A feeding and spraying device for liquid additives

A technology of liquid additives and spraying devices, which is applied in the direction of liquid spraying devices, spraying devices, spraying devices with movable outlets, etc., which can solve the problems of inconvenient operation, affecting feed quality, and low efficiency of liquid additives, and achieve the improvement of adding efficiency , easy to operate and easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

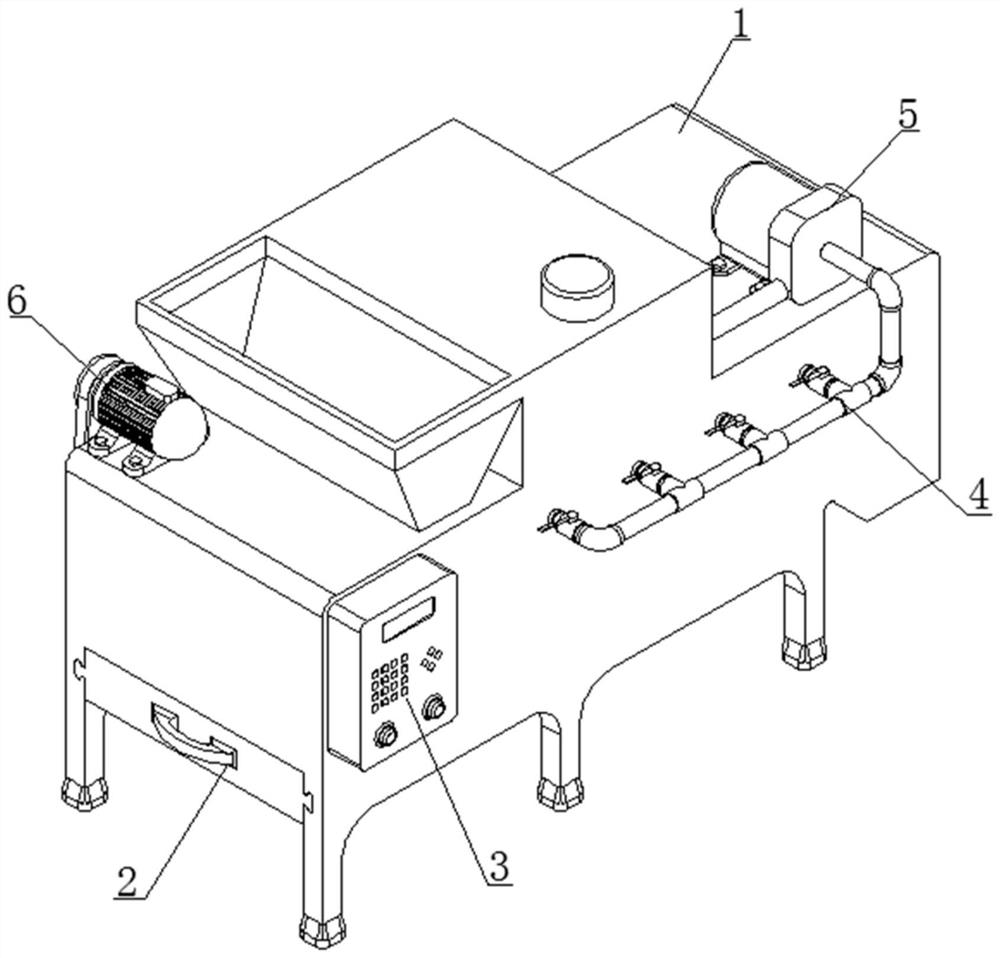

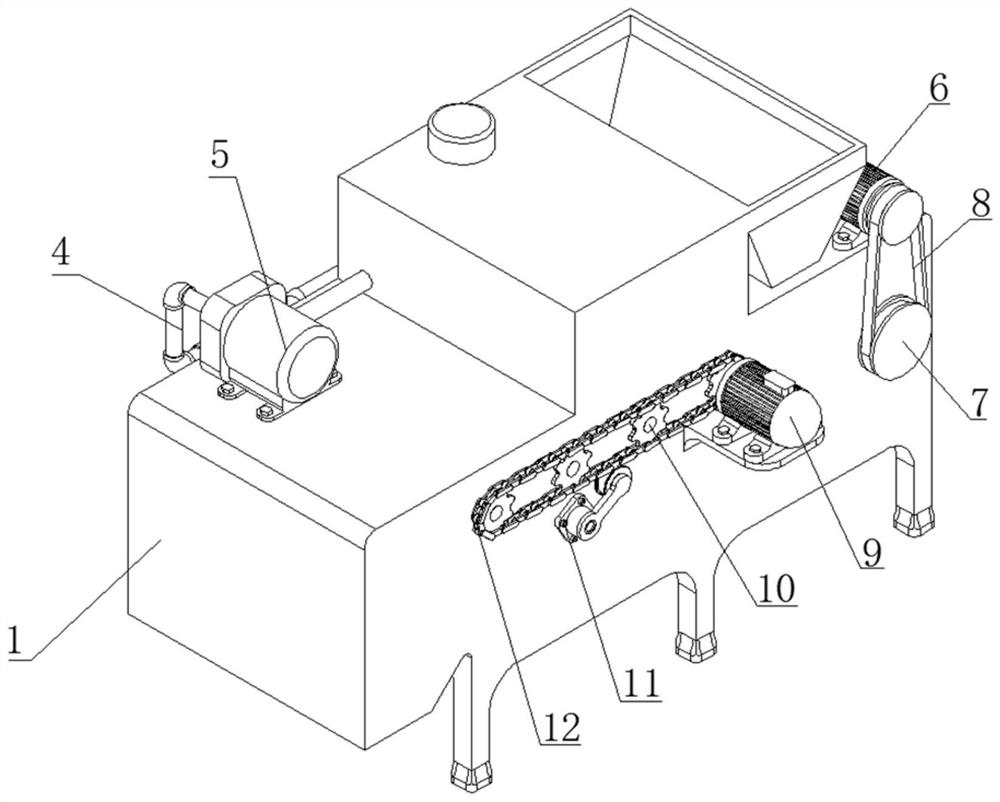

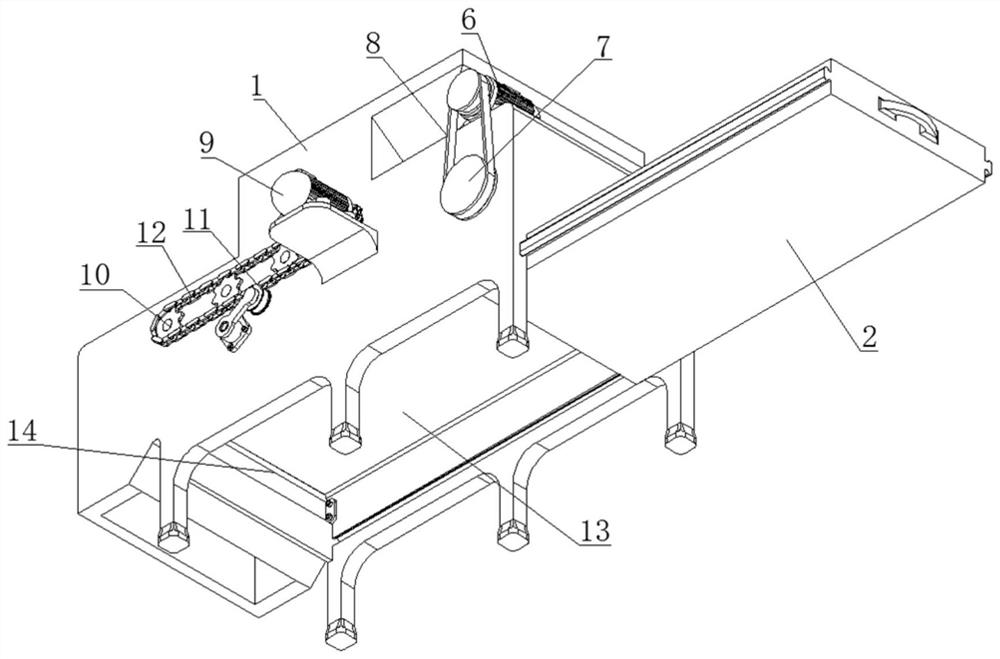

[0034] Example: refer to figure 1 , figure 2 with image 3 Shown: a feeding spray device for liquid additives, including body 1, receiving box 2, control box 3, connecting pipe 4, water pump 5, first motor 6, drive shaft 7, belt 8, second motor 9, spraying Wheel 10, tensioning pulley 11, chain 12, conveyor belt 13 and scraper 14; body 1 bottom end is equipped with receiving box 2, body 1 side near the front end is provided with control box 3, body 1 is provided with control box 3 One side is provided with a connecting pipe 4, the top of the body 1 is provided with a water pump 5, the water pump 5 and the connecting pipe 4 are connected together, the front end of the body 1 is provided with a first motor 6, and the inside of the body 1 is provided with a conveyor belt 13, and the two ends of the conveyor belt 13 are provided with There is a drive shaft 7, and the first motor 6 and the drive shaft 7 are connected by a belt 8. Inside the body 1, there are several spraying whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com