Fertilizing device and facility capable of crushing and mixing fertilizer

A fertilization device and fertilizer mixing technology, applied in fertilization devices, fertilizer distributors, grain processing, etc., can solve problems such as blockage of fertilization devices, influence on fertilization stability, operation efficiency and quality, and caking, etc., to increase disturbance capacity , to achieve the effect of stable transportation and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

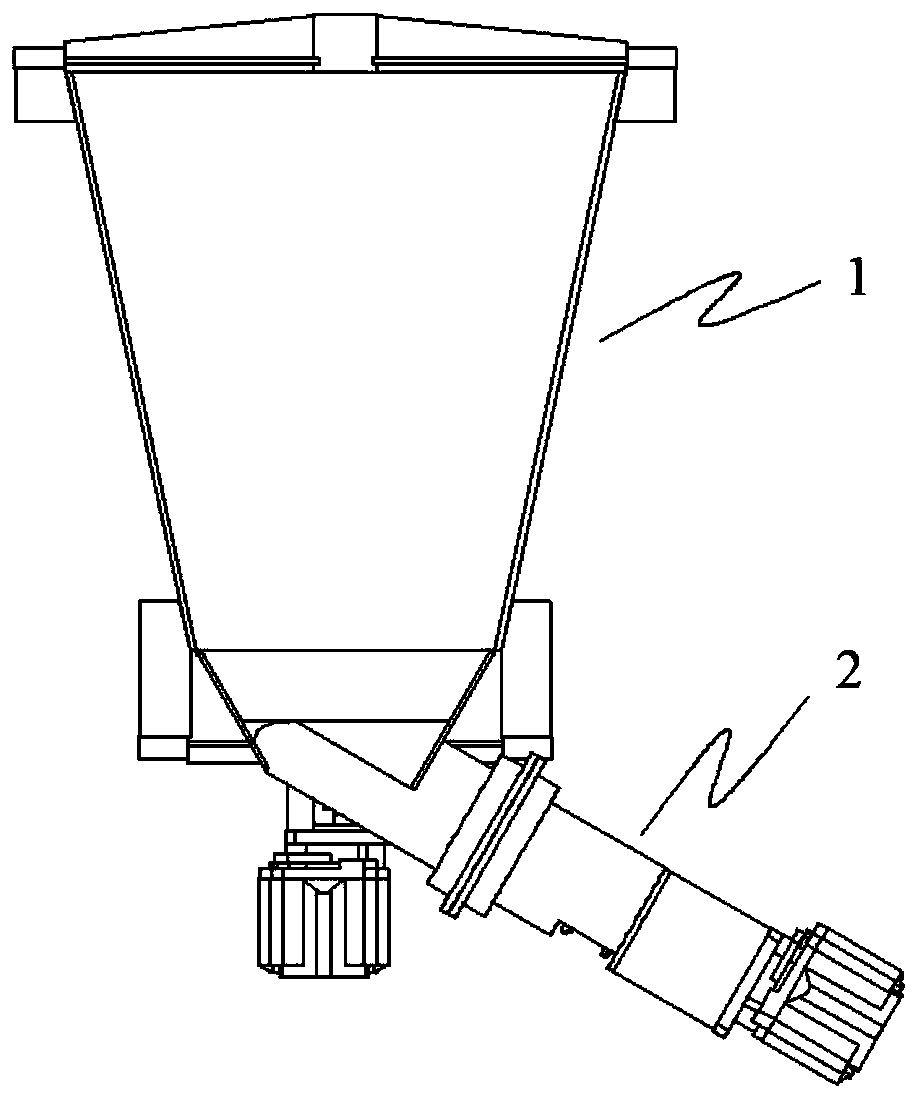

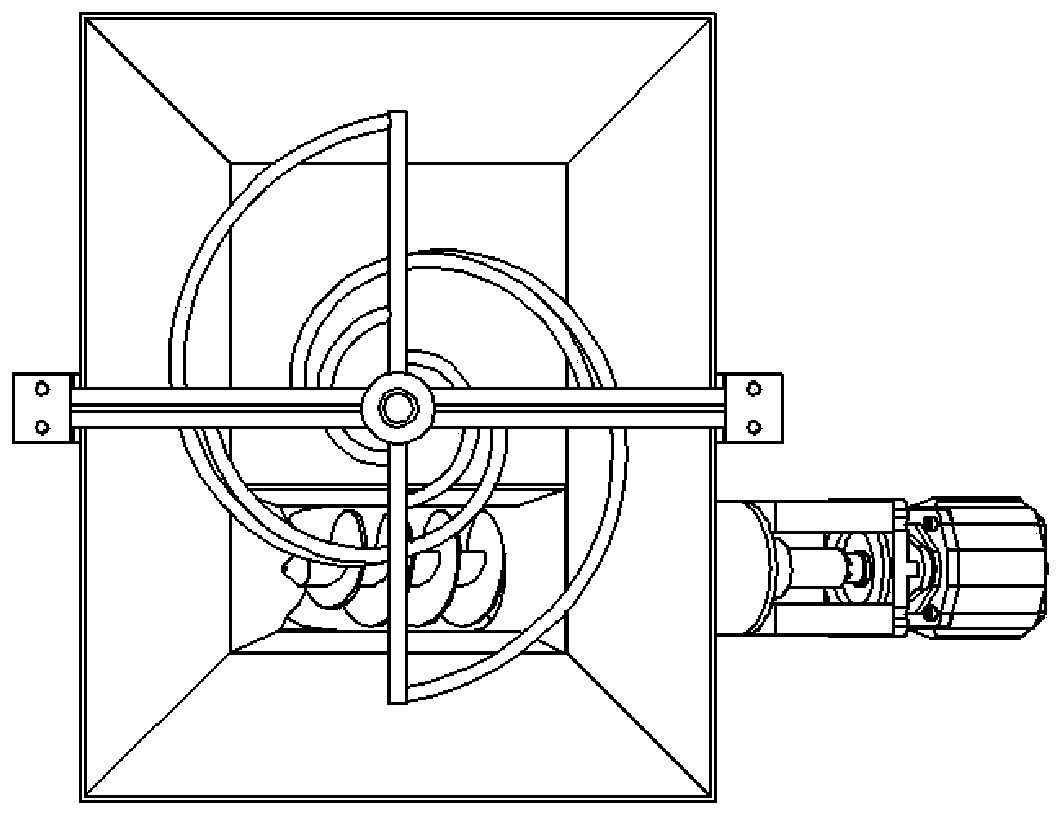

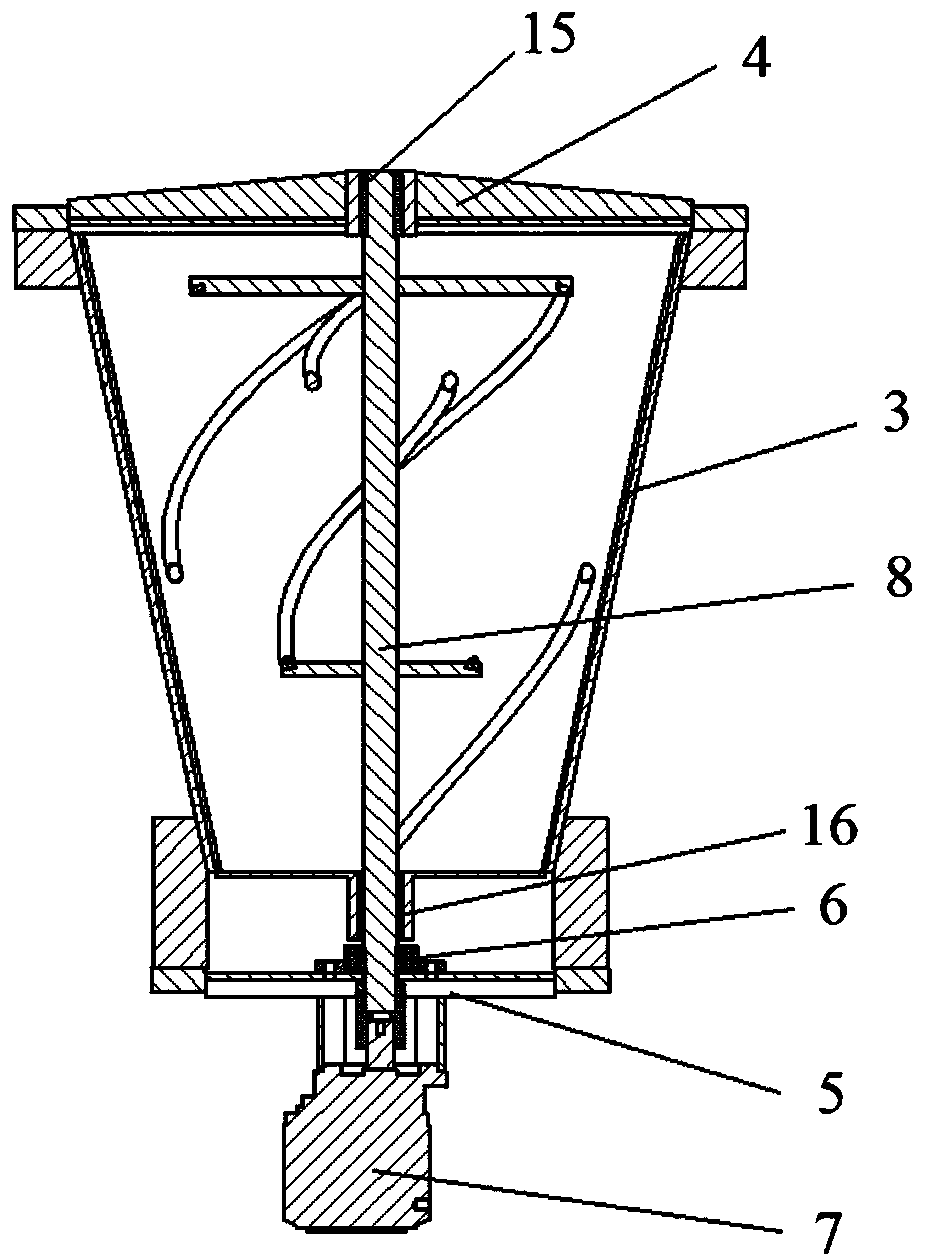

[0039] Attached below Figure 1-Figure 12 The present invention is described in detail, specifically, the structure is as follows:

[0040] This embodiment provides a fertilization device with the function of crushing and mixing fertilizer, including a crushing and mixing mechanism 1 and a fertilizer discharging mechanism 2 , and the fertilizer discharging mechanism 2 is installed below the crushing and mixing mechanism 1 . The crushing and mixing mechanism 1 adopts hydraulic power, which can realize the crushing of the agglomerated large pieces of fertilizer during the fertilization operation and the uniform mixing of the fertilizer during the mixed application of various fertilizers. The fertilizer discharge mechanism 2 adopts hydraulic power to realize the stable transportation of fertilizer and the operation stability of fertilizer discharge amount. The fertilizer breaking and mixing mechanism 1 and the fertilizer discharging mechanism 2 are independently hydraulically dr...

Embodiment 2

[0052] This embodiment provides a fertilization device with the function of crushing and mixing fertilizer, including the fertilizing device and the mobile device described in the first embodiment, the fertilizing device and the mobile device are detachably connected, and the fertilizing device can fertilize during the moving process through the mobile device.

[0053] In this embodiment, the moving device may be a tractor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com