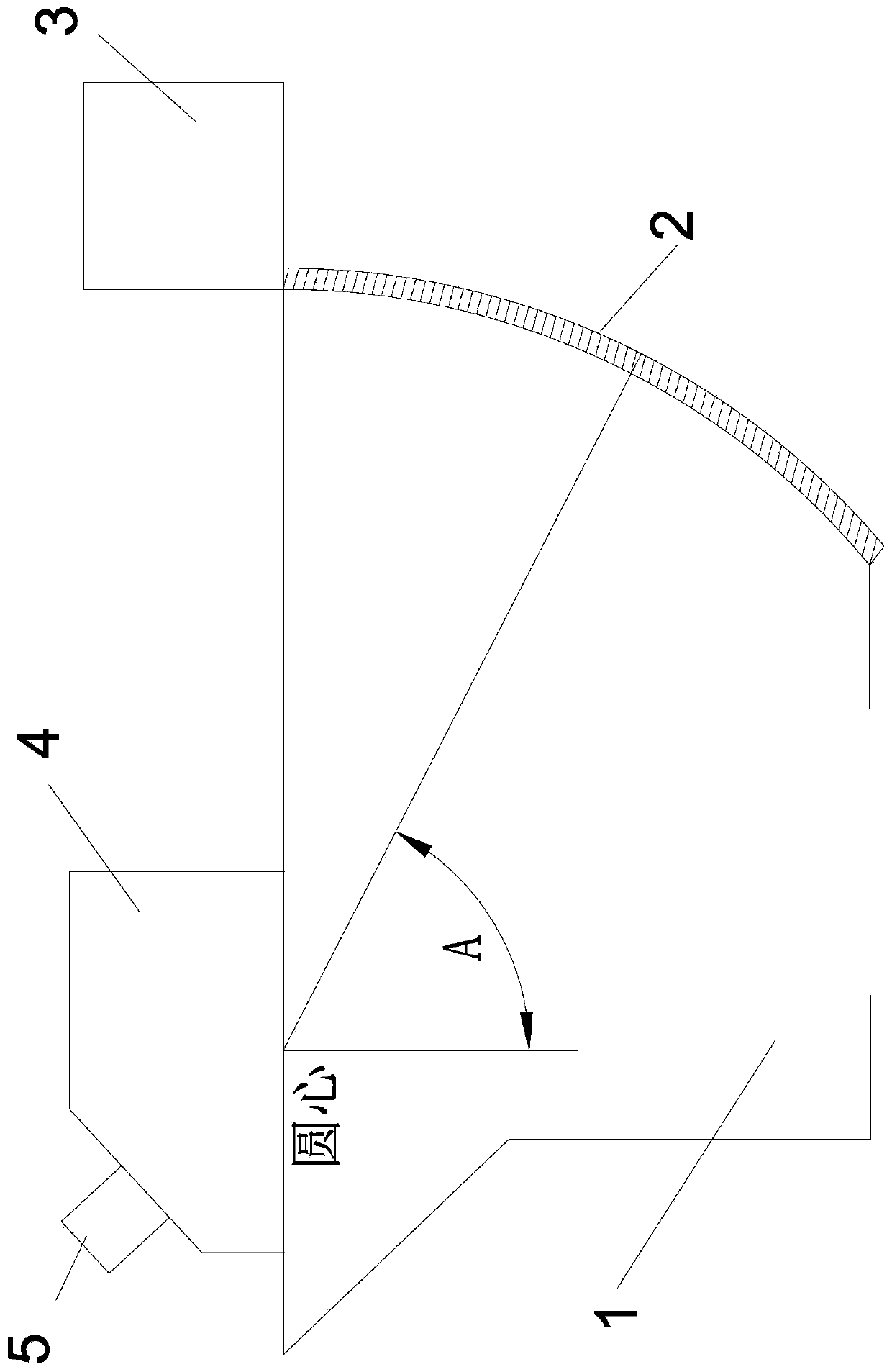

[0029] Existing methods for measuring the length of the leading edge of the probe (such as Figure 5 Shown): Put the probe on the test block (CSK-IA test block) 1, move the probe to find the maximum reflected wave of the radius of the arc surface on the right side of the test block (100mm), the length of the front edge of the probe is 100mm minus the front end of the probe to The distance from the edge of the test block, the position of the center of the circle at this time is the incident point of the sound beam of the probe. The determination of the K value of the probe is carried out by using the round hole on the left side of the test block (the measurement method is according to the manufacturer's instructions).

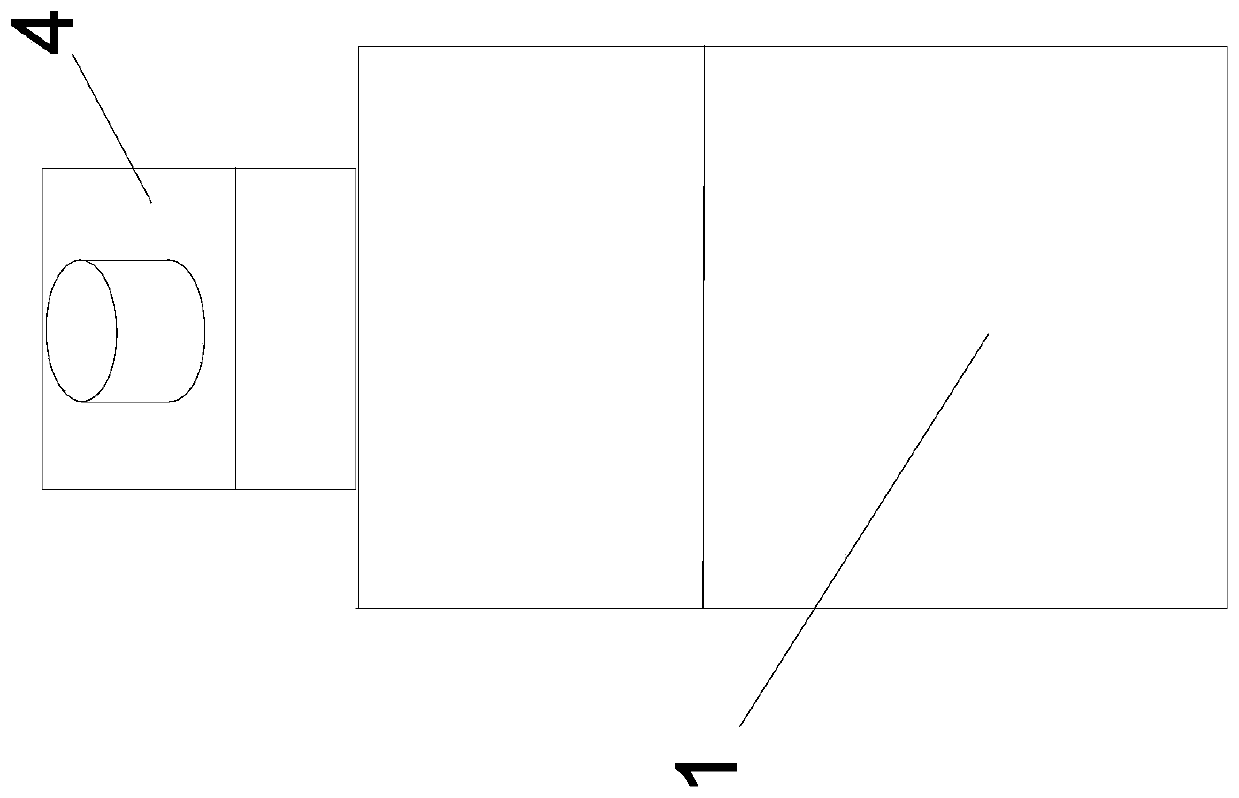

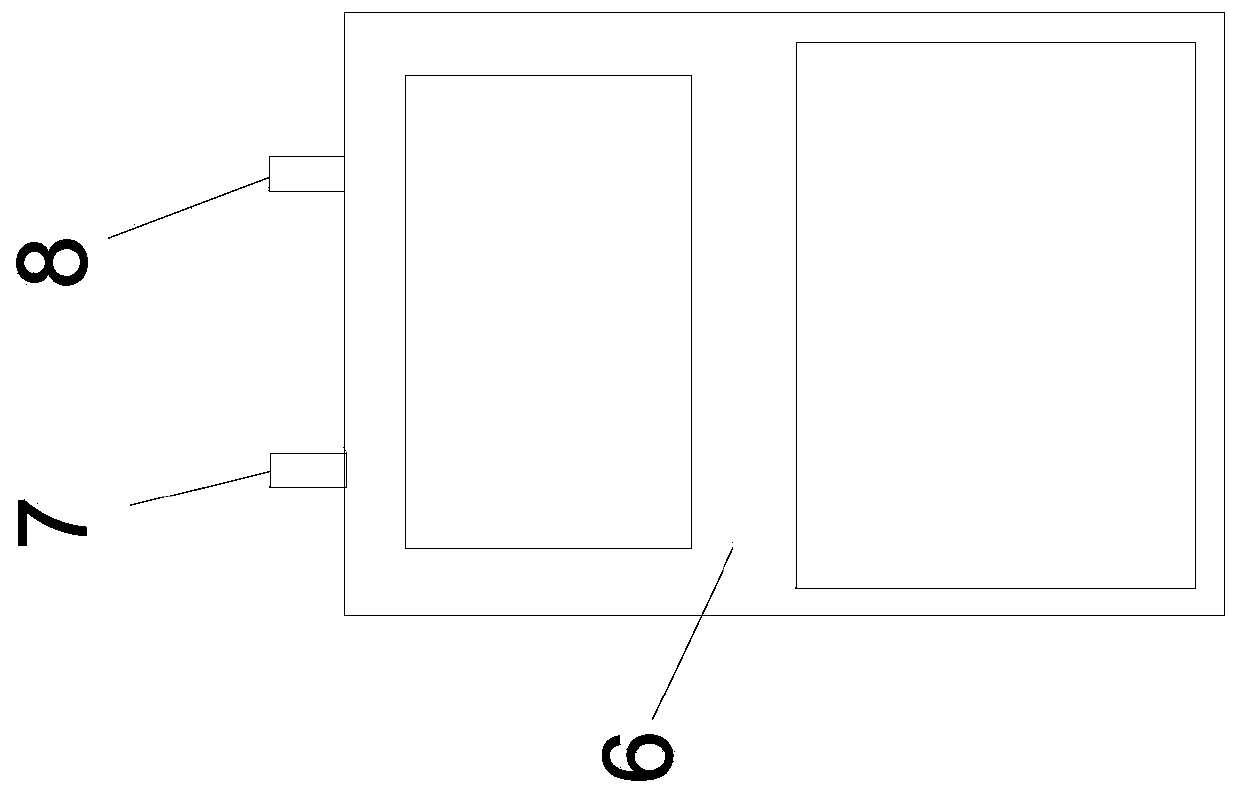

[0030] The ultrasonic probe automatic calibration device provided by the invention comprises the test block (similar to the standard CSK-IA ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com